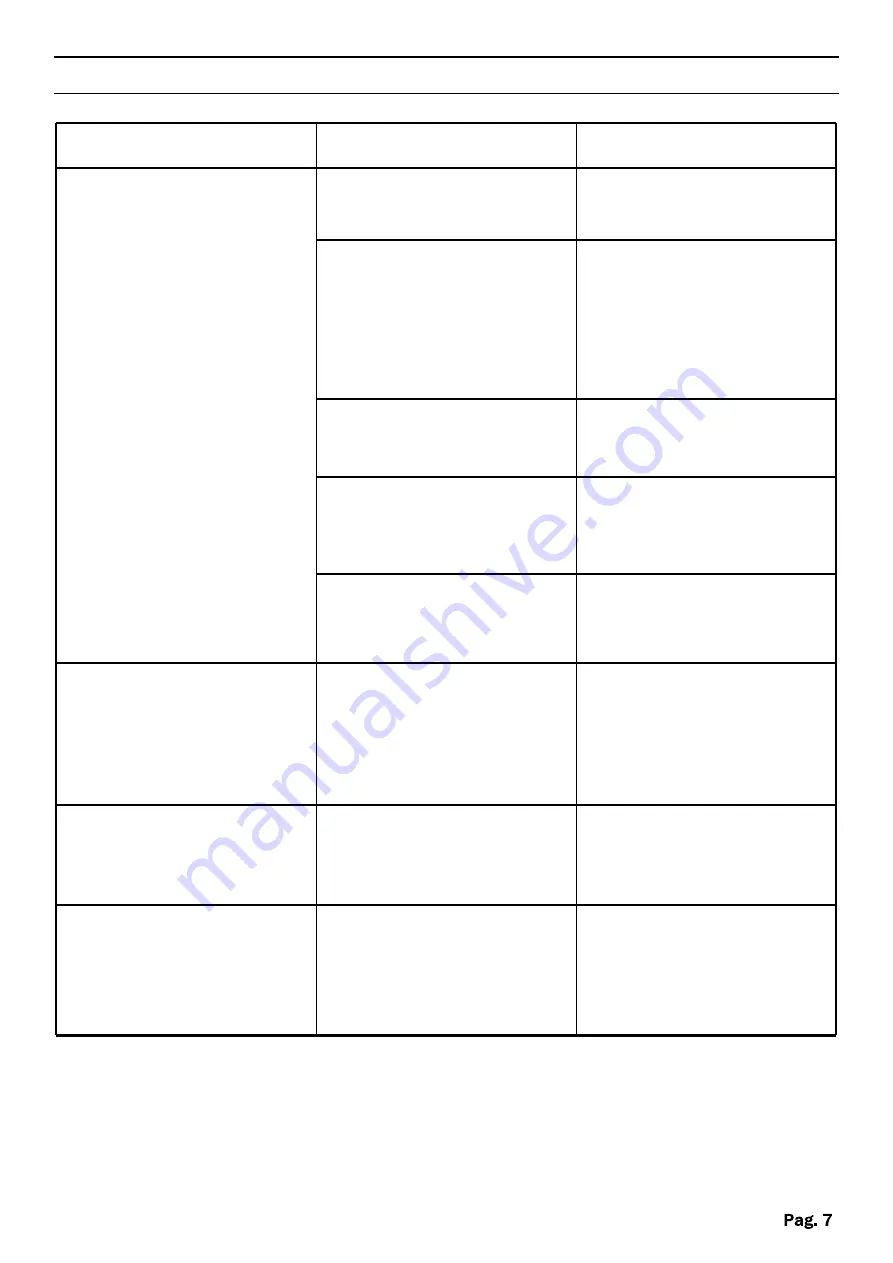

TROUBLESHOOTING

PROBLEM

PROBABLE CAUSE

SOLUTION

On giving a command with

the remote

control or with the

key-switch, the gate

doesn’t open or the motor

doesn’t start

230 volt mains voltage

absent

Check master switch

Emergency STOP present

Check for any STOP

selectors or commands.

If not used, check jumper

on STOP contact input on

the control board

Fuse blown

Replace with one of same

value.

Power cable of motor or

motors not

connected or faulty.

Connect the cable to

appropriate

terminal or replace.

The photocell is not

functioning or the

beam is interrupted

Check the connection,

remove any

obstacle across the beam

On giving a command with

the remote control, the

gate doesn’t open but

works with the key

command

The remote control has not

been

memorised or the battery

is flat

Carry out the remote

control learning

procedure on the radio

receiver or replace the

battery with a new one..

The gate starts, but stops

immediately

The force of the motor or

motors is insufficient

Modify the value with the

FORCE trimmer on the

control unit

One wing opens and the

other closes

The connection is not

correct

Invert the connection of

the cable of the motor

which rotates in the wrong

sense

N.B. - If the problem persists, contact your Retailer or the nearest Service

Centre