27

7 Trouble Shooting

In the case of a malfunction, check and observe all instructions contained in

this technical documentation. If necessary, adjust equipment as needed.

Possible faults and their causes are shown below:

E

RROR

R

EASON

S

OLUTION

No air, Shut-Off valve is

closed

Open Shut-Off valve

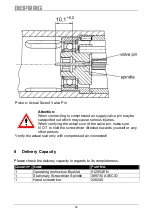

Valve pin is too short or

missing

Test valve pin length according to

picture:

Actual size of valve Pin

and replace valve pin, if necessary

Screwdriver

does not start

Piston 3804692 caught

in sleeve 3783221

Disassembly and cleansing of

parts

Clutch is not engaged

Mount clutch correctly - refer to:

Range- and exchange of clutch

spring

Air pressure too low

Minimum air pressure should be 90

PSI for maximum performance

Restriction in air hose

Remove bends or other restrictions

Hose I.D. is too small

Use required hose I.D.

Valve Pin too short

Check required length of valve pin

according to picture:

Actual Size of

Valve Pin

. If needed, exchange

valve pin.

Insufficient

Power

Vanes are worn

Exchange vanes

Screen Support or si-

lencer clogged

Clean screen support /silencer or

exchange with new one

Air pressure is too low

for required torque va-

lue

Maintain air pressure of 90 PSI

Valve Pin is too long

Check length of valve pin, either

shorten or replace valve pin (pic-

ture:

Actual Size of Valve Pin

)

Driver does not

shut-off or

ratchets

Piston 3804692 caught

in sleeve 3783221

Disassembly and cleansing of

parts

If necessary, please send tool to DEPRAG for service.

Summary of Contents for 344-340-31

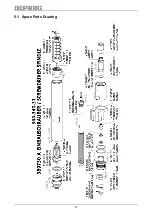

Page 17: ...17 5 1 Spare Parts Drawing ...

Page 18: ...18 ...

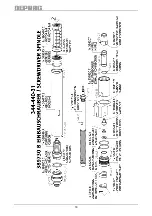

Page 19: ...19 ...

Page 20: ...20 ...

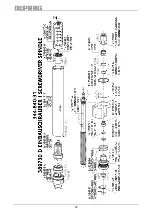

Page 21: ...21 ...

Page 22: ...22 ...

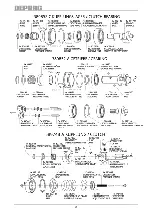

Page 23: ...23 ...

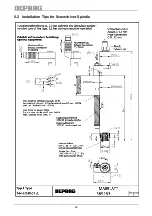

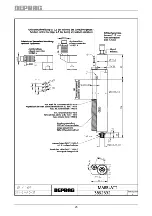

Page 24: ...24 5 2 Installation Tips for Screwdriver Spindle ...

Page 25: ...25 ...