4.8

Disengaging device

Fig. 8

The counterweight is used to manually relieve the pre-tension of the

dished washer stack.

The trolley and drive can be pushed along the track by hand when the

tension on the dished washer stack is released.

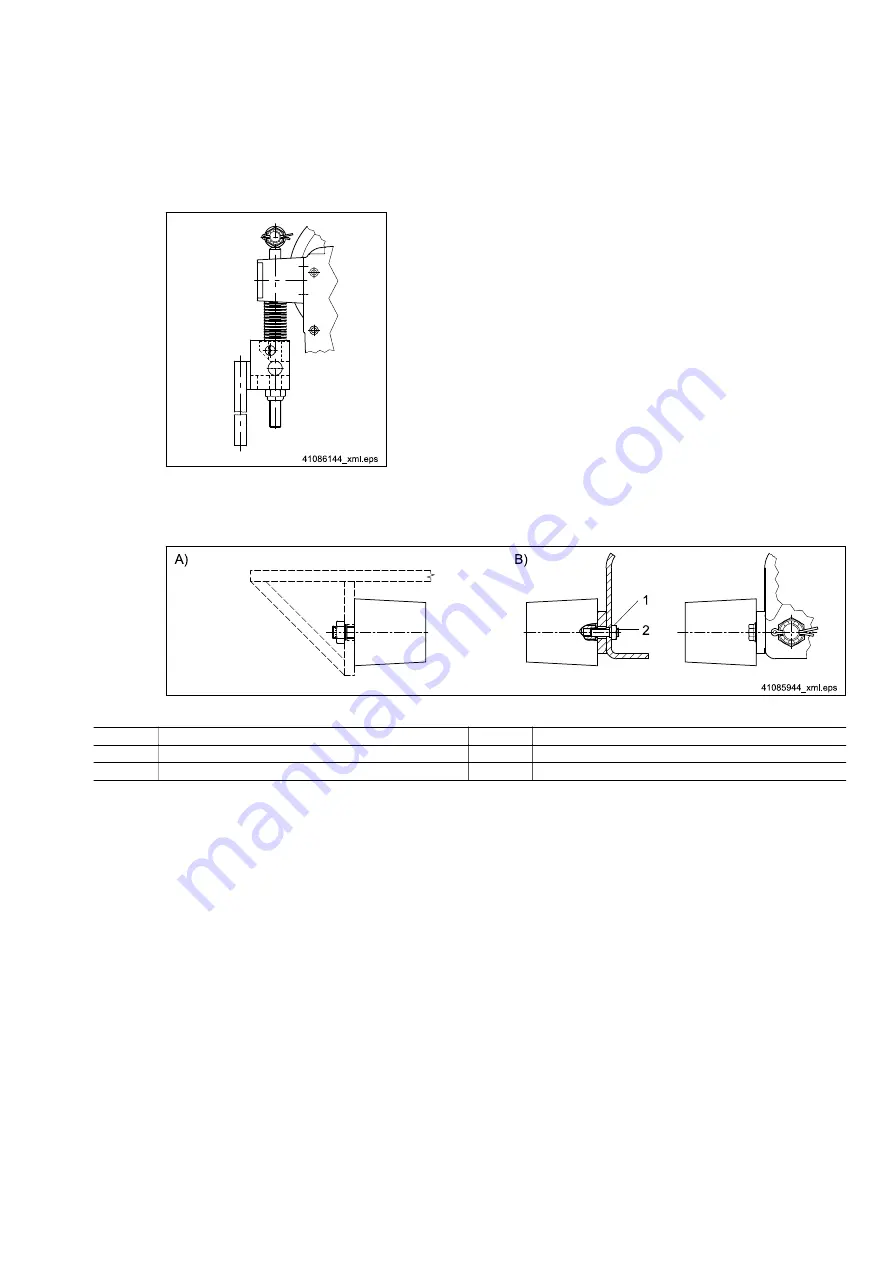

4.9

Buffer fitting

Fig. 9

Item

Designation

Item

Designation

A)

Buffer fitted to steelwork, buffered against flat steel

1

M12 set nut

B)

Buffer fitted to the trolley via flat steel

2

Threaded pin

Tab. 15

Bore holes are provided on the end surfaces of the trolley side cheeks to attach a rail for the buffer fitting. Various

types of buffer or different buffer sizes can be bolted to the middle of this rail, see also "Cellular foam buffer tech‐

nical data" document

The buffer must be attached to a trolley for travel on curved tracks on the opposite side to that of the curve travel

guide arm. A fitted buffer may collide with the track when the trolley travels through a gradient radius. In this case,

we recommend fitting the buffer to the end of the track as a stationary buffer. The impact with the stationary buffer

is then absorbed via the rail section on the trolley.

214

39

5 44/120

914

21

Summary of Contents for DRF 200

Page 51: ...214 395 44 120914 51...