10

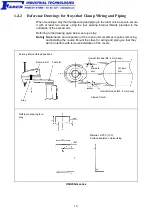

1.2.3

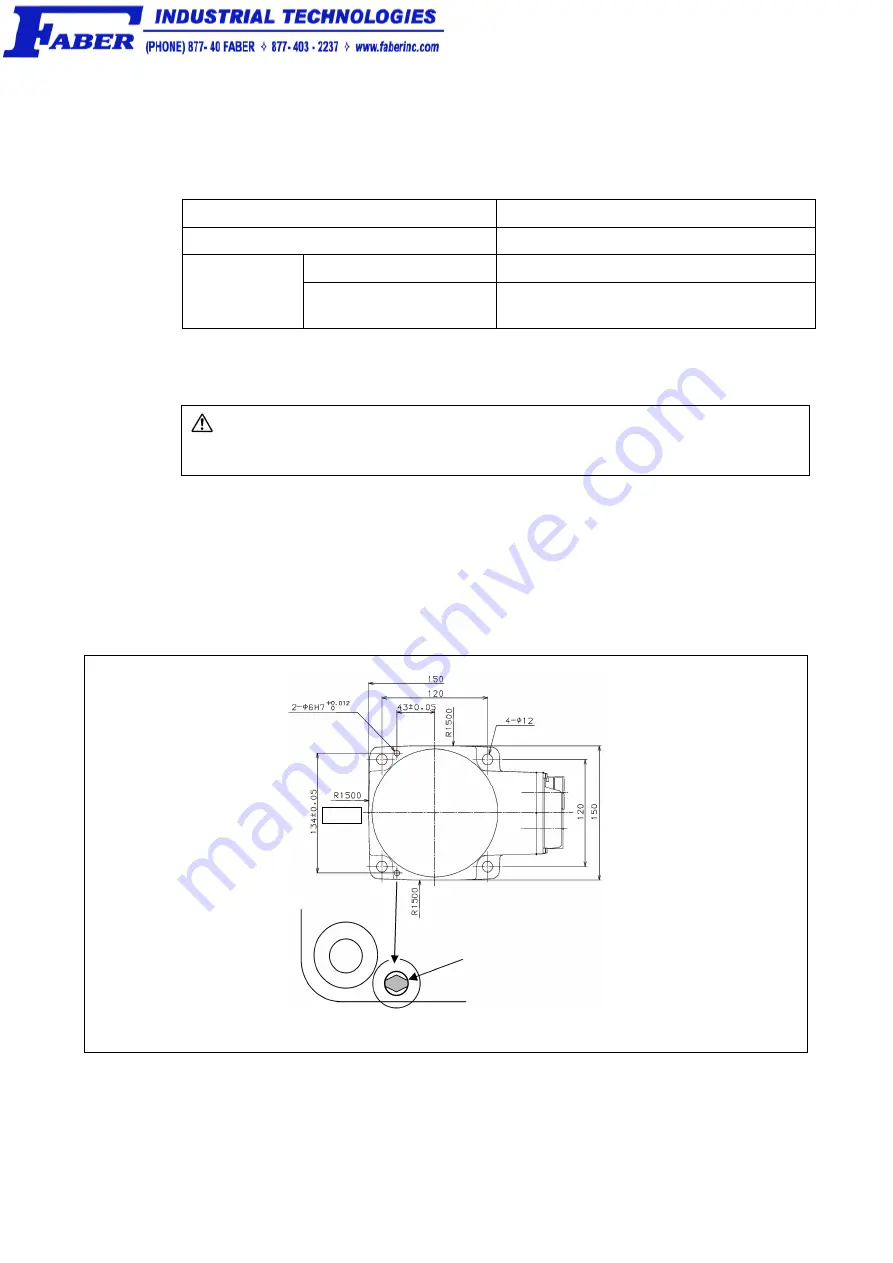

Securing the Robot Unit

(1) According to the dimensions specified in the figure below, drill four robot fixing holes

and two dowel pin holes in the robot mount where the robot unit is to be anchored.

Drilling in the robot mount

Drilling in the robot mount

For HS/HSS-G series

Four robot fixing holes

M10 bolt holes, a minimum of 20 mm deep

For diamond-shaped pin

4H7 dia. hole a minimum of 10 mm deep

Two holes for

dowel pins

For internally-threaded

positioning pin

6H7 dia. hole, a minimum of 10 mm deep

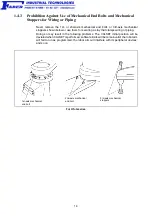

(2) Drive a diamond-shaped pin into the hole (HS/HSS-G: 4H7 dia.) so that the pin

becomes oriented as shown below.

(3) Drive an internally-threaded positioning pin into the hole (HS/HSS-G: 6H7 dia.).

Caution: Never skip this step. These dowel pins can minimize the risk of

misalignment that could be caused by replacement of the robot unit

during maintenance or due to vibration.

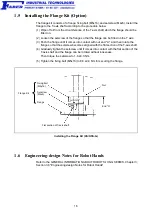

(4) Put the robot unit on the robot mount, following the transport instructions given in

Section 1.2.1 "Transporting the Floor-Mount Type" or Section 1.2.2 "Transporting the

Overhead-Mount Type."

(5) Secure the robot unit with four bolts and plain washers.

Fixing bolts: M10 x 30 mm, JIS strength class: 12.9 (For HS/HSS-G series)

Tightening torque: 70

14 Nm (For HS/HSS-G series)

(For HS/HSS-G series)

Bolt Positions for Securing the Robot Unit

Front

Diamond-shaped pin

Reference hole