Multi

MAXX

HD

Technical Description

PR-2007-0350-GB • Subject to modifications • R2-04/2016

15

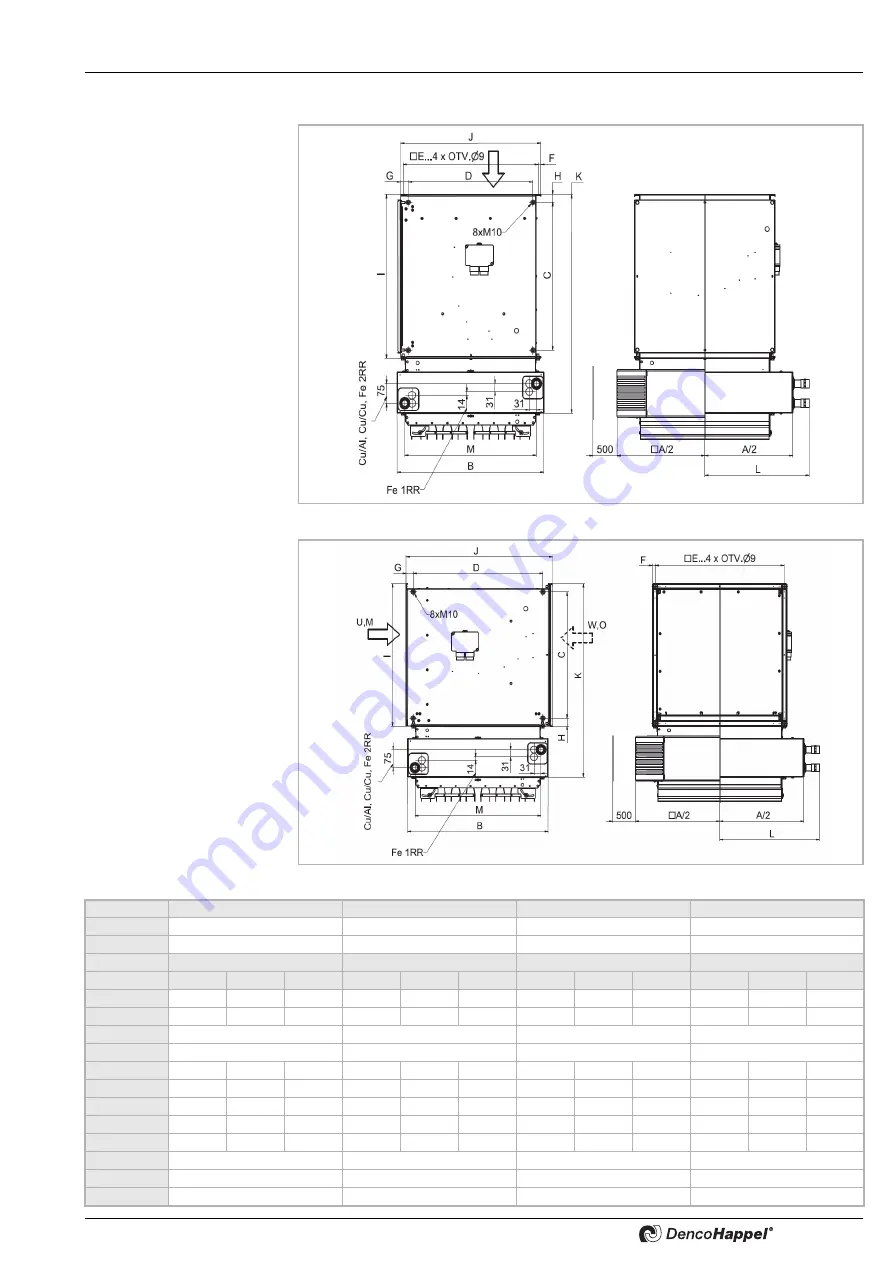

5.2.2 Ceiling installation

Unit designation

Y, R

Fig. 5-6

Unit designation

U, M, W, O

Fig. 5-7

Size

1

2

3

4

A

642

738

866

1026

B

532

628

756

916

Model

Model

Model

Model

Y, R

U, M, W, O V, N, X, P

Y, R

U, M, W, O V, N, X, P

Y, R

U, M, W, O V, N, X, P

Y, R

U, M, W, O V, N, X, P

C

473

427

427

569

523

523

697

651

651

857

811

811

D

427

473

473

523

569

569

651

697

697

811

857

857

E

470

566

694

854

F

12

12

12

12

G

32

31

–

32

31

–

32

31

–

32

31

–

H

31

32

34

31

32

34

31

32

34

31

32

34

I

535

493

493

631

589

589

759

717

717

919

877

877

J

493

547

494

589

643

590

717

771

718

877

931

878

K

745

703

703

841

799

799

969

927

927

1129

1087

1087

L

(Cu/Al, Cu/Cu)

399

447

511

591

L

(Fe)

361

409

473

553

M

457

553

681

841