- 27 -

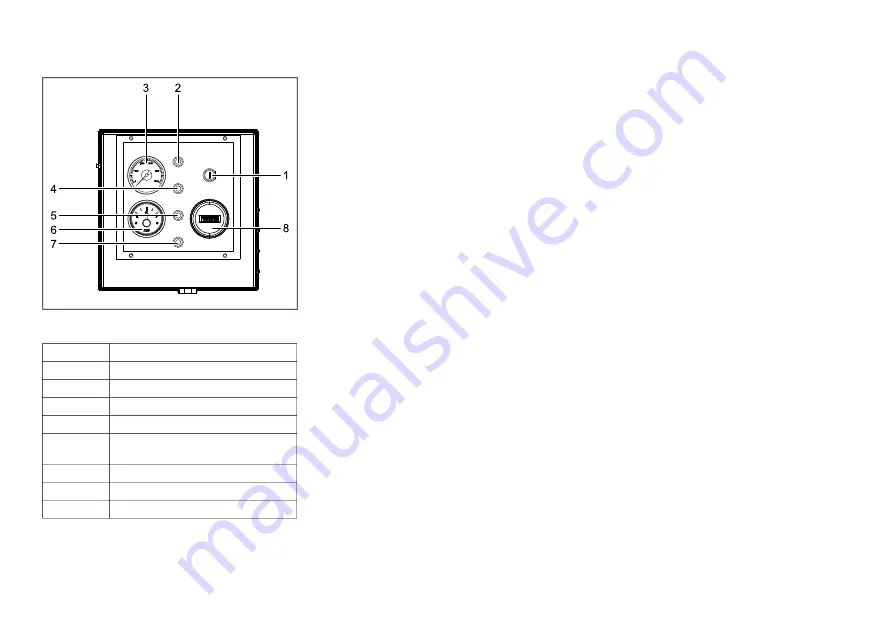

Controller Panel

CONTROL PANEL DESCRIPTION

1. The engine ignition key port (1) is used to start the

engine.

2. The fuel level low indicator (2) glows if the fuel

level in the fuel tank is low.

3. The pressure gauge (3) is used to monitor the

outlet pressure of the unit.

4. The battery malfunction indicator (4) glows if the

battery is about to fail. Some situations where this

indicator will glow are when the level of

electrolyte is low, the battery is short, the battery

begins gassing, the battery is overheating etc.

5. The temperature switch at the compressor outlet

port continuously monitors the outlet temperature.

If the outlet temperature exceeds the limiting

conditions (see section Technical specifications,

limitation ), the compressor outlet temperature

high indicator (5) begins to glow.

6. The Fuel gauge (6) helps monitoring the quantity

of fuel filled into the fuel tank. Do not overfill the

fuel tank. Fill fuel within the limits represented on

the fuel gauge (6).

7. The temperature switch at the outlet of the oil

cooler continuously monitors the oil temperature.

If it is higher than the permissible limits, the Oil

temperature high indicator (7) begins to glows.

8. The machine running hours can be tracked on the

running hours meter (8). It can be used to track

hours between required service activities.

STARTING/STOPPING

SAFETY PRECAUTION

1. Before starting the machine, make sure that the

fuel tank is full.

PROCEDURE

1. Insert the ignition key into the ignition key port

(1). Twist the ignition key in the clockwise

direction to start the engine.

2. Run the engine for a few minutes at no-load to

warm up.

3. To shut down the engine, twist the ignition key in

the anti-clockwise direction.

Reference Description

1

Engine ignition key port

2

Fuel level low indicator

3

Pressure gauge

4

Battery malfunction indicator

5

Compressor outlet temperature high

indicator

6

Fuel gauge

7

Oil temperature high indicator

8

Meter for running hours

Summary of Contents for DU-190

Page 1: ...8 Instruction Manual English...

Page 2: ......

Page 16: ...16 Main Parts...

Page 18: ...18 COMPRESSOR REGULATING SYSTEM...

Page 22: ...22 CONTINUOUS PNEUMATIC REGULATING SYSTEM...

Page 60: ...60 ELECTRIC SYSTEM Circuit diagram 9829 3801 10...

Page 61: ...61 Circuit diagram 9829 3801 10...

Page 62: ...62 ELECTRIC SYSTEM Wire harness 1094 3133 02...

Page 67: ......

Page 68: ......