51

8-9 OIL IS MIXED IN DELIVERED AIR (oil not fully separated)

The machine is not installed on level

ground

…

Install it on level ground (allowable inclination is

5°forward/backward and left/right directions).

Delivered air pressure is low

Set pressure retaining valve to 0.42 to 0.7 MPa.

Compressor oil level is higher than the

upper limit

…

Confirm than the level is within the specified

range when the engine is stopped.

Drainage is larger than usual

…

Open the drain valve to extract drainage

in the oil chamber.

Filter orifice of the oil return pipe are

clogged

…

Check and clean the orifice.

Engine was started with the unloader

valve set to “RUN” position.

…

Start the engine with the unlaoder valve

set to “START” position and operate

it in a no-load condition.

Service valve(s) or start run valve

has been quickly opened after

the engine stopped

…

Do not attempt to quickly discharge it through

the air outlet valve(s) after the engine stopped.

Life of the oil separator has come to

an end

…

Replace.

8-10 OVERHEATING

Re-confirm surrounding conditions

…

Reduce suction of exhaust gas.

Cooling water is emptied or short

…

Check and replenish cooling water.

Check and replace radiator cap.

Fan belt is loosened

…

Check and retighten.

Radiator and oil cooler cores are clogged

…

Clean.

Delivery pressure is high

…

Check and repair pressure regulator valve.

Engine thermostat is abnormal

…

Check and readjust.

Summary of Contents for DIS-390ES

Page 58: ...55 10 2 Outline drawing DIS 390ES...

Page 59: ...56 DIS 390ES trailer type...

Page 60: ...57 DIS 390ES C...

Page 61: ...58 DIS 390ES C trailer type...

Page 62: ...59 DIS 390ES D...

Page 63: ...60 DIS 390ES D trailer type...

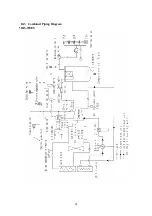

Page 64: ...61 10 3 Combined Piping Diagram DIS 390ES...

Page 65: ...62 DIS 390ES C...

Page 66: ...63 DIS 390ES D...

Page 67: ...64 10 4 Engine wiring diagram...