13

Steady State Cruise Tuning

Earlier, the theory of how the main metering system works was explained. During steady state cruising, there is enough

vacuum to overcome the step-up spring tension so the rod is in the down position and the lean step is in the jet. It is best

to drive the vehicle at a steady state and record the AFR or vacuum gauge reading in 10 MPH increments. Once you have

the readings, you can then determine if the engine is running rich or lean. For steady state cruising, you should target an

AFR of 13.5 to 1.

Part Throttle Acceleration Tuning (25% to 75% throttle)

During part throttle acceleration, vacuum in the engine drops and is no longer able to overcome the spring tension and the

step-up piston will rise as will the metering rod. At this point, the rich step of the metering rod will be in the jet. Have a

helper record the AFR or vacuum gauge reading during part throttle acceleration. For part throttle acceleration, you should

target and AFR of 12.5 to 1.

Remember if using a vacuum gauge, you are tuning to achieve the highest vacuum reading. At first, it may be a guess

whether it is too rich or too lean. Once you make a change, you will be able to tell by the new vacuum reading if you went

the wrong way or not.

Choosing the Correct Metering Rod and Step-Up Springs

(See next page for instructions on changing rods, springs and jets)

Once you have the readings from the steady state cruising and part throttle acceleration, you can now choose the proper

metering rod. For example; your carburetor currently has a metering rod with a .060” lean step and a .052 rich step.

During testing it is determined that during steady state cruising the engine is a little lean and during part throttle

acceleration, the engine is also a little lean. A metering rod with a lean step of .058” and a rich step of .050 can be used to

richen both of these areas up.

Remember from the theory of operation, the steps in the metering rod go into the jet orifice essentially restricting fuel flow.

So to richen the mixture, a smaller rod step is needed to allow more fuel to pass through the jet and to lean the mixture a

larger rod step is needed to restrict the fuel passing through the jet.

If the desired result cannot be achieved by changing metering rods, a larger or smaller jet can then be used to richen or

lean the mixture in combination with the metering rods.

If during part throttle testing, an issue such as a stumble or hesitation is encountered that goes away upon further throttle

opening. The engine may be experiencing a lean condition. It may be possible to correct the lean condition by going to a

stronger step-up spring.

Step up springs are color coated and are rated by inches of vacuum of “Hg. The bigger the vacuum number, the heavier

the spring is. For example; a spring with a rating of 8”Hg means that it takes 8 inches of vacuum or more to keep the

spring from raising the step-

up piston. A spring with a rating of 3”Hg only takes 3 inches of vacuum to keep it from raising

the step-up piston so it is a weaker spring. A heavier spring will allow the piston to rise in its bore sooner, therefore

placing the rich step of the metering rod into the jet orifice eliminating the lean spot. The chart below outlines the available

step-up springs.

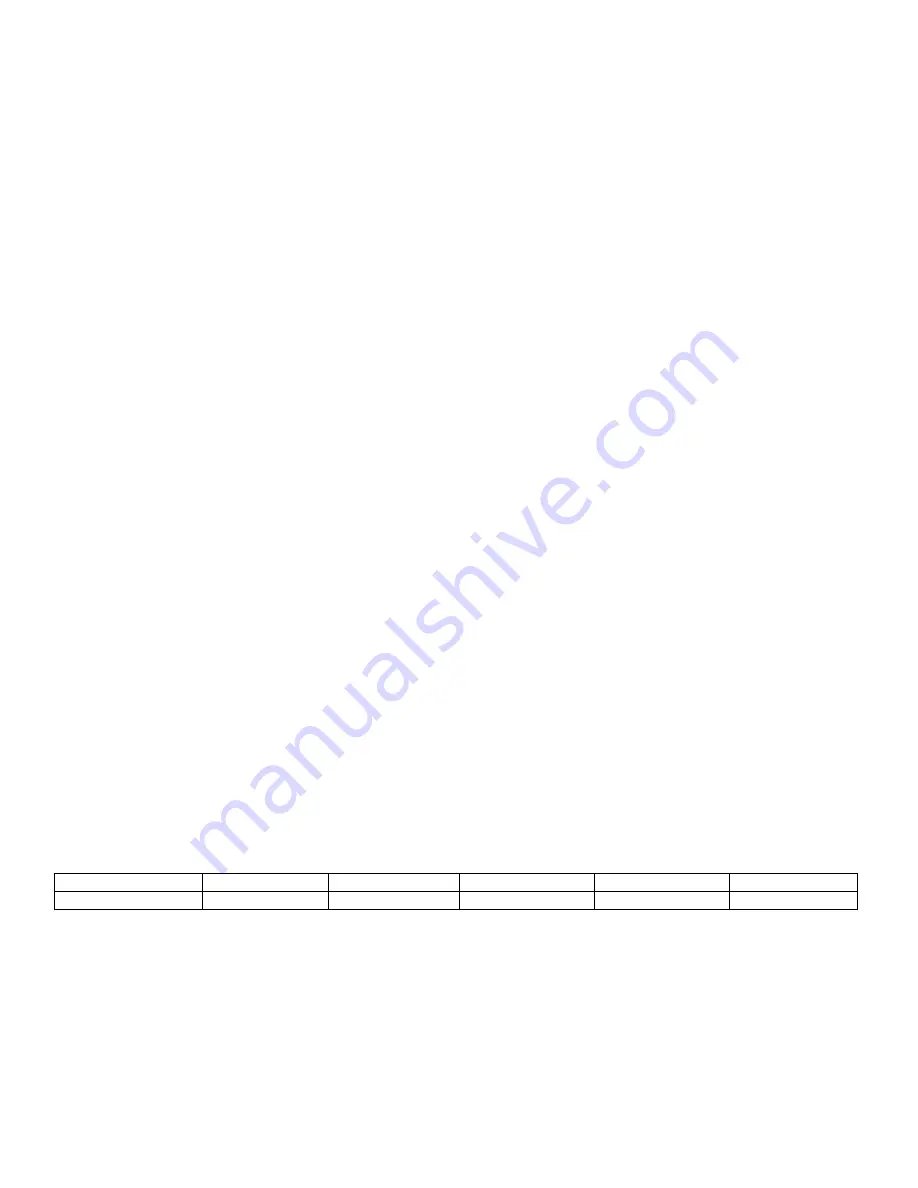

Spring Color

Blue

Yellow

Orange

Green

Silver

Rating in “Hg

3”Hg

4”Hg

5”Hg

6”Hg

8”Hg

Wide Open Throttle Tuning

(See next page for instructions on changing rods, springs and jets)

Wide open throttle (WOT) tuning is best performed after the steady state cruise and part throttle acceleration is complete.

WOT tuning is best performed using a dyno or at the drag strip. DO NOT attempt to perform wide open throttle tuning on

the street. Using a helper, AFR or vacuum gauge readings should be taken at WOT to determine if the engine is running

rich or lean. Tuning the WOT is done by changing the secondary metering jets. If the engine is to lean, go up a couple of

steps in the secondary metering jets, if it is too rich; go down a couple of sizes in the secondary metering jets. It is not

recommended to go more than two sizes at a time so that it is easier to monitor the changes.