111250-01C

For more information, visit www.desatech.com

For more information, visit www.desatech.com

21

21

FIREPLACE INSTALLATION

Continued

FIREPLACE INSTALLATION

Checking Gas Connections (Cont.)

Installing Optional Wall Mount Switch - GWMS2

Installing Optional Wireless Hand-Held Remote Control - GHRC and GHRCT(A) Series

Installing Remote Receiver

1.

Open bottom louver and locate the switch bracket on the left.

2.

Unscrew the switch bracket. Lean bracket forward so you are

able to access the back of the remote receiver.

INSTALLING OPTIONAL WIRELESS HAND-

HELD REMOTE CONTROL - (C)GHRC AND

(C)GHRCTA SERIES

NOTICE: Use only alkaline batteries (not included).

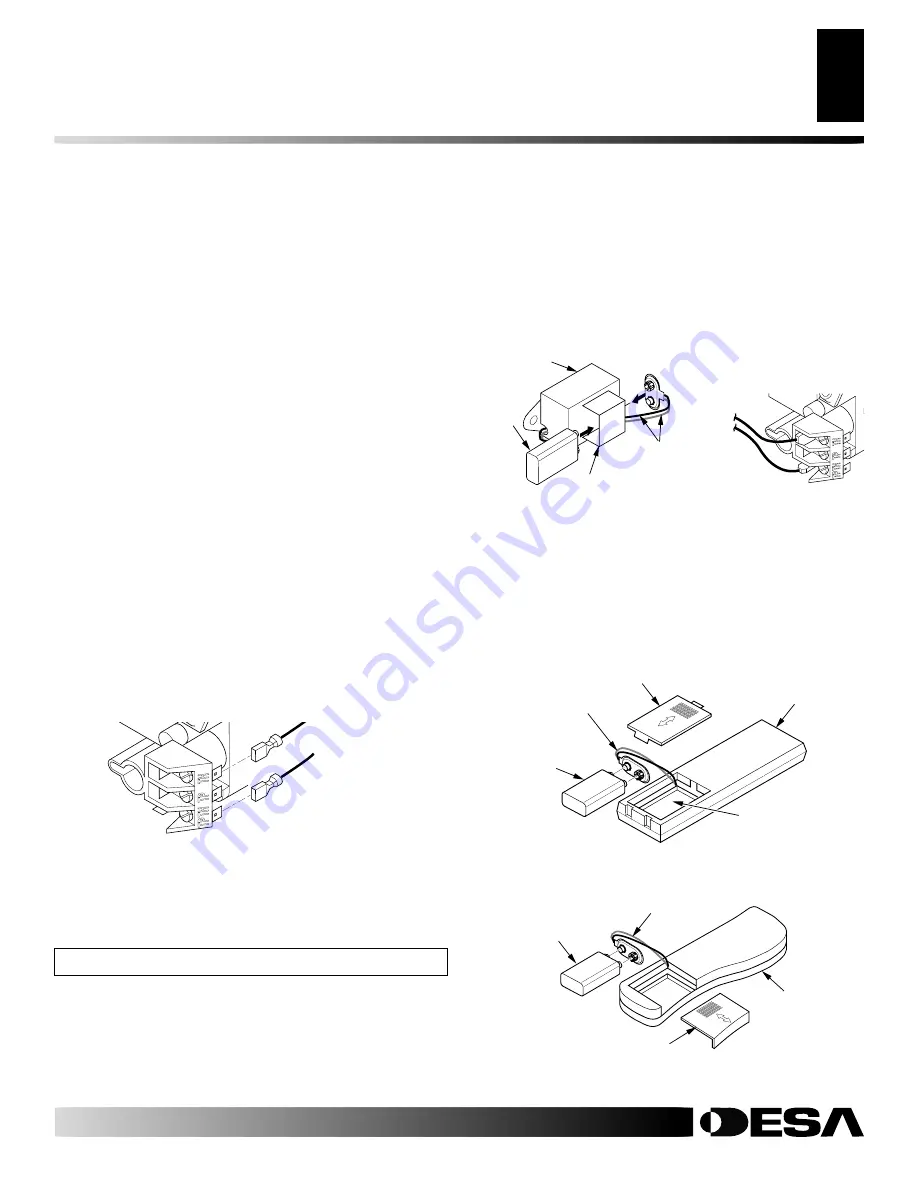

Figure 37 - Attaching Alkaline

Battery to Receiver

Figure 38 - Connecting

Remote Accessory to

Control Valve

To Optional

Remote

Accessory

9-Volt

Alkaline

Battery

Receiver

Terminal

Wires

Battery Clip

Pressure Testing Fireplace Gas Connections

1.

Open equipment shutoff valve (see Figure 33, page 20).

2.

Open propane/LP supply tank valve for propane/LP fireplace

or main gas valve located on or near gas meter for natural gas

fireplace.

3.

Make sure control knob of fireplace is in the OFF position.

4.

Check all joints from equipment shutoff valve to gas valve (see

Figure 34 for propane/LP or Figure 35 for natural gas, page 20).

Apply noncorrosive leak detection fluid to all joints. Bubbles

forming show a leak. Correct all leaks at once.

5.

Light fireplace (see

Operating Fireplace

, page 25). Check all

other internal joints for leaks.

6.

Turn off fireplace (see

To Turn Off Gas to Appliance

, page 25).

Installing 9-Volt Alkaline Battery in Hand-Held

Remote Control Unit

1.

Remove battery cover on back of remote control unit.

2.

Attach terminal wires to a 9-volt alkaline battery (not included).

Place battery into the battery housing.

3.

Replace battery cover onto remote control unit.

Figure 39 - Installing Alkaline Battery in Hand-Held Remote

Control Unit ([C]GHRC)

Battery Cover

9-Volt

Alkaline

Battery

Terminal

Wires

Remote

Control Unit

Battery

Housing

Figure 40 - Installing Battery in Hand-Held Remote Control Unit

([C]GHRCTA Series)

Remote

Control

Unit

Battery

Cover

9-Volt

Battery

Terminal

Wires

Figure 36 - Connecting Wall Swith to Control Valve

INSTALLING OPTIONAL WALL MOUNT

SWITCH - GWMS2

1.

Connect one terminal of 25 ft. wire for the wall switch to the

TPTH terminal on the valve. Connect remaining wire terminal

to the TH terminal on the valve. Make sure that the wire termi-

nals are in the positions on the unit as pictured in Figure 36. If

wires are not connected as shown the switch will not work.

2.

Route the 25 ft. wire through openings provided on the sides of

the burner system to a convenient location to mount your switch.

3.

Connect one bare wire end to each of the terminals of the

GWMS2 wall switch.

4.

Install the wall switch and cover in the wall.

3.

Locate the battery clip mounted on the back of the receiver.

Slide a 9-volt alkaline battery (not included) through the clip

(see Figure 37).

4.

Attach the terminal wires to the battery.

5.

Connect wires from receiver to TH and TPTH to control valve

(see Figure 38).

6.

Replace the switch bracket.

To Wall Switch

Accessory