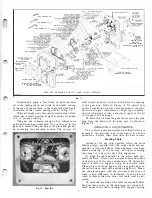

Fig.

25.

sure bar up or down by turning the adjusting nuts with

a wrench until it just touches the surface of the piece

of wood. When making this adjustment be sure to

turn each adjusting nut the same amount.

Place the rubber pressure pad, special steel washer

and the special hexagon nut on each of the studs. To

apply pressure hold the adjusting nut in position with

a wrench so it will not turn with one hand and tighten

the special hexagon nut with the other hand until the

desired amount of pressure is obtained. Be sure to

apply the same amount of pressure on each side of the

bar when making this setting. Refer to Fig. 22.

Installation and Adjustment of New Gears

The cutter head with bearings, housing, and knife

blades must be removed first, see Figure 38. Drain oil

Fig.

26.

12

Fig.

27.

from gear box by removing pipe plug as shown in

Figure 20. Then remove gear box and cover plate.

See Figure 1 1 . It is also necessary to remove the roller

chain, by disassembling the connective link in each

chain length.

The sprocket gear shaft assembly PLR-342-S, con

sists of the gear shaft, clutch, thrust washer, sprocket

worm gear, oil slinger, clutch sprocket, key spacer,

thrust bearing, and snap ring. The intermediate gear

shaft assembly PLR-343-S consists of intermediate

gear shaft, intermediate gear, ball bearing, support

block, snap ring, and set screws. These two shafts are

assembled at the factory, each as a unit, and are shipped

as a unit, under PLR numbers given above.

Figure 25 shows how these two shafts are to be

assembled in the gear box. The intermediate gear will

mesh with the sprocket worm gear when in position,

5-29-51

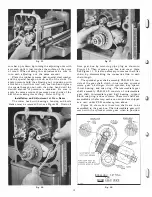

BACKLASH SETTING

FOR

WORM GEAR DRIVE

Fig.

28.

Summary of Contents for Milwaukee PM-1738

Page 1: ...13x5 INCH DELTA MILWAUKEE 7 7 1M rJ6fiUAKJ PM 1738 ...

Page 2: ......

Page 27: ......

Page 28: ......