13)

Insert the handwheel on stem nut and lock with the help of handwheel lock nut.

refer figure 2 .

14)

Operate the valve for open and close properly .

15)

Tighten the nut body to bonnet fully.

Note :-

1)

Tighten the body stud properly to avoid any joint leak from body to bonnet refer cause no 8

2)

Gland packing are provided to avoid to leakage trough the stem . When leakage is detected

in from the gland area while the valve is being in services, the gland should immediately

retightened tighten the gland slowly and gradually until the leakage stops. While rotating the

valve handwheel do not over tighten the packing . Even through valve are provided with back

seating feature, its not recommended to change the packing with line pressure.

3)

Use two spanners to tighten the joint in sequence as shown .

10.0 Flow Direction

Verify that the direction of the flow in the line corresponds to the arrow indicated on the valve

body . However standard valves are bidirectional.

11.0 DO’s and DONT’S

Do’s

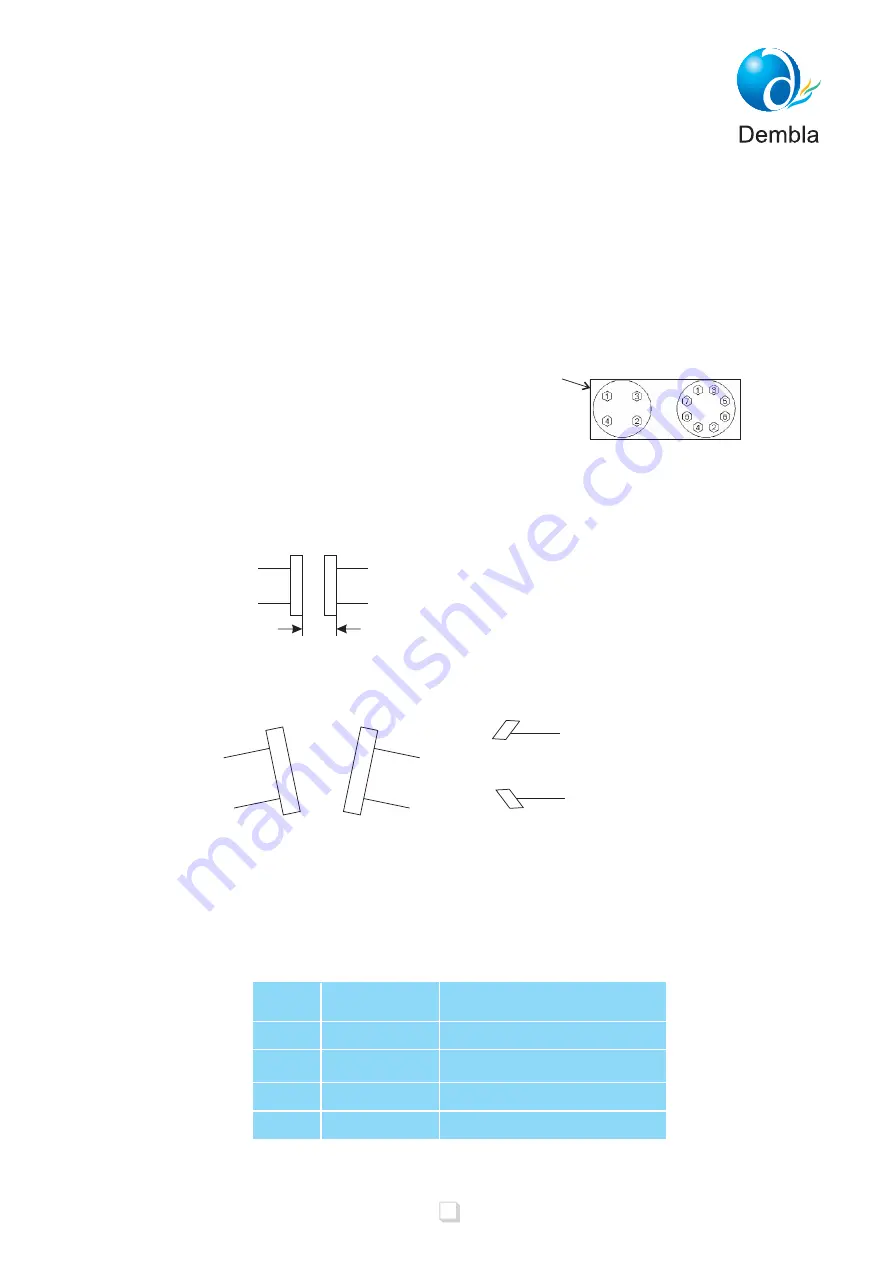

A) Pipe Work

Parallel

B) Use the valve within pressure & temperature limits.

DON'T’S

A) Pipe Work

B) Do not use the valve for the higher pressure & temperature than maximum

limits

12.0Recommended Spares

Each body -bonnet assembly is assigned with serial number, which can be found on the valve

flange OD . Ordering spares please do not miss to the valve sr. no. Prefix V-12345.........

It is recommended to stock the following part as spor are fcommission and routine service.

6

Part Name

Sr. No.

Recommended Quantity

Seat

Body Gasket

Hinge Pin

Seat Ring

One for Every ten Identical

One for Every ten Identical

One for Every ten Identical

Two for Every ten Identical

1

2

3

4