Page 18

TB20061

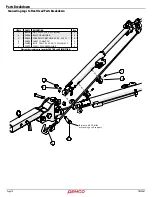

ITEM #

PART #

DESCRIPTION

Qty

KKLB

Excalibar 3 Light Bar (complete)

1.

01772

Nylon Security Strap with hooks & tightener

2

2.

01857

Left Tail/ Brake and Signal Light w/Lenses

1

3.

01773

Brown Jumper Wire

1

4.

01886

Wire Holder (metal)

4

5.

02385

Light Bar Framework

1

6.

02386

Adjustable Light Bracket

2

7.

01856

Right Tail/ Brake and Signal Light w/Lenses

1

8.

02772

1/4”-20UNC Nylon Insert Locknut

10

9.

00092

1/4”-20UNC x 1/2” Hex Head Bolt

6

10.

01777

Light Bar “Z” Bracket

2

11.

01778

3” Suction Cup w/Bolt (#13)

4

12.

02198

Light Bar Wiring Harness (new style)

1

13.

00068

1/4”-20UNC x 3/4” Hex Head Bolt

4

14.

01911

Large Red Lens

-

15.

01912

Small Red Lens

-

16.

01890

Clear Lens

-

Please order replacement parts by PART NO. and DESCRIPTION.

TESTING LIGHTS BEFORE USE

1.

With headlights in

“ON”

position, the tail lights and the

clearance lights should be lighted.

2.

Start engine and have someone depress brake pedal.

Brake lights of the light bar and towing vehicle should

come

“on”

and

“off”

simultaneously with each applica-

tion.

3.

Turn left turn signal on. Left turn light of light bar and

towing vehicle should flash simultaneously. Should

the turn signal lights of the light bar function opposite

to those of the towing vehicle, it is probable that the

YELLOW

and

GREEN

wires have been reversed. Check

the plug connections to make sure wire colors are not

crossed at any point. If plug connection is incorrect,

correct problem by reversing yellow and green wire

connection on the towing vehicle.

COLOR CODE FOR WIRING HARNESS

WHITE

Ground

BROWN

Tail Lights, License Plate Lights,

Light Cluster Bar & Clearance Lights

YELLOW

Left Turn and Stop

GREEN

Right Turn and Stop

1

1

2

1

1

6

7

8

8

8

9

9

9

8

12

13

13

11

11

8

16

15

14

9

8

4

4

3

5

10

NOTE:

The wires to the optional light bar

should be run along the car and fastened

so as not to damage the finish of the towed

vehicle.

Tow Bar Options

PARTS LIST

Light Bar

Summary of Contents for Excalibar 3

Page 1: ...TB20061 Rev 2 09 19 SELF ALIGNING TOW BAR Excalibar 3...

Page 19: ...TB20061 Page 19...

Page 20: ......