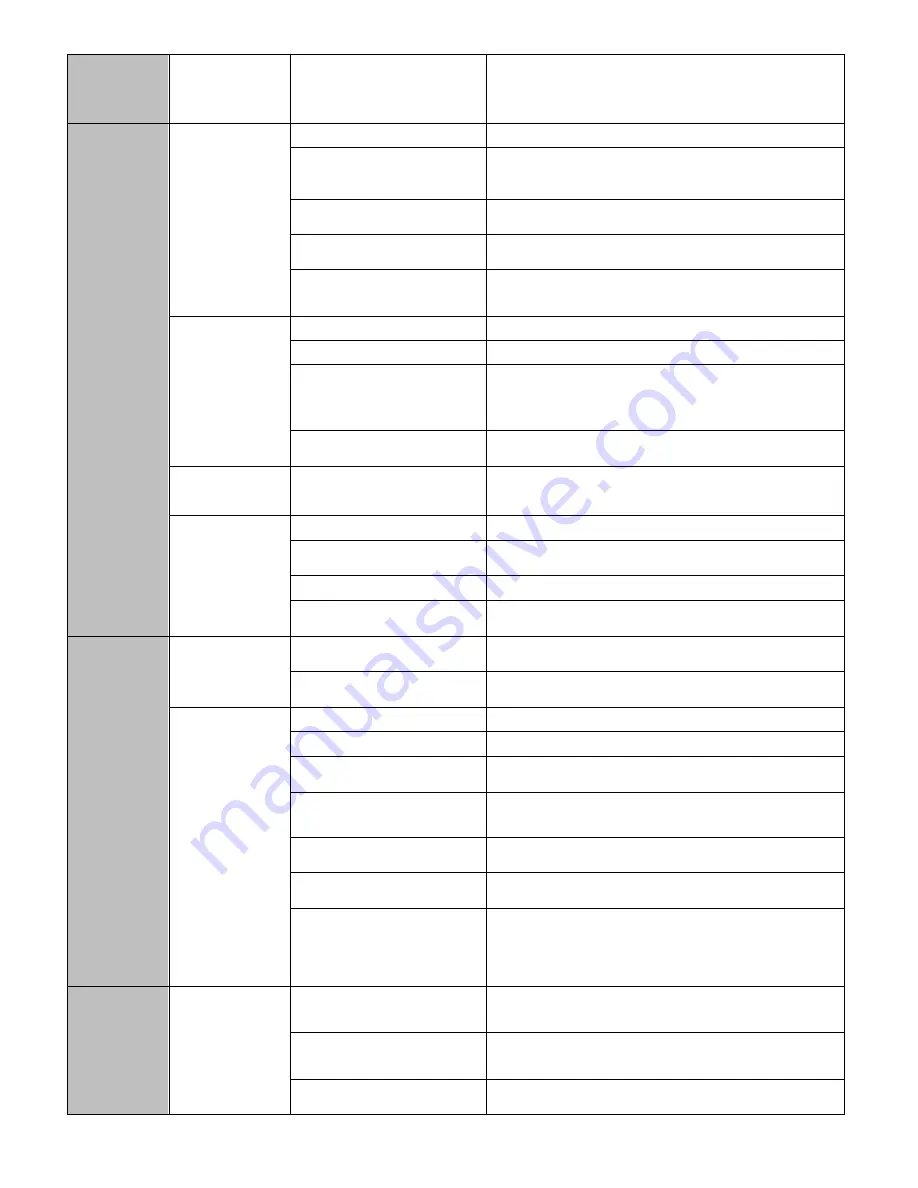

17

Engine starts, then

races for a few

seconds and then

dies every time.

1) Big vacuum leak somewhere.

1) Correct the vacuum leak. Make sure you haven't forgotten to

hook up a hose somewhere. Base gasket may be wrong one or

on wrong.

Warm Starting

Warm Starting

(Cont.)

Engine cranks but

will not start.

1) Carburetor flooding.

1) Fix cause of flooding.

2) Choke is closed when engine

is hot.

2) Find & fix cause for choke staying closed. Check power and

ground, make sure power wire has a full 12v or something

jammed or bent, check choke linkage to air cleaner clearance

3) No fuel

3) Check fuel delivery volume and pressure. Look for clogged

lines, filter, or pump. Check for kinked or swollen fuel lines.

4) No air.

4) Check for clogged air filter, especially after driving through

muddy or dusty area.

5) Too much air.

5) Look for big vacuum leak, such as broken hose, blown

gasket, bad power brake diaphragm, bad PCV valve (Rough

Idle).

Engine starts, then

dies within a few

seconds.

1) Choke is staying closed

1) Diagnose and fix choke problem.

2) Carburetor flooding.

2) Fix cause of flooding.

3) Venting system failure.

3) Check out entire fuel system venting system, including the

vent valve on the carb, the charcoal canister, all hoses & check

valves in the system, and any solenoids that trigger the vent

system to operate.

4) Step-Up Piston up in bore

4) Remove step-up piston and fix sticking issue or use a lighter

step-up spring

Engine starts,

races for a few

seconds, then dies.

1) Big vacuum leak somewhere.

1) Find the vacuum leak & fix it. Also look for wrong base gasket

or one that is installed wrong. If engine has been spitting back, it

may have blown out the base gasket or a gasket in the carb.

Engine starts OK,

but then gets real

rough. Lots of black

smoke.

1) Slow flooding.

1) Fix cause of flooding.

2) Step-Up Piston up in bore

2) Remove step-up piston and fix sticking issue or use a lighter

step-up spring

3) Venting system problem.

3) Check entire venting system & repair.

4) Fuel dripping from secondary

nozzles

4) Tighten secondary air door ¼ turn counterclockwise

Cold Engine

Drivability

Condition

Engine stalls when

transmission is put

into gear.

1) Fast idle RPM incorrect (too

slow)

1) Speed up the fast idle to factory specs.

2) Engine running too lean due to

vacuum leak or dirty jet.

2) Check for vacuum leak. Flow test carb to check jetting.

Hesitation, stalling,

stumbling, dead

spot during

acceleration:

Backfiring or spit

back through carb.

1) Vacuum leak.

1) Check for vacuum leak & repair.

2) Ignition timing retarded too far.

2) Reset timing.

3) Accelerator pump nozzle has

dirt in it.

3) Clean out the nozzle tip.

4) Accelerator pump cup swollen

up from contact with bad gas or

chemicals.

4) Replace the pump cup.

5) Secondary air door opening

too quickly

5) Adjust air door

6) Vacuum hoses hooked up

wrong.

6) Connect up right. Be especially careful of the EGR & Dist.

connections

7) Distributor timing not

advancing properly (worn breaker

plate, worn shaft, pin hole in

distributor diaphragm, cracked

hose, etc.)

7) Check distributor and all related systems carefully. Replace

defective parts.

Warm Engine

Hesitation under

light throttle: dead

spot & stumble.

1) Vacuum leak somewhere, or

hose off or hooked to wrong

vacuum port.

1) Inspect hoses. Route and lead the hoses correctly. Look for

leaks caused by the wrong base gasket or if it was installed

upside down.

2) Accelerator pump problems.

2) Inspect and adjust pump stroke, pump plunger, discharge

nozzles and check valves. Inspect the accelerator pump, look

for swollen pump cup.

3) Float level set very low.

3) Set to factory specs. Factory setting, with air horn upside

down, is 1.01”+/- .015” from the cast surface to bottom of float.