TB-3006

Page 2 of 4

Installation

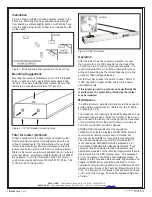

Figure 3 shows multiple mounting positions relative to the

bench top. Mounting may be accomplished by brackets

from shelving, vertical uprights, lights, or with chains hung

from the ceiling. Ensure that air flow is not impeded by the

method used.

Operation

After the ionizer has been securely mounted, connect

the power cord to the IEC connector on the back of the

unit and then to a convenient grounded receptacle. It is

recommended that the AC outlet be checked for proper

wiring and grounding, as the ionizer depends on a good

ground for offset voltage balancing.

Set the front panel rocker fan switch to either “HIGH” or

“LOW” speed fan. Higher air flow will result in a faster

neutralization rate.

If the ionizer is used in a manner not specified by the

manufacturer, the protection provided by the ionizer

may be impaired.

Maintenance

“As with all ionizers, periodic maintenance will be needed to

provide optimum performance.” (Reference: IEC 61340-5-

2:1paragraph 5.2.9).

The frequency of monitoring ionizers really depends on how

and where they are used. Since the majority of them use a

fan to transport the ions to the working area, the cleanliness

of the air directly affects their performance over time and

how often the emitters should be cleaned.

ANSI/ESD S20.20 specifies that the compliance

verification of ionizers be tested per ESD TR53. EIA-625

recommends checking ionizers every 6 months, but

this may not be suitable for many programs particularly

since an out-of-balance may exist for months before it

is checked again. ANSI/ESD S20.20 paragraph 6.1.3.1

Compliance Verification Plan Requirement states: “Test

equipment shall be selected to make measurements of

appropriate properties of the technical requirements that are

incorporated into the ESD program plan.” And paragraph

6.1.3.2. Compliance Verification Plan Guidance states: “In

addition to internal audits, external audits (Organization and

supplier of ESDS items) should be performed to ensure

compliance with planned requirements. Verifications should

include routine checks of the Technical Requirements in the

Plan. The frequency of verification checks should be based

on the control item usage, its durability and associated risk

of failure.”

Air filter

© 2013 DESCO INDUSTRIES INC.

Employee Owned

Figure 3. Mounting alternatives relative to the bench top

Mounting Suggestions

Mounting the ionizer is facilitated by five 1/4"-20 threaded

holes on each end and universal brackets supplied with

the unit. To avoid a potential shock hazard, be sure that

fasteners do not extend more than 1/2" into unit.

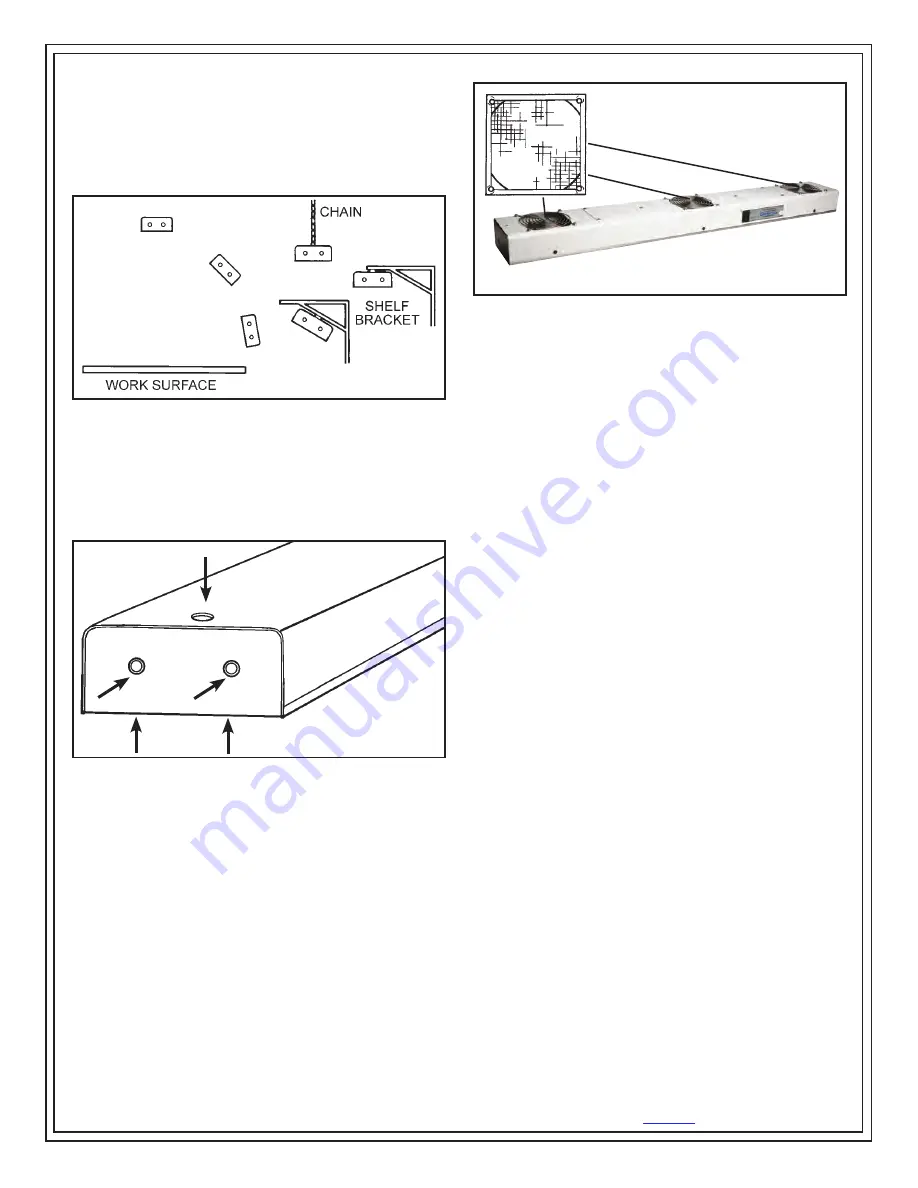

Figure 4. 1/4"-20 threaded mounting holes

Filter for Ionizer (Optional)

A filter is available for the High Output Overhead Ionizer.

Overhead ionizers operate more effectively when the air

is free of contaminants. The filter will allow the overhead

ionizer to operate longer between maintenance intervals.

Ensure that ionizer is turned off. Remove grills and install

filters on the ionizer using screws supplied (do not re-install

grills over filters). Replacement filters (Desco item #60455)

are available. For more information on the filter, call our

customer service department at 909-627-8178 (Chino, CA)

or 781-821-8370 (Canton, MA).

Figure 5. Filter for ionizer

DESCO WEST

- 3651 Walnut Avenue, Chino, CA 91710 • (909) 627-8178

DESCO EAST

- One Colgate Way, Canton, MA 02021-1407 • (781) 821-8370 • Website: