11

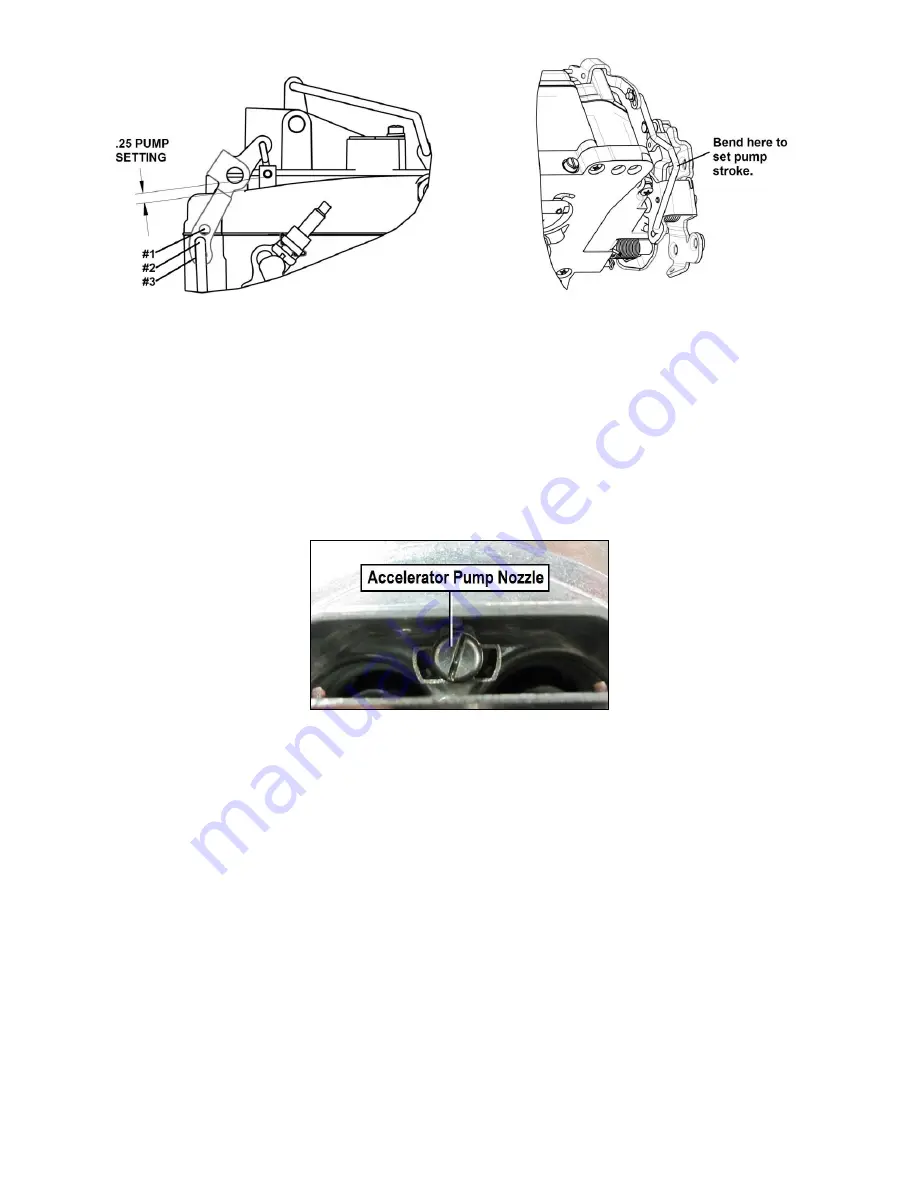

Figure 15

Figure 16

The accelerator pump stroke is set at the curb idle position to the dimensions show (Fig. 15). If you are experiencing a

stumble or hesitation on initial acceleration, it is possible that more or less fuel is needed for your particular application.

The connecting rod is positioned in the center hole #2 from the factory. A faster discharge rate is possible if the

connecting rod is relocated to hole #1. A slower discharge rate is possible using hole #3. This requires the rod to be

adjusted to reset the pump stroke (Fig. 16) to the dimension shown in Figure 15.

If after adjusting the accelerator pump stroke, a stumble or hesitation is still being experienced, it may be necessary to

change the accelerator pump nozzle. Located under the choke flap, the accelerator pump nozzle has two calibrated holes

which discharge the fuel into the venturii. The

Street Demo

n™

comes with a .031

” discharge nozzle from the factory. If

more fuel is needed, a larger discharge nozzle can be used. If less fuel is needed, a smaller discharge nozzle may be

used.

Larger camshafts, bigger cubic inch engines or “Air Gap” style manifolds may require a large squirter.

Figure 17

To remove, the accelerator pump nozzle, use a flat head screwdriver to remove the screw from the accelerator pump

discharge nozzle (Fig. 17). Using a pair of needle nose pliers, the discharge nozzle and screw can be removed from the

choke tower area. There are two gaskets used, one under the screw head and the other under the discharge nozzle. Use

extreme caution so the gasket or nozzle is not dropped into the venturii. Re-assemble in the reverse order of removal.

Main Metering Tuning

Theory of Operation

Unlike a traditional Demon carburetor, the

Street Demon

™

carburetor uses step-up pistons and metering rods for

enrichment. The metering rods protrude through the primary metering jets restricting the amount of fuel flow available.

The metering rods have two steps that are used to restrict fuel flow under various driving conditions. Manifold vacuum is

routed to the step-up piston and that vacuum works to overcome the step-up spring pressure to hold the piston in the

bottom of its bore.

Under a heavy engine load such as acceleration, the engine needs more fuel to operate properly. The extra fuel needed

by the engine is provided by the metering rods, step-up piston springs and step-up pistons. Under a heavy load condition,

there is not enough vacuum available to overcome the step-up spring pressure, therefore the piston rises in its bore and

in-turn raises the metering rod. When the rod is up, the smaller step or rich step of the rod is in the main jet orifice allowing

the extra fuel needed to pass or richen the air/fuel mixture so a desirable air/fuel ratio is maintained.