____________________________________________________________________________________

DESMI Pumping Technology A/S

21

Tagholm 1

9400 Nørresundby

–

Denmark

Tel: +45 96 32 81 11 Fax: +45 98 17 54 99

E-mail:

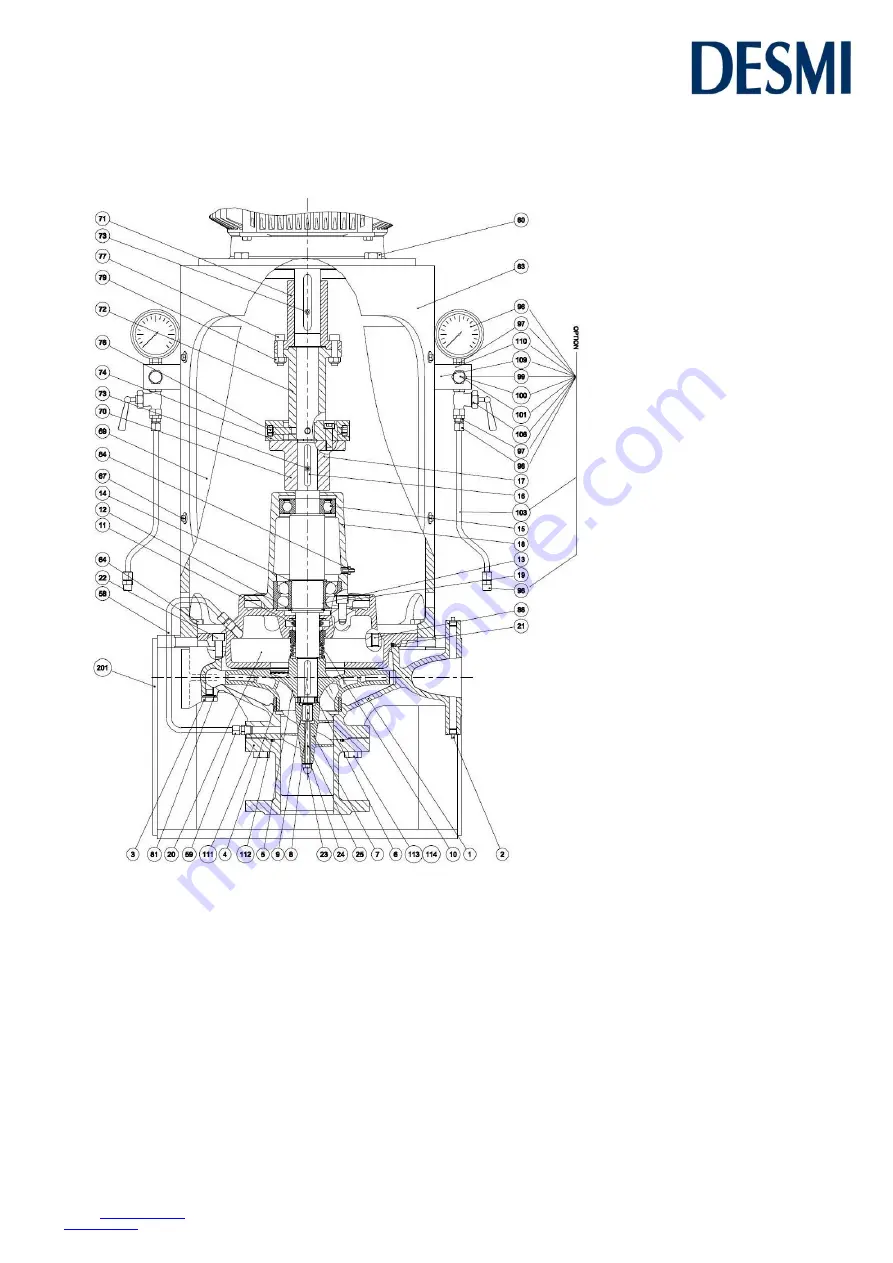

17. ASSEMBLY DRAWING AND SPARE PARTS LIST 65-265 WITH INDUCER

1 Pump casing

2 Pipe plug

3 Pige plug

4 Sealing ring

5 Impeller

6 Round nut

7 Inducer

8 Sunk key

9

Sunk key

10

Mech. shaft seal

11

Water deflector

12

Ring lock

13

Ball bearing

14

Support disc

15

Ball bearing

16

Sunk key

17

Shaft

18 Bearing housing

19

Allen screw

20

Shaft seal cover

21

O-ring

22

Allen screw

23 Domed cap nut

24 Spring washer

25 Stud

58

Copper pipe (For NSLV)

59 Hexagon nipple

60

Set screw

63

Bracket

64 Set screw

67

Set screw

69

Guard

70

Coupling part pump

71

Coupling part motor

72

Spacer

73

Pointed screw

74 Elastomer

76

Allen screw

77 Allen screw

79

Nut

81

Sealing washer

84

Lubricator nipple *

86

Point screw

96 Manometer

97

Reducing nipple

98 Hexagon nipple

99 T-piece

100 Bulkhead connection

101 Screw cap

103 Copper pipe

106 Manometer cock

107 Pipe plug

109 Set screw

110 Manometer fitting

111 Extend pipe

112 O-ring

113 Set screw

114 Nut

201 Base frame

*) 84 only combination 14