17- ENG

D27930

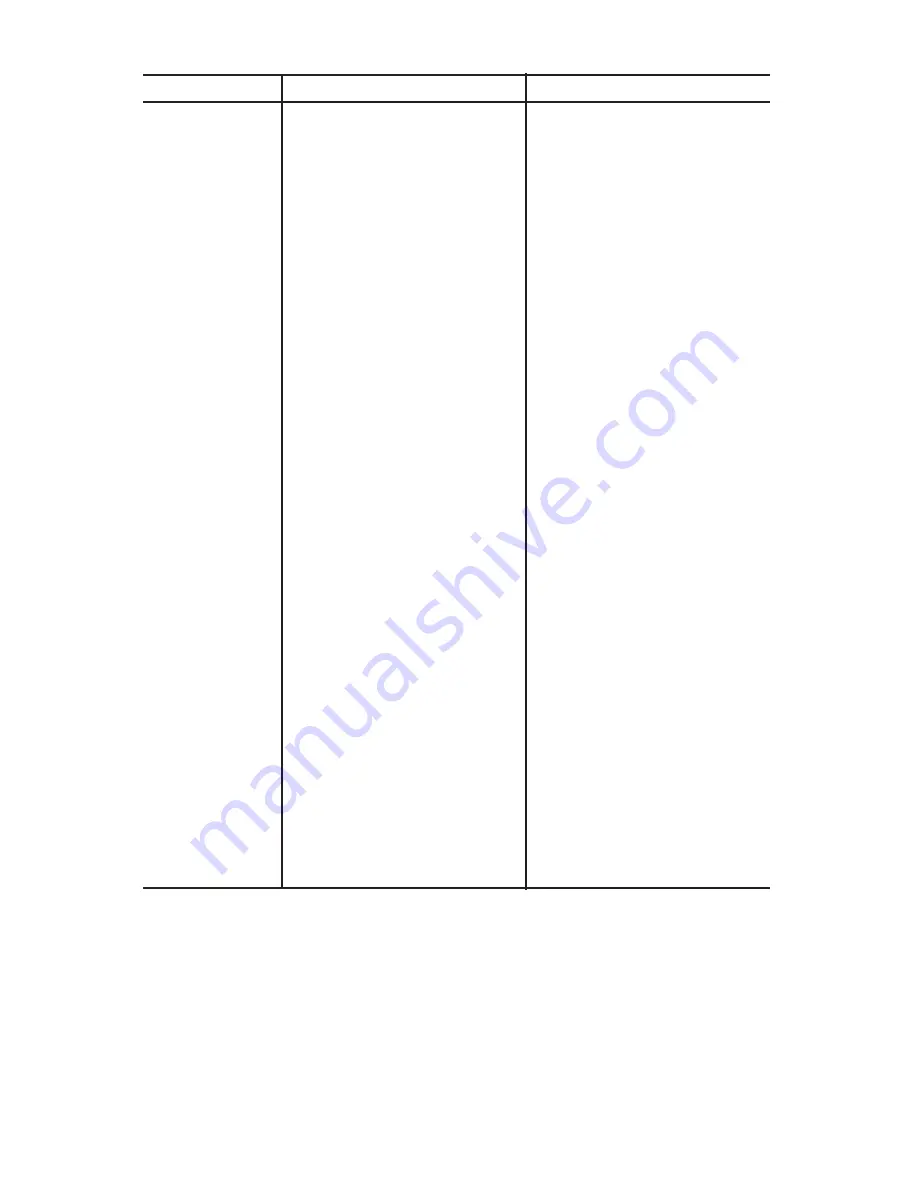

PROBLEM

CAUSE

CORRECTION

Motor will not

run.

Check fuse box for blown

fuse and replace as

necessary. Reset circuit

breaker. Do not use a fuse or

circuit breaker with higher

rating than that specified for

your particular branch circuit.

Check for proper fuse. You

should use a time delay fuse.

Check for low voltage

problem.

Check the extension cord.

Disconnect the other

electrical appliances from

circuit or operate the

compressor on its own

branch circuit.

Have checked by a Trained

Service Technician.

Fuse blown, circuit breaker

tripped.

Extension cord is wrong

length or gauge.

Faulty motor.

Check the extension cord.

Allow compressor to cool for

approximately 30 minutes so

thermal overload switch will

reset. If unit still does not

start, empty air from tank and

refer to "Thermal overload

protector cuts out

repeatedly" information.

Motor overheated

AIR COMPRESSOR REPAIR PARTS

For Parts, Service, Warranty or other Assistance, please call 1-866-422-4286.