61

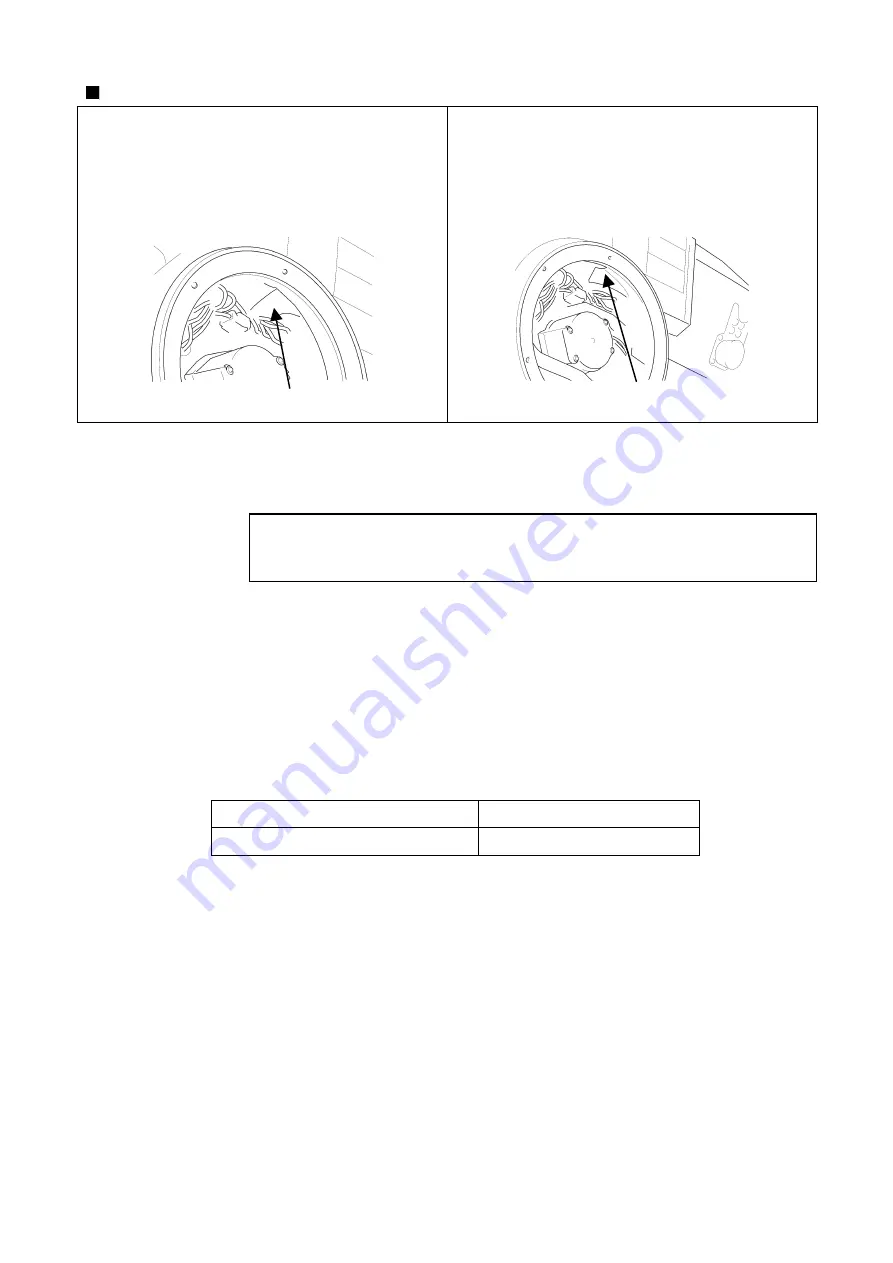

Checking the 4th-axis position for VS-6556

The internal wiring is visible in the normal condition

as below.

When the 4th-axis section is rotated from where it is

as shown on the left, the internal wiring is caught in

the crank and becomes invisible in the left figure.

(The figure below shows the crank at around 250

°

.)

Internal wiring

Cast crank

(4) When the 4th-axis section is not at the normal position, manually move it to a

designated position.

Preparation before carrying out CALSET is finished now.

NOTE: If the step [2.4.2] is omitted, the 4th-axis CALSET position may be

mistaken by one rotation (360

°

). The internal wiring may be caught in

the crank and broken in such a case.

2.4.3 Preparation

for

CALSET

The VS-G series has no mechanical stop on the 4th and 6th axes.

Mechanical Stops on Axes (VS-G)

On the 1st to 3rd and 5th axes

On the 4th and 6th axes

Mechanical stops provided

No mechanical stops

Press each of the 1st, 2nd, 3rd, and 5th axes manually against the associated

mechanical stop and get the actual position.

Since the 4th and 6th axes have no mechanical stop, you need to mount a CALSET jig

to set a temporary mechanical end for CALSET. Then press the 4th and 6th axes

against those mechanical ends and get those positions. When CALSETing the 6th axis,

you need to press also the 5th axis against the mechanical stop since CALSETing

requires the positional relationship between the 5th and 6th axes.

Summary of Contents for VS-6556G

Page 1: ...ROBOT Vertical articulated VS G SERIES INSTALLATION MAINTENANCE GUIDE...

Page 6: ......

Page 67: ...49 Reference Drawing of Part A Material A2017 T4...

Page 68: ...50 Reference Drawing of Part B Material A2017 T4 Reference Drawing of Part C Material A2017 T4...

Page 71: ...53 Reference Drawing of Stay for 3rd axis Mechanical End VS6556G Material A2017 T4...

Page 118: ......

Page 120: ......