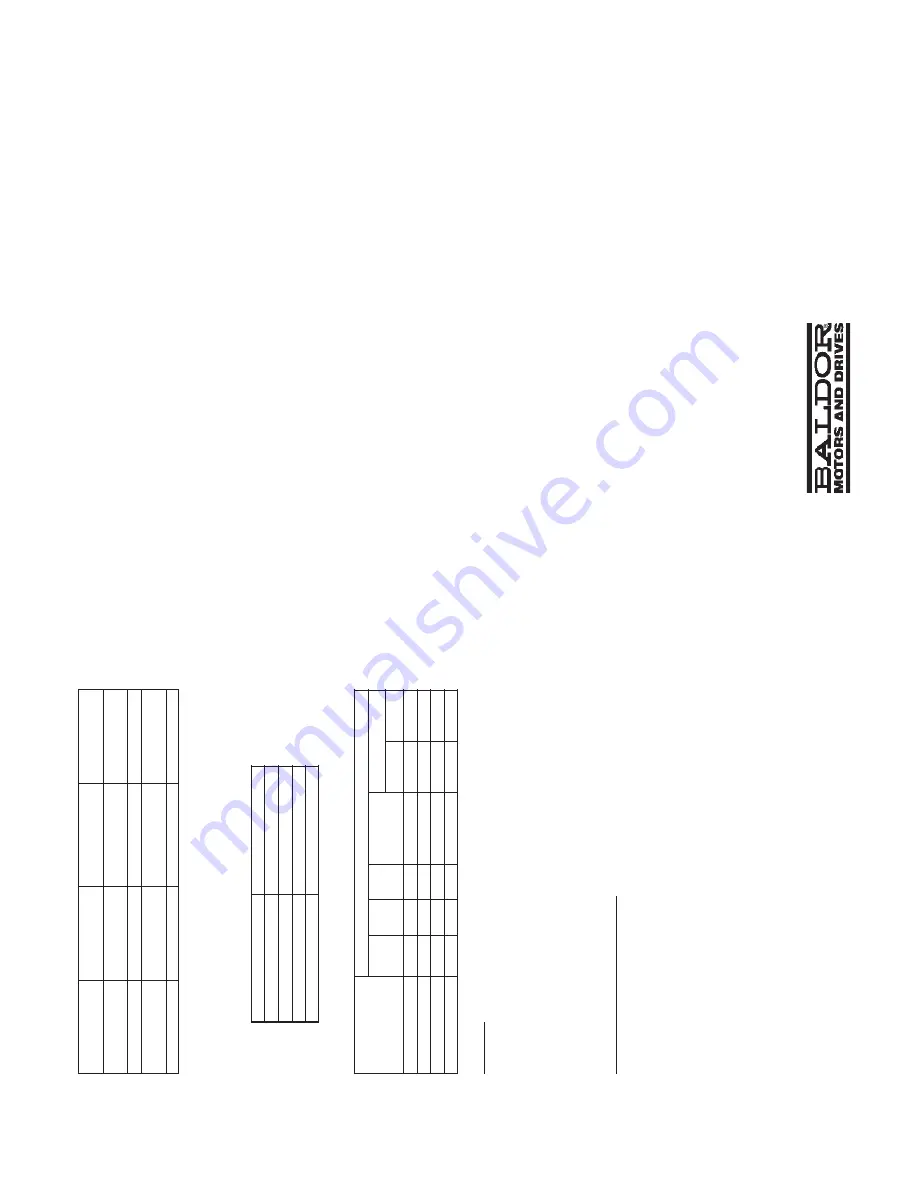

T

able 2 Service Conditions

Severity

of Service

Ambient T

emperature

Maximum

Atmospheric Contamination

Type of Bearing

Standard

40

°

C

Clean, Little Corrosion

Deep Groove Ball

Bearing

Severe

50

°

C

Moderate dirt, Corrosion

Ball Thrust, Roller

Extreme

>50

°

C* or

Class H Insulation

Severe dirt, Abrasive

dust, Corrosion

All Bearings

Low T

emperature

<-30

°

C **

*

Special high temperatur

e

gr

ease is r

ecommended.

**

Special low temperatur

e

gr

ease is r

ecommended.

T

able

3

Lubrication Interval Multiplier

Severity

of Service

Multiplier

Standard

1.0

Severe

0.5

Extreme

0.1

Low T

emperature

1.0

T

able

4

A

m

ount of Grease to Add

Bearing Description (Largest bearing in each frame size)

Frame Size NEMA

(IEC)

Bearing

OD

Width

Weight of

grease

to

add

Volume of grease to add

(IEC)

Bearing

OD D mm

Width B

mm

grease to add ounce (gram)

inches

3

teaspoon

Up

to 210 incl. (132)

6307

80

21

0.30 (8.4)

0.6

2.0

Over 210 to 280 incl. (180)

631

1

120

29

0.61 (17.4)

1.2

3.9

Over 280 to 360 incl. (225)

6313

140

33

0.81 (23.1)

1.5

5.2

Over 360 to 5000 incl.(300)

NU322

240

50

2.12 (60.0)

4.1

13.4

Weight in grams = 0.005 DB

Procedure

Clean

the gr

ease fitting (or ar

ea ar

ound gr

ease hole, if equipped with slotted

gr

ease scr

ews). If motor has a purge plug, r

emove it. Motors can be

re

gr

eased while stopped (at less than 80

°

C) or running.

Apply gr

ease gun to fitting (or gr

ease hole). T

oo much gr

ease or injecting

gr

ease to quickly can cause pr

ematur

e bearing failur

e. Slowly apply the

recommended amount of gr

ease, taking 1 minute or so to apply

. Operate

motor f

or 20 minutes, then r

einstall purge plug if

pr

eviously r

emoved.

Caution: Keep gr

ease clean. Mixing dissimilar gr

ease is not r

ecommended.

Sample Relubrication Determination

This sample deter

mination is based on a NEMA 286T (IEC 180) motor

operating at 1750 RPM driving an exhaust fan in an ambient of 43

°

C

atmospher

e that is moderately corr

osive.

1.

Table 1 list 9500 hours for standar

d conditions.

2.

Table 2 classifies severity of service as Sever

e"

.

3.

Table 3 lists a multiplier value of 0.5 for Sever

e conditions.

4.

Table 4 shows that 1.2 in

3

or 3.9 teaspoon of gr

ease is to be added.

Note:

Smaller bearings in size categor

y may r

eq

uir

e r

educed amounts of

gr

ease.

P

.O. Box 2400

Fort Smith, AR 72902–2400 U.S.A.

(501) 646–471

1

LB5028

1/01

281

Summary of Contents for DP

Page 1: ...Operation Manual 2016 MODELS MSF DP DPSL DPXSL DPX4T DPX8T DPX12T DPX16GT Grain Dryer ...

Page 2: ......

Page 4: ...2 ...

Page 6: ...GENERAL 2 01 01 2016 Dryer Labels Location 4 ...

Page 7: ...GENERAL 3 01 01 2016 5 ...

Page 14: ...12 ...

Page 24: ...STARTUP 10 01 01 2016 Alarm Limit Indication Error Messages 22 ...

Page 25: ...STARTUP 11 01 01 2016 23 ...

Page 26: ...STARTUP 12 01 01 2016 24 ...

Page 32: ...STARTUP 18 01 01 2016 GRAIN SHRINKAGE TABLE SHRINKAGE WHEN GRAIN IS DRIED TO THESE LEVELS 30 ...

Page 46: ...STARTUP 32 01 01 2016 Alarm Limit Indication Error Messages 44 ...

Page 47: ...STARTUP 33 01 01 2016 45 ...

Page 50: ...48 ...

Page 74: ...72 ...

Page 76: ...74 ...

Page 80: ...78 ...

Page 131: ...129 ...

Page 132: ...130 ...

Page 144: ...142 ...

Page 168: ...166 ...

Page 178: ...176 ...

Page 179: ...177 ...

Page 180: ...178 ...

Page 181: ...179 ...

Page 182: ...180 ...

Page 183: ...181 ...

Page 184: ...182 ...

Page 185: ...183 ...

Page 186: ...184 ...

Page 187: ...185 ...

Page 188: ...186 ...

Page 189: ...187 ...

Page 190: ...188 ...

Page 191: ...189 ...

Page 192: ...190 ...

Page 193: ...191 ...

Page 194: ...192 ...

Page 195: ...193 ...

Page 196: ...194 ...

Page 197: ...195 ...

Page 198: ...196 ...

Page 199: ...197 ...

Page 200: ...198 ...

Page 201: ...199 ...

Page 202: ...200 ...

Page 203: ...201 ...

Page 204: ...202 ...

Page 205: ...203 ...

Page 206: ...204 ...

Page 207: ...205 ...

Page 220: ...218 ...

Page 221: ...219 ...

Page 222: ...220 ...

Page 223: ...221 ...

Page 278: ...ëë 276 ...

Page 286: ...2011 Service Manual Rev A 284 ...

Page 287: ...2011 Service Manual Rev A 285 ...

Page 288: ...2011 Service Manual Rev A 286 ...

Page 289: ...2011 Service Manual Rev A 287 ...

Page 290: ...2011 Service Manual Rev A 288 ...

Page 291: ...2011 Service Manual Rev A 289 ...

Page 292: ...2011 Service Manual Rev A 290 ...

Page 293: ...2011 Service Manual Rev A 291 ...

Page 294: ...2011 Service Manual Rev A 292 ...

Page 295: ...2011 Service Manual Rev A 293 ...

Page 296: ...2011 Service Manual Rev A 294 ...

Page 297: ...2011 Service Manual Rev A 295 ...

Page 298: ...2011 Service Manual Rev A 295 ...