Fig.

29.

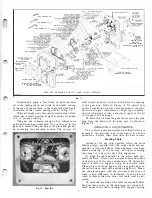

it will be necessary therefore, to hold them in that

position, that is, the intermediate gear over the sprock

et worm gear, when placing them in the casting. The

shaft support PLR-343 will go in one hole and the

sprocket gear shaft will go into another hole, see

Figure 26. The intermediate gear shaft is held in place

with the shaft support and lock plate PLR-94 and

three cap screws, as shown in Figure 30. The sprocket

gear shaft is held in place with lock plate PLR-394 and

one cap screw. These lock plates and cap screws are

.fastened to the two shafts from the inside of the planer

as shown in Figure 30. The infeed roller and guide plate

will have to be raised high enough to clear hole in

which lock plate PLR-94 will be inserted and fastened

to the shaft support with three cap screws. The lock

plate for the sprocket gear is located directly below

the cutter head. Do not tighten the cap screws in the

lock plates at this time. To raise the infeed roller, place

a 2

x

4 wood block

x

4" long under the infeed roller as

shown in Figure 30, and raise the table.

After these two gear shafts have been installed,

replace the cutter head. The Hi-speed worm on cutter

head shaft must mesh with Hi-speed worm on inter

mediate shaft as shown in Figure 26. After all of these

gears and worm drives are in place a certain amount

of backlash is allowed as shown in Figure 28. It is very

important that the backlash is �et right.

Fig.

30.

13

Fig.

3 1.

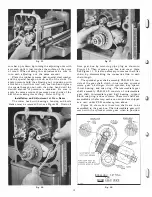

First tighten intermediate shaft, in shaft support,

with the two lock nuts, using two wrenches as shown

in Figure 26. After the intermediate shaft has been

tightened it is then held in place with socket head set

screw to keep the shaft from turning, see Figure 27.

Fig.

32.

Summary of Contents for Milwaukee PM-1738

Page 1: ...13x5 INCH DELTA MILWAUKEE 7 7 1M rJ6fiUAKJ PM 1738 ...

Page 2: ......

Page 27: ......

Page 28: ......