5

General information and conditions for set-up.

Before installing the gate operator ensure that the gate is running smoothly. The weight of the door is not allowed to be completely placed on the motor shaft.Ensure that

all the required cables (power cable, accessory cables etc) are prepared and laid correctly before the base plate is installed in the concrete.

NOTE:

All crushing points must be secured by an entrapment protection according the to EU: EN 12453, EN 60335-2-103; GB (UK, NI): BS EN 12453, BS EN 60335-2-103.

SL400EVK, SL600EVK, SL1000EVK

Herewith you start mechanical installation of the gate operator.

Mounting Plate

90 - 100 mm

Rack

GATE

Picture 2

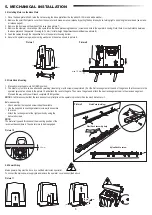

5.1 Dimensions of Gate and Operator

SL400EVK

5 m

400 kg

SL600EVK

8 m

600 kg

SL1000EVK

12 m

1000 kg

304

218

270

88

Picture 5

Picture 4

Picture 3

1. Take the anchor screw and put one nut untill the bottom of the tread. Add a washer and insert it from the bottom into base plate. Secure from top with a second nut.

2. Repeat for remaining 3 anchor screws (see picture 3).

3. Get the prepared cables (see picture 4) through the hole in the base plate.

4.

Set the base plate into prepared concrete work. Ensure the plate is poisitoned correctly to the gate respecting the required space to gate and rack (see picture 1). The

arrow on the base plate needs to show towards gate. Align the base palte and finalise the concrete work.

5. Let the concrete base dry for at least 24h before proceeding (see picture 5).

NOTE:

When installing a base plate ensure that later operator mounting and position adjustment with the setting screws is still possible at later stages if required.

5.2 Installing Base Plate

GATE

24h

5. MECHANICAL INSTALLATION

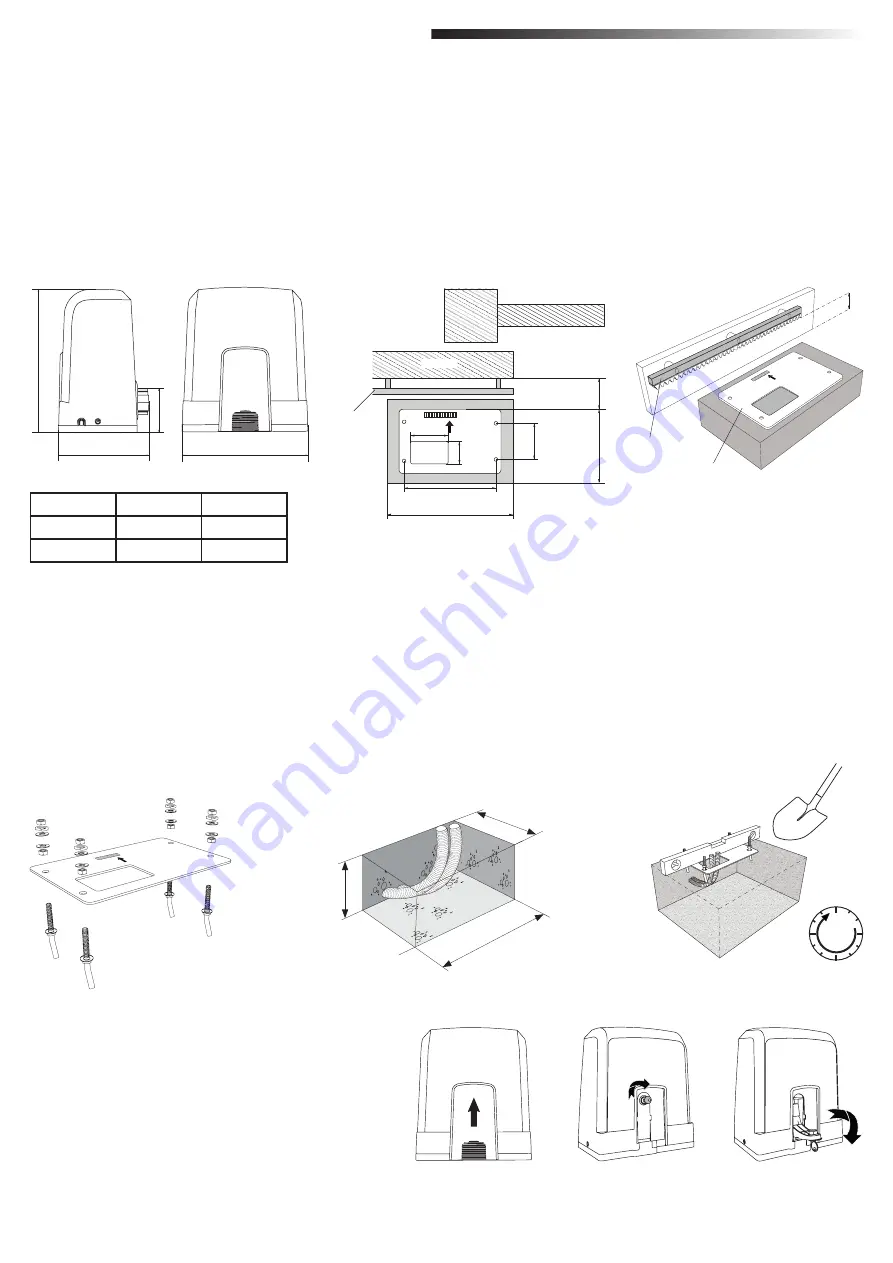

• Remove the small front plastic cover from the operator.

• Put the key into keyhole and turn it right 90°.

• Pull the lever down.

To re-engage the operator follow the procedure backwards.

5.3 Emergency Release Mechanism

Picture 6

Rack

Gate

60

270

170

104

60

244

100

GATE

Picture 1