www.desatech.com

115423-01A

6

CAUTIONS

1. Before servicing, disconnect the heater from

the electrical power source by removing the

electrical plug from the wall receptacle.

Note:

When certain tests require electrical power

to be applied, connect electrical power only for

the time necessary to complete the test.

2. Do not bypass safety devices except when

instructed to do so during troubleshooting

procedures.

3. If replacement parts are necessary, do not

substitute with non-factory parts (use only

factory authorized replacement parts).

4. Make sure all electrical connections are secure

and correct prior to connecting heater to a

grounded electrical power source.

ALL SYSTEMS WORKING

TOGETHER

There are three basic systems within the heater, the

heating system, air system and safety system.

A tubular heating element (A) warms the sur-

rounding air.

A fan (B) on one end of a motor (C) draws air into

the product. This air is directed over the heating

element to create warm heated air out.

An over temperature switch (D) shuts the heater off

in the abnormal event a motor were to fail.

A tip over switch (E) shuts the heater off in the

event the product is tipped over.

Access to

Thermal

Limit Switch

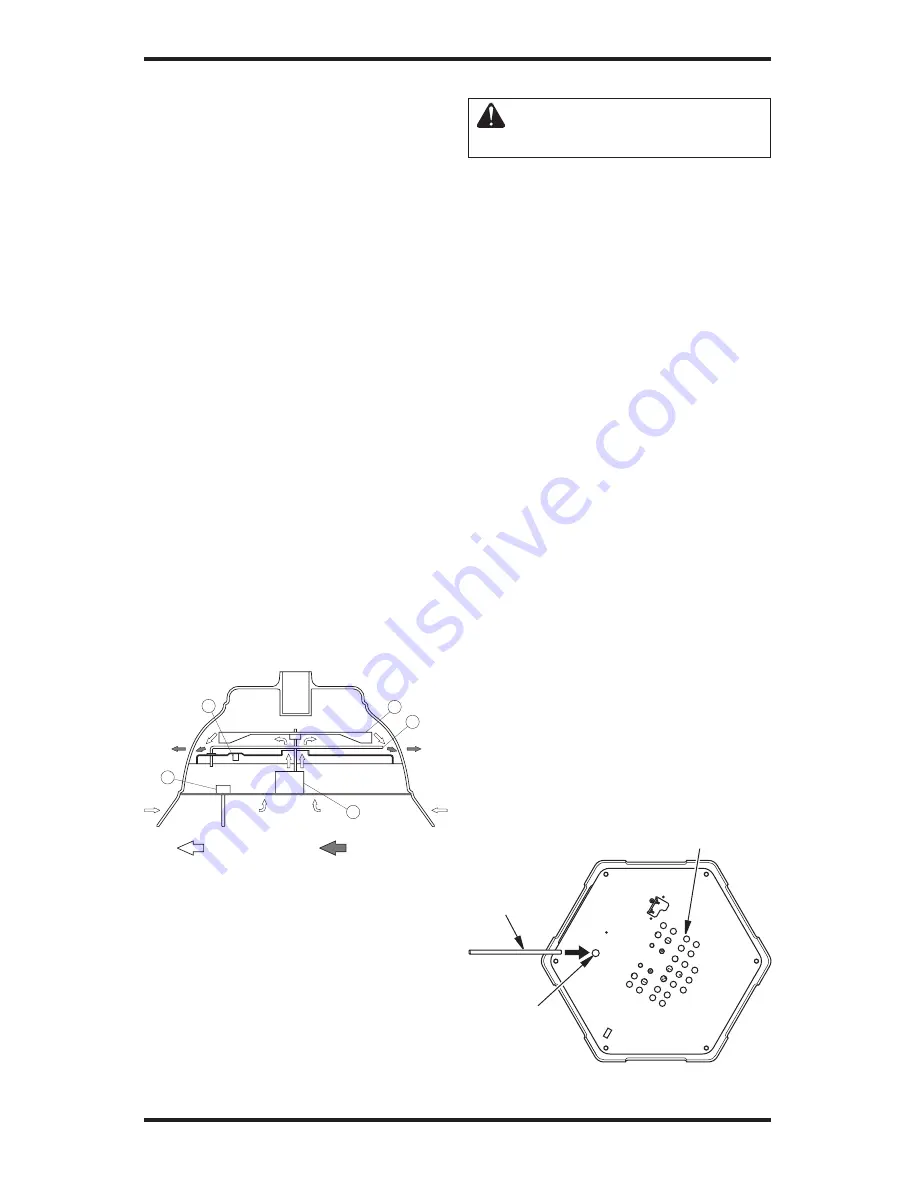

Figure 5 - Resetting Thermal Limit Switch

Push Rod

INSPECTION

Check for damage in the following ways:

1. Examine exterior of plastic shroud and inside

pole receiver for cracks. Replace shroud if

cracks are found.

2. Examine cover of on/off switch for cracks.

Replace switch if cracks are found.

A

C

Air To Be Heated

Heated Air

D

E

B

Figure 4 - System Operation

TROUBLESHOOTING

CAUTION: Risk of electric

shock.

If your product fails to operate:

1. Make sure the electrical outlet GFCI or circuit

breaker and extension cord is working.

2. Check for operation of tip switch. The ON/

OFF switch light can be on but the tip switch

OFF. Move product until a “click” is heard.

To prevent damage of tip switch post, do not

slide product.

3. Look for obstructions around fan. If you find

an obstruction, turn the product OFF and

UNPLUG THE PRODUCT. Have the product

serviced by a qualified individual.

4. Check for tripped thermal protector. Motor

and heating element do not operate. Wait 10

minutes for product to cool. Push reset button.

See

Thermal Limit Switch

below.

THERMAL LIMIT SWITCH

If product is used in temperatures below 75° F

(28.9° C), the limit switch should not require

resetting unless there is a malfunction. If a mal-

function does occur, have the product serviced by

an authorized service center.

Resetting Thermal Limit Switch

1. Unplug product.

2. Allow product to cool.

3. Turn product upside down.

4. Remove plug on bottom.

5. Insert provided plastic push rod through hole

and guide to small red button on thermal

limit switch (see Figure 5). A flashlight will

improve visibility.

6. Lightly push red button to reset switch.

Air Intake Openings