10/2010

12 / 80

6159948450

Issue no: 06

Series: C

Original instructions.

© COPYRIGHT 2010, DESOUTTER HP2

7BW UK

All rights reserved. Any unauthorized use

or copying of the contents or part thereof

is prohibited. This applies in particular to

trademarks, model denominations, part numbers

and drawings. Use only authorized parts. Any

damage or malfunction caused by the use of

unauthorised parts is not covered by Warranty or

Product Liability.

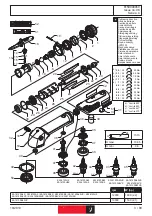

INSTRUCTIONS

This product is designed for removing

material using abrasives. No other

use permitted. For professional use

only. Before servicing the power tool,

the supply of compressed air must be

disconnected or shut off.

If a grinding wheel is broken, a careful

investigation shall be made by the

user to determine the correct cause.

If the failure occurs while the tool is in

operation, the wheel manufacturer and

the tool manufacturer should be notified

promptly.

The rotor blades in this tool have a

PTFE content. The normal health and

safety recommendations concerning

PTFE must be observed when handling

these rotor blades.

1. Do not smoke.

2. Motor components must be washed

with cleaning fluid and not blown

clear with an air line.

3. The silencer must be replaced when

dirty, do not clean and re-use.

4. Wash hands before commencing any

other activity.

Risk of icing.

Ice can cause continued running after

the start lever has been released.

Always use a dry air supply to avoid the

risk of icing.

When disposing of components,

lubricants, etc … ensure that the

relevant safety procedures are carried

out.

The tool is designed for a working

pressure of 6.3 bar (90 psig). The

compressed air must be clean. The

installation of a filter is recommended.

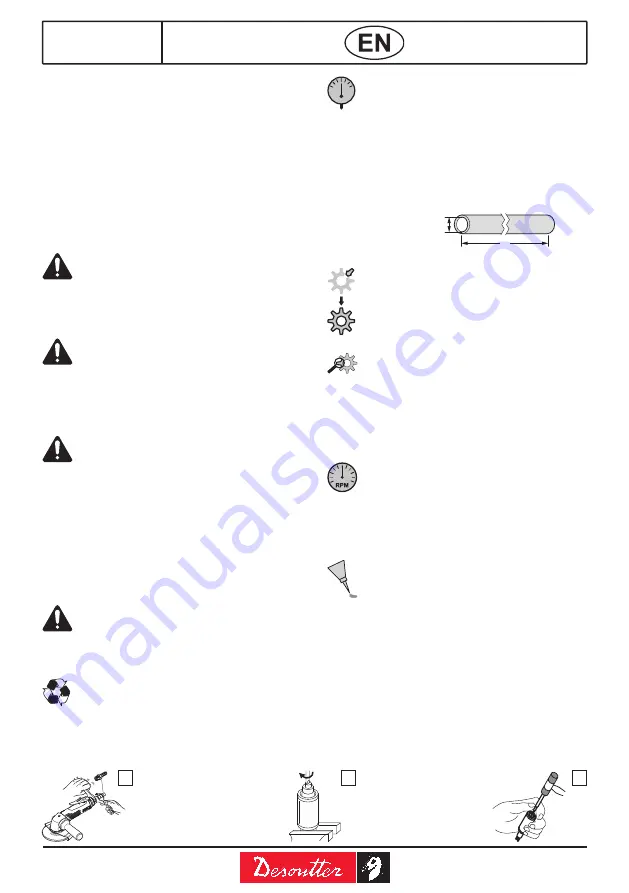

For maximum efficiency and

performance, comply with the

specification of the air hose (antistatic

hose). (Refer to figure no.1 for

compressed air connection).

A: Ømini = 13mm (1/2")

B: 7 m max.

A

B

The use of spare parts other than those

originally supplied by the manufacturer

may result in a drop in performance or

in increased maintenance and level of

vibration and in the full cancellation of

the manufacturer’s liability.

To obtain maximum efficiency from the

pneumatic tool, preserve its features

and avoid repeated repairs, a routine

inspection and repair programme

are recommended at least every 500

hours, the intervals between the various

inspections depending on the amount of

exertion on the power tool.

Check the free speed of the tool

at regular intervals and after each

operation or maintenance task. Remove

the abrasive to check the speed. The

maximum allowed speed shown on

the tool must not be exceeded and the

vibration level must not be excessive.

This tool is fitted with blades which can

operate without lubricated air. However,

a small amount of oil allows the tool to

provide full power and lengthens its life.

The use of dry air with no trace of oil

may reduce the life of blades.

1

2

3