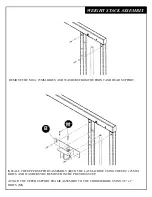

(SEE INSET)

ASSEMBLE THE 4 ½” PULLEY (

U

) INTO THE BOTTOM PULLEY FRAME

(

R

) USING THE M10 x 45MM BOLT (

DD

), M10 WASHERS (

II

), AND M10 LOCKNUT

(

KK

).

INSTALL TO BOTTOM FRAME (

C

) USING THE M10 x 65MM CARRIAGE BOLTS (

GG

),

M10 WASHERS (

II

), AND M10 LOCKNUTS (

KK

).

ATTACH THE REAT CROSSMEMBER (

N

) TO THE BOTTOM FRAME (

C

) USING THE

M12 x 70MM BOLTS (

AA

), M12 WASHERS (

HH

), AND M12 LOCKNUTS (

JJ

). INSTALL

THE RUBBER BOOTS (

T

) OVER THE ENDS OF THE CROSSMEMBER.

ATTACH THE FOOT PLATE

(C2)

AND FOOT REST

(C1)

TO THE BOTTOM FRAME

(C)

USING M10 x 70 MM FLAT HEAD BOLTS

(FF),

M10 WASHERS

(II),

AND M10 LOCK-

NUTS

(KK).

BOTTOM FRAME ASSEMBLY

TOOLS REQUIRED:

METRIC WRENCHES OR SOCKET SET

Some components may be pre-installed

from the factory

(NOTE: THE NUTS USED ON THIS

BENCH ARE LOCK NUTS, THIS MEANS

YOU MUST TIGHTEN THEM DOWN

PAST THE PLASTIC INSERT.)

U

DD

I I

I I

R

KK

AA

N

HH

HH

T

T

C

II

KK

JJ

GG

II

KK

I I

KK

C2

C2

FF