HEX150PB Heat Exchanger Instruction Manual

Page 9

8. Safety

9. Accessory

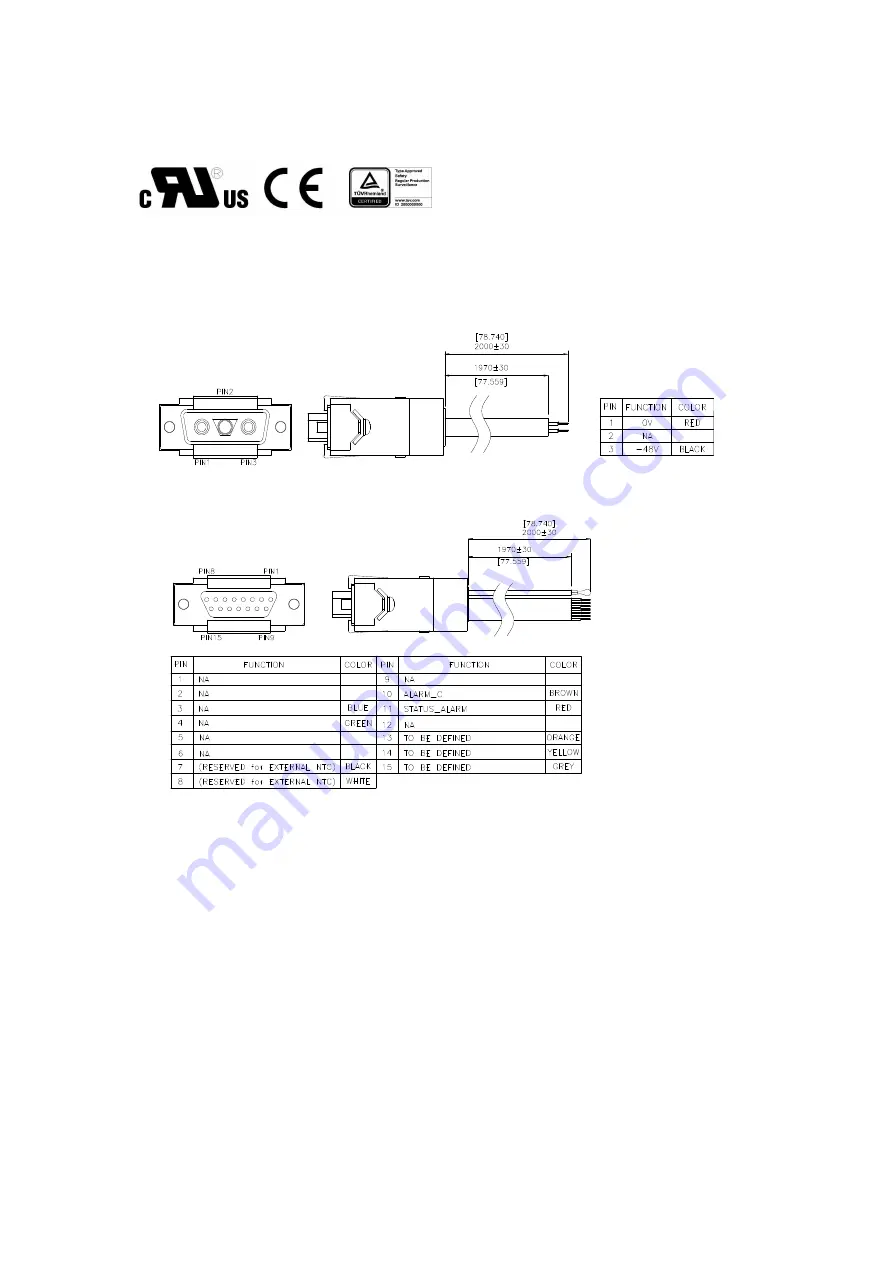

9-1. Power cable

9-2. Function cable

10. General Safety and Warnings

* Some electronic parts have a high operating temperature .

Use caution at all times.

* Incorrect installation may cause damage and/or injury.

* Installation and maintenance should be performed only by qualified

personnel . Use caution at all times.

* Ensure the grounding wire is connected before powering on the system.

* Ensure the cover and the mounting hardware are secure upon installation.

* All the cables connected to the unit must confirm to UL standards.