Installation 5

0020219190_00 Installation and maintenance instructions

13

▶

Check whether the volume of the installed expansion

vessel is sufficient for the heating system.

Conditions

: The volume of the installed expansion vessel is insufficient

▶

Install an additional expansion vessel, connected as

close to the product as possible, in the heating return.

Conditions

: External expansion vessel installed

▶

Install a non-return valve in the product outlet (heating

flow) or decommission the internal expansion vessel in

order to prevent the warm start function from being in-

creasingly activated due to backflow.

▶

Install a tundish with siphon for the condensate discharge

and the exhaust pipe on the expansion relief valve. Lay

as short a drain line as possible, at a downward gradient

away from the tundish.

▶

Insulate bare pipes exposed to environmental influences

to protect them from frost using suitable insulating mater-

ial.

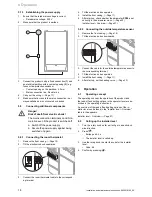

5.2

Installing the gas connection and heating

flow/return

2

3

1

1.

Install the gas line on the gas connection

(2)

without

tension.

2.

Purge the gas line before start-up.

3.

Install the heating flow

(3)

and the heating return

(1)

in

accordance with the relevant standards.

4.

Check all connections for leaks.

5.3

Installing the hot and cold water connection

1

2

▶

Install the cold water connection

(2)

and hot water con-

nection

(1)

in accordance with the relevant standards.

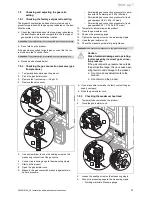

5.4

Filling the siphon and connecting the

condensate discharge pipe

Danger!

Risk of death from escaping flue gases!

The siphon's condensate drain pipework

must not be connected to waste-water piping

because, otherwise, the internal condensate

siphon may be drained fully and flue gas may

escape.

▶

Do not connect the condensate drain

pipework tightly to the waste-water pip-

ing.

1

A

C

B

D

50 ml

▶

Only use pipes which have been manufactured from

acid-resistant material (e.g. plastic) for the condensate

drain pipework.

▶

Leave an installation space of at least 240 mm beneath

the condensate siphon.

▶

Loosen the lower section of the siphon

(1)

from the con-

densate siphon.

▶

Fill the lower section of the siphon with 50 ml water.

▶

Secure the condensate discharge pipe to the lower sec-

tion of the siphon.

▶

Re-fit the lower section of the siphon onto the condens-

ate siphon.

▶

Suspend the condensate discharge pipe above the prein-

stalled tundish.

5.5

Connecting the discharge pipe to the

expansion relief valve on the product

1.

Install the supplied discharge pipe for the expansion

relief valve so that it does not interfere with the removal

and fitting of the siphon trap.

1

2.

Install the discharge pipe

(1)

as shown.