3

During operation, the gate should not under any circumstances obstruct public path ways and roads (public area).

When using tools and small parts to install or carry out repair work on a gate exercise caution and do not wear rings, watches or loose clothing.

To avoid serious personal injury due to entrapments, remove any locking device fitted to the gate in order to prevent damage to the gate.

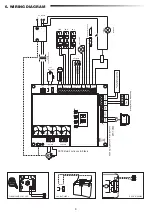

Installation and wiring must be in compliance with your local building and electrical installation regulations. Power cables must only be connected to a properly earthed

supply.

Disconnect electric power to the system before installation, maintenance, repairs or removing covers. A disconnecting device must be provided to the mains power supply

(permanently-wired installation) to guarantee all-pole disconnection (isolating switch or by a separate fuse). The repairs and electrical installations may be performed only

by an authorised electrician. Emergency Stop Button must be installed for emergency case based on the risk assessment.

Ensure that entrapment between the driven part and the surrounding fixed parts due to the opening movement of the driven part is avoided by respecting the given safety

distances in accordance with the EU: EN 13241, EN12604, EN 12453, EN 12635; GB (UK, NI) BS EN 13241, BS EN12604, BS EN 12453, BS EN12635 and/or with

safety devices (e.g. safety edge).

Testing of the safety function of the drive system is recommended to be carried out at least once a month. Refer also to manufacturers instruction of the gate system

components.

After the installation a final test of the full function of the system and the of the safety devices must be made and all users must be instructed in the function and operation

of the sliding gate operator.

Gate systems must meet the force limitation according EU: EN 12453, EN 60335-2-103; GB (UK, NI) BS EN 12453, BS EN 60335-2-103.

Additional safety device (safety edge,.) must be considered in accordance to the standard by changes to the system.

It is important to make sure that the gate always runs smoothly. Gates which stick or jam must be repaired immediately. Employ a qualified technician to repair the

gate, never attempt to repair it yourself. This device is not intended for use by persons (including children) with restricted physical, sensory or mental abilities or lack of

experience or knowledge, unless they are supervised by a person responsible for their safety or have received instruction in how to use the device. If necessary, control

equipment MUST be mounted within sight of the gate and out of reach of children. Children should be supervised to ensure that they do not play with the device. Do not

allow children to operate push button(s) or remote(s). Misuse of the gate operator system can result in serious injury.

The warning signs should be placed in clearly visible locations.

The gate opener should ONLY be used if the user can see the entire gate area and is assured that it is free of obstacles and the gate operator is set correctly. No one may

pass through the gate area while it is moving. Children must not be allowed to play in the vicinity of the gate.

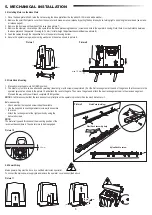

The full protection against potential crushing or entrapment must work immediately when the drive arms are installed.

There may be existing hazards on mechanical, electrical installation or the closing edges of the gate by crushing, impact points:

•

Structural failure, leaf, hinges, fixings, travel stops, wind load

•

Crush, hinge area, under the gate, safety distance on fixed object

• Electrical failure (Control – faults in safety systems)

• Impact, swept area, hold to run, force limitation, presence detection

Appropriate measures must be taken to ensure safe operation of the gate system according the standards.

Never start up a damaged drive.

Use the manual release only to disengage the drive and – if possible – ONLY when is gate closed. Operation of the emergency manual release can lead to uncontrolled

movements of the gate. The Timer-to-Close (TTC) feature, the myQ Smartphone Control app, are examples of unattended operation of the gate.

Any device or feature that allows the gate to close without being in the line of sight of the gate is considered as unattended open/close.

The Timer-to-Close (TTC) feature, the myQ Smartphone Control, and any other myQ devices can ONLY be activated when Liftmasters photo cells are installed (TTC

works only in close direction). The gate shall only be operated in the direct sight line to the gate.

IMPORTANT INFORMATION!

•

This procedure is also required on private installations (new or retrofitted to a manually operated gate).

This installation and operating manual must be retained by the user.

• The manufacturer accepts no liability/warranty claims resulting from use other than intended use and after the warranty expires.

• The legal remedy is the sole responsibility for all associated rights.

NOTE:

Observe the installation and operating manual.

• Always monitor the function of the system and rectify the cause immediately in the event of a malfunction.

• Carry out an annual inspection of the system. Call a specialist.

• Safety distances must be respected between the gate leaf and the environment in accordance with related standards.

• The operator can be installed Only on stable and rigid gate leaves. Gate leaves must not bend or twist when opening and closing.

• Assure that the hinges of the gate leaf are installed and working correctly and not creating any obstacles.

• Installation of two operators on same door leaf is strictly prohibited.

•

Observe the corresponding requirements of the local, national regulations for compliance with the measures to protect human health, which must be observed when

contacting other people, including employees, suppliers and customers (e.g. safety distance, mask requirement, etc).

•

Precise information can be requested from the local authorities.

1. SAFETY INSTRUCTIONS AND INTENDED USE