STARTING AND OPERATION OF THE

FURNACE

Set both switches to position "0".

Check the setting of the ‘reset’ button of the

overheating thermostat (9) on the side of the fan

housing.

Check whether the supply voltage corresponds to the

voltage given on the rating plate, and then put the plug

into a socket.

Open the fuel tank cover and fill it up with oil or oil

mixture. The tank may be filled up to the half of the inlet

filter height (40).

WARNING:

Maintain the necessary precautions while filling up the

tank. The oil may not be spilled beyond the filter area,

and the tank may not be overfilled.

The full fuel tank should suffice for about 16 hours of

operation at maximum thermal power.

If needed, discharge water from the fuel tank and clean

the inflow filter. The ball valve (39) is located on the

side of the tank.

Open the top cover (4).

Remove the cover of the incineration chamber and take

out rings from it. Check whether the burner plate is cool

and clean, then pour about 180 ml (one small cup) of

diesel oil onto the combustion dish (22).

In order to set the oil on fire, crumple paper into a small

ball, light it up and throw it onto the incineration plate.

WARNING:

Do not light the furnace again, when the chamber or the

incineration plate is still hot!

Put the ring and cylinder back inside, place the cover of

the incineration chamber and close the top cover (4).

Wait for 5 minutes, until the incineration chamber is

initially heated.

Set both switches to position ”I”.

When the chamber is sufficiently heated, the fuel pump

and the fan will be started. Apart from this, the control

lamp informing about the operation of the pump will be

lighted. The pump will operate in cycles, therefore, the

lamp will be switched on and off once in several

dozens of seconds.

After 20-30 minutes, change the setting of switch (67)

to position ”II”. The furnace will then operate with

greater heating efficiency.

WARNING:

The fan will start its operation automatically, when the

furnace reaches an adequate temperature.

SWITCHING OFF THE OVEN

Set switch (67) in position “0”. Then the fuel pump will

stop.

After the furnace cools off (10-30 minutes) the fan will

switch off automatically. Then set switch (49) in position

”0”

Do not ever set switch (49) in position ”0” and take out

the plug from the socket before the furnace cools off

entirely.

MAINTENANCE

If the connector conduit (59) is polluted, the oil will return

to the tank in front of the device, by means of the

overflow conduit (60).

The fuel pipes must be cleaned or replaced, if they are

burnt or damaged.

Clean the furnace everyday, maximum every 10 hours of

the device’s performance.

To perform cleaning, the tank may be taken out.

Protect the inside walls of the incineration chamber from

making them dirty with soot.

Each time before storage for a longer period of time, it is

recommended to clean the furnace exactly and wipe the

incineration chamber with a cloth soaked with oil in order

to prevent it from rusting.

Clean the draught regulator and the chimney installation

twice a year.

In the case when the parts or any modifications in the

electrical system are performed willfully, the warranty for

the device will be withdrawn.

It is recommended to apply only the spare parts

recommended by the manufacturer.

The device must be subjected to regular checks and

maintenance activities performed by an authorised

maintenance employee.

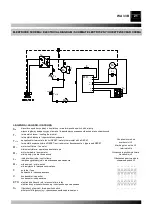

TROUBLESHOOTING

In the case of the failure of the device, the list below may help

in locating a defect. In general its removal is simple. The most

frequent problems are listed below. Digits signify the possible

reasons listed further on in chapter entitled ”Troubleshooting”.

The order of digits expresses the probability of occurrence of a

defect.

Always check

a: Voltage

b. Fuel inflow to the incineration plate

c. Chimney flue (see “Installation of the chimney flue”).

WA 33 B

7

Summary of Contents for Master WA 33 B

Page 23: ...WA 33 B WA 33 B 23 ...