461933

Issue no : 08

Series : C

11/2016

17 / 64

The ‘M’ port is intended for the operation

of pilot valves. lt must not be used as a

source of air supply for other uses.

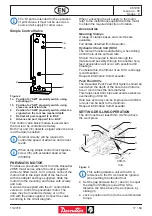

Simple Control Valve

1a

2

1b

3

4

Figure 4

1a Position for 'SW1' proximity switch, using

actuating pin

1b Position for 'SW1' proximity switch, using

sleeve on extension tube

2

Position for 'SW2' proximity switch, detects a

signal when the tool has reached depth

3

Retract Air port, tapped 1/8 in. BSP

4

Advance Air port, tapped 1/8 in. BSP

This control valve block module is used when

the tool is to be controlled remotely.

Both (1a) and (1b) detects a signal when the tool

is at the datum position.

External circuitry will be required to

control the speed of advance and retract

feeds.

When using simple control block replace

screw (35) with extended head screw

(383983).

PNEUMATIC MOTOR

Purchase a pneumatic motor from the Desoutter

2HM5 motor series when the unit is supplied

without a fitted motor. To fit a motor, connect the

motor shaft to the input shaft of the feed unit

with the adaptor and keys supplied. Slide the

motor into the mounting and fasten with screws

and nuts.

A valve kit is supplied with the A1 control block

version to control the pneumatic motor. The

valve may be mounted remotely, or on the

drill with the plate supplied. Connect the valve

according to the circuit diagram.

When connecting the air supply to the motor,

refer to the instructions supplied with the motor

to obtain the required direction of rotation.

Accessories

Mounting Clamps

A range of clamps bases and columns are

available.

Full details obtained from Desoutter.

Hydraulic Check Unit (HCU)

The tool will function satisfactorily, when drilling

a blind hole at the set feed rate.

Should it be required to break through the

material and possibly through into another hole,

feed acceleration will occur with possible drill

breakage.

To obviate this, the fitment of an HCU is strongly

recommended.

Request information from Desoutter.

Peck Feed Drills

The Desoutter Peck Feed Drill System should be

used when the depth of the hole to be drilled is

five or more times the hole diameter.

This helps clear drill chips and avoids excessive

overheating of drill bit.

Hole size accuracy can be improved and drill bit

run-out can be kept to the minimum.

Request information from Desoutter.

SETTING DRILLING OPERATION

The drill must be at least 6mm (0.25in) above

the work piece.

7

6

4

9

2

3

1

8

1

HCU

20mm

min.

Figure 5

This setting details a unit with a HCU,

reference to the HCU should be ignored

when setting the standard tool.

●

Set the gap between the (1) and (2) to equal

the depth of drilling required PLUS the

distance the bit is above the work piece, by

sliding (3).

●

Lock in position with (4) to the recommended

torque.