-

29

-

© by DENQBAR GmbH

www.denqbar.com

START-UP

Checking at the engine before start-up

Assure that the machine is assembled completely and according to the instructions.

Remove all other objects from the operational area.

Check the machine before every use concerning damages and be sure that all screws are tightened

correctly and protective covers are fixed.

The compactor will be delivered without any gasoline or oil.

Before the start-up please fill in the oil for the engine, exciter and the gasoline.

Oil level check at the engine:

If the oil level gauge shows no oil level if it is screwed in, please fill in oil SAE 10W40 till the edge of

the oil-filler neck.

If you check the oil level the engine has to be levelled out horizontally.

Oil level check at the exciter (only type DQ-0139):

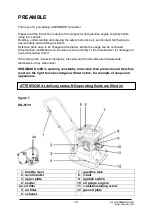

(Fig. 1, number 4)

:

Before starting the exciter has to be checked on correct oil level.

The compactor has to be horizontally.

The oil level has to reach until the beginning of the oil-filler neck (Fig. 1, number 4a). Fill in the engine

oil SAE 10W40 through the opening until the correct level is reached (use a funnel).

Air filter

(Fig. 1, number 5)

:

Check if the air filter application is clean and in well condition. If necessary clean the applications or

change them.

Gasoline:

Each normal petrol (unleaded petrol) with octane index (ROZ) of 95 can be used.

Never use a mix of oil and petrol or dirty petrol.

Avoid infiltration of the gasoline tank by water, dust or dirt.

It is not recommended to use alternative for gasoline, because this can cause damage of parts of the

gasoline system.

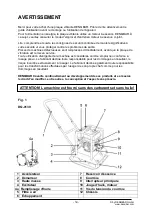

OPERATION

1. Starting preparation

Check following points before each start:

- gasoline level

– the tank should be filled at least half-full

- level of engine oil / level of exciter oil

- closeness of gasoline pipes

- close hub of each bolted connection outside

- put the crank of rev adjustment into engine idle