21

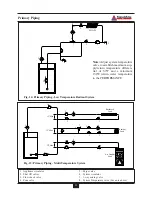

Primary Piping

For proper operation of the expansion tank

and system, remove the factory installed

automatic air vent from the PERFOR-

MANCE and plug the connection. (See

Item 10, Fig. 46 page 70)

DO NOT install automatic air vents on a

closed-type expansion tank system. Air

must remain in the system and be

returned to the expansion tank to pro-

vide an air cushion. An automatic air

vent would cause air to be vented from

the system resulting in a water-logged

expansion tank.

Circulator

The PERFORMANCE is supplied with a

circulator that is pre-wired to allow for

domestic priority. Locate the circulator in

the return or supply piping as shown in the

piping diagrams included in this manual.

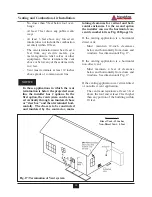

Closet (Zero Clearance) Applications

For applications in closets or zero clear-

ances, the installer may use the upper prima-

ry connection shown as Item 4 on page 70 as

a primary return connection. The air elimi-

nation, expansion tank and make-up water

system should then be piped directly into the

primary loop of the space heating prior to

the system circulator.

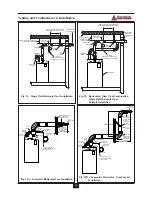

Sizing Primary Piping

See Figs: 12 through 15, pages 24 - 25, for

recommended piping arrangements based

on various applications. In all diagrams,

the space heating system is isolated from

the PERFORMANCE using primary / sec-

ondary piping connections.

Size the piping and system components

required in the space heating system using

recognized design methods.

System Piping - Zone Circulators

Connect the PERFORMANCE to the sys-

tem piping as shown in Fig. 12 page 24

when zoning with zone circulators. The

circulator supplied with the PERFOR-

MANCE should not be used for a heat

zone. It must supply only the primary loop.

Install a separate circulator for each zone of

space heating.

To control the zone circulators refer to Fig.

34, page 47.

To ensure adequate flow rate through

the PERFORMANCE, maintain a mini-

mum 1 inch diameter on the system pip-

ing connecting the unit to and from the

primary / secondary connection.

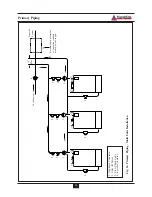

System Piping - Zone Valves

Connect the PERFORMANCE to the sys-

tem piping as shown in Fig. 13 page 24

when zoning with zone valves. The prima-

ry / secondary piping ensures the priority is

given to the production of domestic hot

water.

To control the system circulator refer to

Fig. 33, page 46.

To ensure adequate flow rate through

the PERFORMANCE, maintain a mini-

mum 1 inch diameter on the system pip-

ing connecting the unit to and from the

primary / secondary connection.

NOTICE

NOTICE

CAUTION