RD20026

Page 11

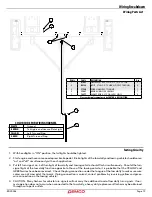

Loading Instructions

1. Make sure towing vehicle’s parking brake is fully en-

gaged. Tow dolly must be completely and properly

hooked up to the truck before loading towed vehicle.

Secure ball hitch to 2” 6,000 lb. towing vehicle ball.

Make sure that the hitch and the hitch ball are in good

condition and not rusted, loose or stripped. Both the

hitch and the hitch ball must be securely attached to

the towing vehicle. Make sure hitch is locked down and

coupler is secure. Crisscross safety chains under tongue

and secure to towing vehicle. Connect tow dolly wire

harness to towing vehicle and make sure lights operate

correctly. Securely fasten the brake actuator cable S-hook

in a straight connection to the towing vehicle. Keep the

cable connection at the towing vehicle as centered as

possible (allow some slack for turning).

Read these instructions completely before hooking, unhooking or using the

tow dolly. Be sure all loading and unloading takes place on a level surface.

2. To release tie down strap for loading, remove safety

pin and unroll straps by grasping ratchet handle pawl

(A) and ratchet handle (B) at the same time and push

down. Unroll strap enough to remove strap hooks and

lay on the ground in front of winches.

3. Before loading (and unloading) towed vehicle, make sure

platform and towed vehicle are in straight alignment.

Tow dolly must be completely and properly hooked up

to the towing vehicle. Towing vehicle must be at least

1,000 lbs. heavier than the tow dolly and towed vehicle

combined. Grasp bed release handle on tongue and

pull toward coupler. This releases the tilt bed.

Summary of Contents for Kar Kaddy X

Page 1: ...RD20026 Rev 6 08 20 TOW DOLLY Kar Kaddy X...

Page 28: ......