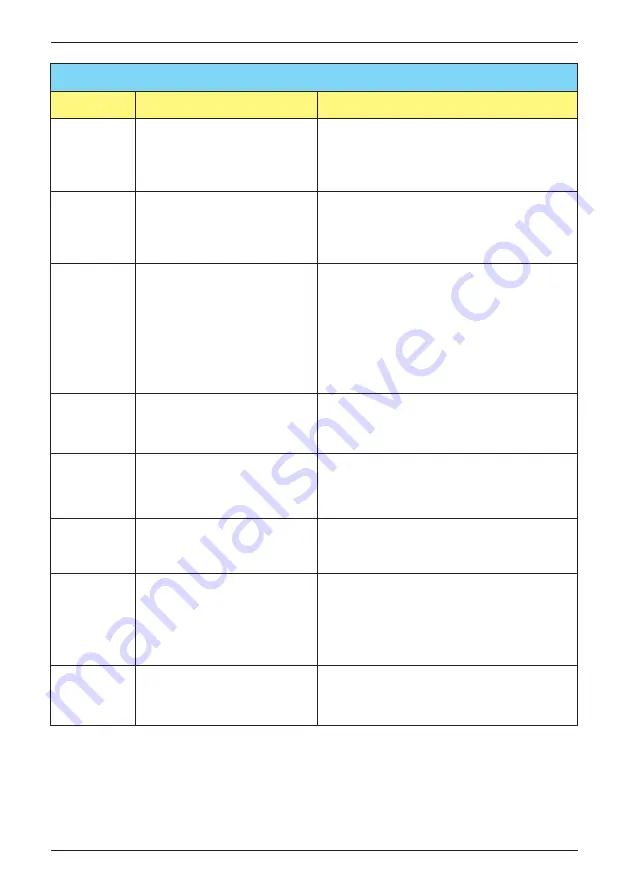

FAULT

Message

Possible cause

Action

HW CT B Fail

(F43)

1. Test current loop is broken

2. CTP4 is defective

3. Detection circuit malfunction

HW CT C Fail

(F44)

1. Test current loop is broken

2. CTP5 is defective

3. Detection circuit malfunction

1. Large Grid harmonics

2. Switching device is defective

3. Detection circuit malfunction

1. Check the utility waveform. Grid connection

of inverter need to be far away from

non-linear load if necessary

2. Check all switching devices in inverter

stage

3. Contact our customer service for

technical support

HW AC OCR

(F45)

One or more DC relays are

abnormal

Please contact our customer service for

technical support

HW DC RLY

(F76)

DC Cur. High

(F60, F61,

F70, F71)

1. Switching device in boost

is defective

2. Driver for boost is defective

3. Input current detection

circuit malfunction

1. Check all switching device in boost

2. Check the driver circuit for boost inside

the inverter

3. Check input current detection circuit

Contact our customer service for

technical support

Contact our customer service for

technical support

AFCI Circuit

Fail

(F58)

1. AFCI is not installed.

2. AFCI self-test is fail.

Check the AFCI detection circuit board for

making sure it is conneted correctly

HW ZC Fail

(F50)

The detection circuit for

synchronal signal malfunction

Check the detection circuit for synchronal

signal inside the inverter

AFCI Fault

(F59)

The inverter detects Arcing

occurs.

Check cables for replacement

85

Error message and Trouble Shooting

Summary of Contents for M88 Series

Page 2: ......

Page 29: ...Figure 3 16 AC gland assembling for M88H_122 Torque 0 8 N m to fix the screw 29 Installation ...

Page 96: ......

Page 97: ...M88H 操作手冊 三相併網型變流器 The power behind competitiveness www deltaww com English 1 97 繁體中文 ...

Page 117: ...要使用遮蔽板 請參考圖3 9的安裝方式 鎖附扭力45 kgf cm 圖3 9 遮蔽板的安裝方法 117 安裝 ...

Page 124: ...圖3 16 M88H_122交流固定頭的組裝方式 Torque 0 8 N m to fix the screw 安裝 124 ...

Page 163: ...圖5 5 AC DC SPD 損壞時的告警 圖5 6 拔起連接線並移除螺絲 AC SPD DC SPD 163 維護 ...

Page 169: ...圖5 14 拆卸功率模組風扇 僅以單側為例 組裝所需的螺釘扭矩 8 kgf cm 0 8N m 169 維護 ...

Page 170: ...圖5 15 濾網拆卸方向 圖5 15為濾網位置 170 維護 ...

Page 174: ...7 卸下8顆螺絲並用手抓住功率模組使其與配線箱分開 8 確定密封蓋有蓋上 圖5 18 拆下8顆螺絲後 將配線箱與功率模組分離 174 維護 ...

Page 191: ......

Page 192: ...Version 04201204 ...