HD32.1

- 67 -

V2.1

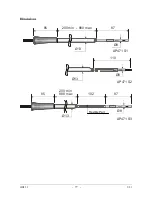

TP3227K probe composed of 2 standalone temperature probes, Pt100 sensor and TP3227PC

probe composed of 2 standalone temperature probes, Pt100 sensor:

•

Adjustment of the sensors at 1.10 m, 0.60 m and 0.10 m:

Screw the telescopic rod code

TP3227.2 L=450mm

to the probe

TP3227.

Once the rod has been

fastened on the clamp, adjust the height to 1.10m for the fixed sensor. The sliding probe should

be placed at 0.60 m from the floor. You should use the combined ankle/floor probe

TP3227PC

to perform the measurements at 0.10 m from the floor.

Combined probe for radiant temperature measurement TP3207TR

The face of the probe marked by the symbol is the air flow hot side. It should be oriented

toward the hot source (wall/wall ceiling/floor or floor/ceiling).

6.2

P

ROBES FOR THE

O

PERATING

P

ROGRAM

C:

P

HYSICAL

Q

UANTITIES

6.2.1 Temperature measurement using the probe Pt100 complete with SICRAM module

The instrument works with temperature probes fitted with the SICRAM module (with a Platinum

Pt100 sensor with 100

Ω

resistance at 0°C). The excitation current was chosen in order to minimize

the sensor self-heating effects. The SICRAM module acts as an interface between the sensor on the

probe and the instrument. There is a microprocessor circuit with a permanent memory inside the

module that enables the instrument to recognize the type of probe connected and to read its

calibration information.

Upon turning on the instrument automatically detects the probes fitted with SICRAM module:

The probes are detected during turn on, and this cannot be performed when the instrument is

already on, therefore if a probe is connected and the instrument is on, it is necessary to turn it

off and on

.

In all versions the temperature sensor is housed in the end part of the probe.

The response time for the measurement of the temperature in air is greatly reduced if the air is

moving. If the air is still, stir the probe back and forth. The response times are longer than those for

liquid measurements.

The temperature measurement by

immersion

is carried out by inserting the probe in the liquid for at

least 60mm; the sensor is housed in the end part of the probe.

In the temperature measurement by

penetration

the probe tip must be inserted to a depth of at least

60mm, the sensor is housed in the end part of the probe. when measuring the temperature on frozen

blocks it is convenient to use a mechanical tool to bore a cavity in which to insert the tip probe.

In order to perform a correct

contact

measurement, the measurement surface must be even and

smooth, and the probe must be perpendicular to the measurement plane. A contact measurement is

hard to perform due to various factors: The operator must be experienced in handling the probe and

consider all the factors influencing it.

So as to obtain the correct measurement, the insertion of a drop of oil or heat-conductive

paste is useful (do not use water or solvents). This method improves the response time, in

addition to accuracy.

The °C or °F unit of measurement can be chosen for display, printing, and logging.

The sensor is calibrated in the factory, and the Callendar Van Dusen parameters are recorded

in the SICRAM module.

Summary of Contents for HD32.1

Page 6: ...HD32 1 6 V2 1 Thermal Microclimate HD32 1...

Page 78: ...HD32 1 78 V2 1 MIN 350 MAX 1020 120 AP471 S4...

Page 106: ...HD32 1 106 V2 1 Moderate Environment Norm ISO 7730...

Page 107: ...HD32 1 107 V2 1 Moderate Environment Norm ISO 7730...

Page 108: ...HD32 1 108 V2 1 Moderate Environment Norm ISO 7730...

Page 109: ...HD32 1 109 V2 1 Moderate Environment Norm ISO 7730...

Page 110: ...HD32 1 110 V2 1 Moderate Environment Norm ISO 7730...

Page 111: ...HD32 1 111 V2 1 Moderate Environment Norm ISO 7730...

Page 112: ...HD32 1 112 V2 1 12 2 WARM ENVIRONMENT Norm ISO 7243 Norm ISO 7243...

Page 113: ...HD32 1 113 V2 1 Warm Environment Norm ISO 7243...

Page 114: ...HD32 1 114 V2 1 Warm Environment Norm ISO 7243 Norm ISO 7243...

Page 115: ...HD32 1 115 V2 1 Warm Environment Norm ISO 7243...

Page 116: ...HD32 1 116 V2 1 Warm Environment Norm ISO 7243...

Page 117: ...HD32 1 117 V2 1 Warm Environment Norm ISO 7243...

Page 118: ...HD32 1 118 V2 1 12 3 DISCOMFORT ANALYSIS Norm ISO 7730 Norm ISO 7730...

Page 119: ...HD32 1 119 V2 1 Discomfort Analysis Norm ISO 7730...

Page 120: ...HD32 1 120 V2 1 Discomfort Analysis Norm ISO 7730...

Page 121: ...HD32 1 121 V2 1 Discomfort Analysis Norm ISO 7730...

Page 122: ...HD32 1 122 V2 1 Discomfort Analysis Norm ISO 7730...

Page 123: ...HD32 1 123 V2 1 Discomfort Analysis Norm ISO 7730...

Page 124: ...HD32 1 124 V2 1 Discomfort Analysis Norm ISO 7730...

Page 125: ...HD32 1 125 V2 1 12 4 HOT ENVIRONMENT Norm ISO 7933 Norm ISO 7933...

Page 126: ...HD32 1 126 V2 1 Hot Environment Norm ISO 7933...

Page 127: ...HD32 1 127 V2 1 Hot Environment Norm ISO 7933...

Page 128: ...HD32 1 128 V2 1 Hot Environment Norm ISO 7933...

Page 129: ...HD32 1 129 V2 1 Hot Environment Norm ISO 7933...

Page 130: ...HD32 1 130 V2 1 Hot Environment Norm ISO 7933...

Page 131: ...HD32 1 131 V2 1 Hot Environment Norm ISO 7933...

Page 132: ...HD32 1 132 V2 1 12 5 COLD ENVIRONMENT Norm ISO 11079 Norm ISO 11079...

Page 133: ...HD32 1 133 V2 1 Cold Environment Norm ISO 11079...

Page 134: ...HD32 1 134 V2 1 Cold Environment Norm ISO 11079...

Page 135: ...HD32 1 135 V2 1 Cold Environment Norm ISO 11079...

Page 136: ...HD32 1 136 V2 1 Cold Environment Norm ISO 11079...

Page 137: ...HD32 1 137 V2 1 Cold Environment Norm ISO 11079...

Page 138: ...HD32 1 138 V2 1 Cold Environment Norm ISO 11079...

Page 139: ...HD32 1 139 V2 1 Cold Environment Norm ISO 11079...

Page 140: ...HD32 1 140 V2 1 12 6 PHYSICAL QUANTITIES...

Page 153: ...HD32 1 153 V2 1 NOTES...

Page 154: ...HD32 1 154 V2 1 NOTES...

Page 155: ......