SP-2653 STR AIGHT KEY

MOTOR

""\/

-�:C·--

0

\

LEG CASTING PLR-8

PANEL

,ceo'

LEG CASTING

PLR-8

SCREW

SIDE

.

PLR-IO

MACH. SCREW

(l6)PLR-73

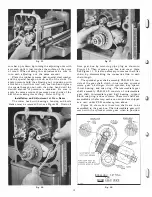

Convenient location of the ralsmg and lowering

mechanism of the table on the left side of the machine

permits the table to be raised or lowered in a mini

mum amount of effort and time.

Conveniently mounting the finished size scale on

the left side of the machine eliminates any unnecessary

bending and eye strain on the part of the operator when

making the table setting required. This scale has been

made very legible and is accurately graduated.

To compensate for wear of the table sliding in

relation to the right and left-hand columns, we have

incorporated into this machine steel table gibs to main

tain its original tight sliding fit at all times. These

gibs can be drawn up by means of three adjusting

screws on each side of the table casting.

The unique clutch mechanism enables the operator

to stop and start the feed instantly without shutting

off the motor.

The chip breaker and the pressure bar completely

guard the cutter head and feed rolls to insure maximum

protection to the operator and can be easily removed

for accessibility to these parts. In addition, the safety

type chip breaker design prevents the chips from being

thrown on the operating side of the machine. It is

also made long enough to prevent the fingers of the

operator from coming in contact with the revolving

knife blades in the cutter head if he should ever grasp

it from the operating side of the machine.

The serrated in-feed and the smooth out-feed rolls

are provided with compression springs so they can

be readily adjusted for planing any type of stock.

Positive stops are provided to eliminate the table

from striking the revolving knife blades in the cutter

head when adjusting it for planing thin material.

The motor bracket of the sub-base assembly has

(4) SP-1604 WASHER

SPLIT LOCKWASHER

(4) SP-1703

HEXAGON NUT (4) SP-1207

SPUT LOCKWASHER (4) SP-1709

H E XAGON NUT (2) SP-1207

SUB- BASE AND MOTOR BRACKET ASSEMBLY

Fig.

2.

2

holes provided in it to receive No. 224 and No. 225

standard NEMA frame motors.

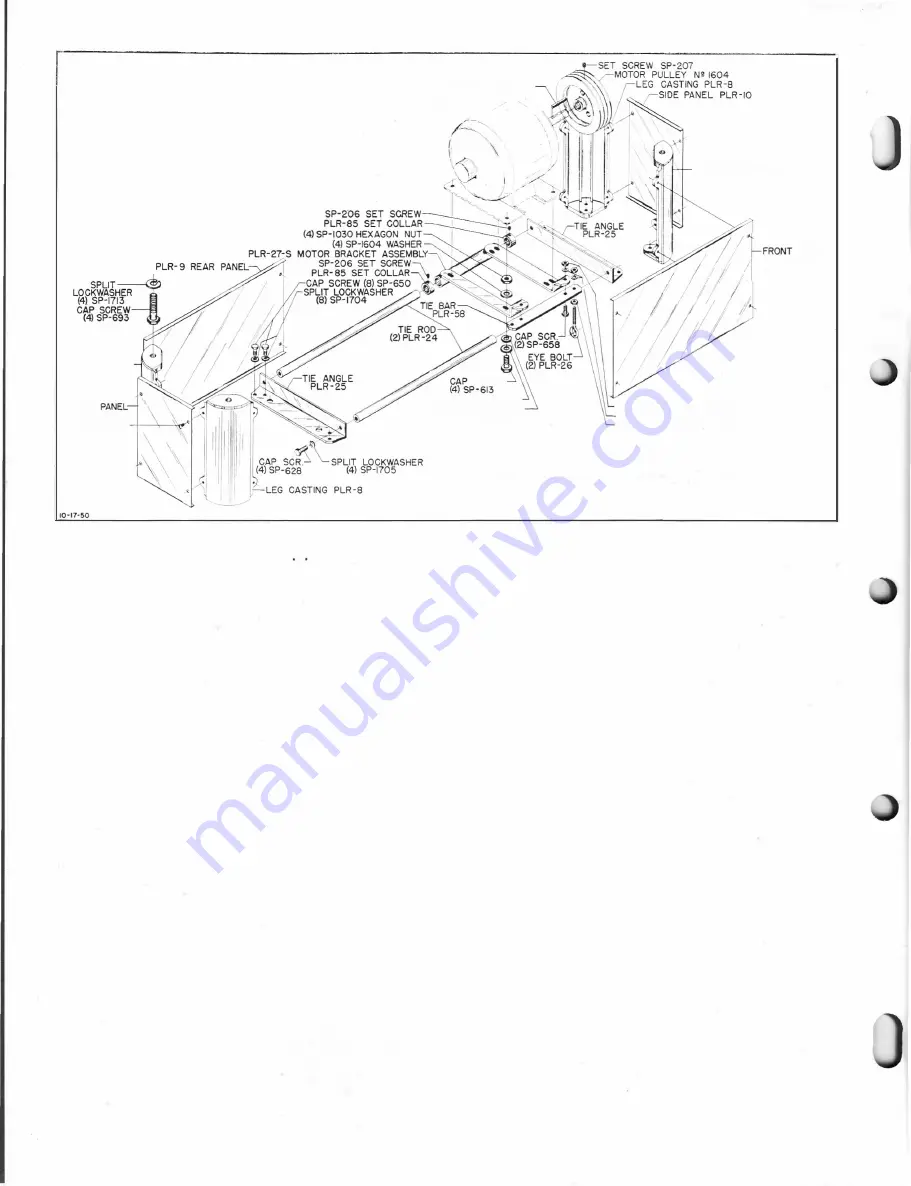

The feed mechanism is fully enclosed within the

gear box. The positive powerful drive consists of a

continuous anti-friction roller chain which connect

solid steel sprockets. One chain assembly is driven by

a double worm gear reduction drive which in turn is

driven by the cutter head. The cutter head is driven

from the motor by means of a matched set of 3 V -belts.

POWER, SPEED AND FEED

Use a 3 hp motor for this machine. We have avail

able a 3 hp, single phase motor and a 3 hp, three

phase motor according to the customer's choice. We

recommend using the three phase motor whenever the

power is available.

The correct motor speed with 60 cycle power is

1725 rpm, which will run the cutter head at 4200 rpm.

This speed is obtained with a 3 23/64" diameter cutter

head pulley in conjunction with the 7" motor pulley

No. 1604 furnished as standard equipment.

For 50 and 25 cycle current, use a 1 425 rpm motor

to run the cutter head at 4200 rpm. This speed is

obtained with a 3 23/64" diameter cutter head pulley

furnished as standard equipment and an 8Yz" motor

pulley No. 22-105 which is available and can be pur

chased extra.

The cutter head running at 4200 rpm takes 12,600

cuts per minute. The feed rate is 14 lineal feet per

minute and 75 cuts are taken on each inch of ma

terial feed to produce a veneer finish which is so smooth

that all subsequent sanding is held down to a minimum.

All motor pulleys furnished for this machine have

a 1 " bore and a

Y4"

keyway. They fit any of tl;!e Delta

motors recommended for this machine. Consult your

Delta dealer for the correct motor to meet your needs.

Summary of Contents for Milwaukee PM-1738

Page 1: ...13x5 INCH DELTA MILWAUKEE 7 7 1M rJ6fiUAKJ PM 1738 ...

Page 2: ......

Page 27: ......

Page 28: ......