English

3 / 8

TECHNICAL MANUAL

www.desouttertools.com

1/2"

Ø3 4H11

8

113

15.5

50

10

6

Ø28

Ø12 m6

8

Ø51

Ø43

366

45

35

53

R9

±0,15

35

20°

±0,15

35

M8 6H

M8 6H

Ø49

+0

- 0,10

±0,15

Disassembly

1- disconnect the cables from the tool

2- disassembling the output shaft

• lay the machine horizontally on a table

• remove the retainer pin from the output shaft

• be careful of the spring reaction

3- disassembling the motor

• place a special wrench of 48mm across flats in a vice

• the machine should

imperatively

be placed in the special

wrench on the flats which are closest to the motor

• untighten the motor with a special 40mm wrench - left-hand

thread

• heat the casing with a torch if necessary

• remove the coupling sleeve and the drive pinion

4- disassembling the reduction gear stages

• place a special wrench of 48mm across flats in a vice

• the machine should imperatively be placed on the flats of the

gear ring of the first 2 stages

• using a torch, heat the connecting casing of the motor

• using a special wrench of 40mm across flats, untighten the

motor - left-hand thread - and its connecting casing

• place the special wrench of 40mm across flats in the vice

• using the special wrench of 48mm across flats, untighten the

connecting casing of the motor after heating it with a torch

• remove washers

• extract the planet cages of the 1st and 2nd stages

• the machine should imperatively be placed on the flats of the

strain gauge

• using a 48mm wrench, untighten the gear ring of the first

2stages

• extract the 3rd stage planet cage

• using a 48mm wrench, untighten the 3rd stage gear ring

• extract pins, planet wheels and needle bearings from the

planet cages

5- disassembling the cap from the flange

• remove the circlip from the flange

• press the cap out of the flange

• remove the circlip from the cap bearing

• remove the cap bearing

• to remove the spring guide, extract the cap circlip

Tools required for complete disassembly / Reassembly

Special wrench

Item

Part number

Special wrench of 40

6159606900

Special wrench of 48

6159605380

Pin wrench

6158020110

The other tools are standard tools used in mechanical workshops

Complete reassembly

Reassembly does not pose any problem in particular.

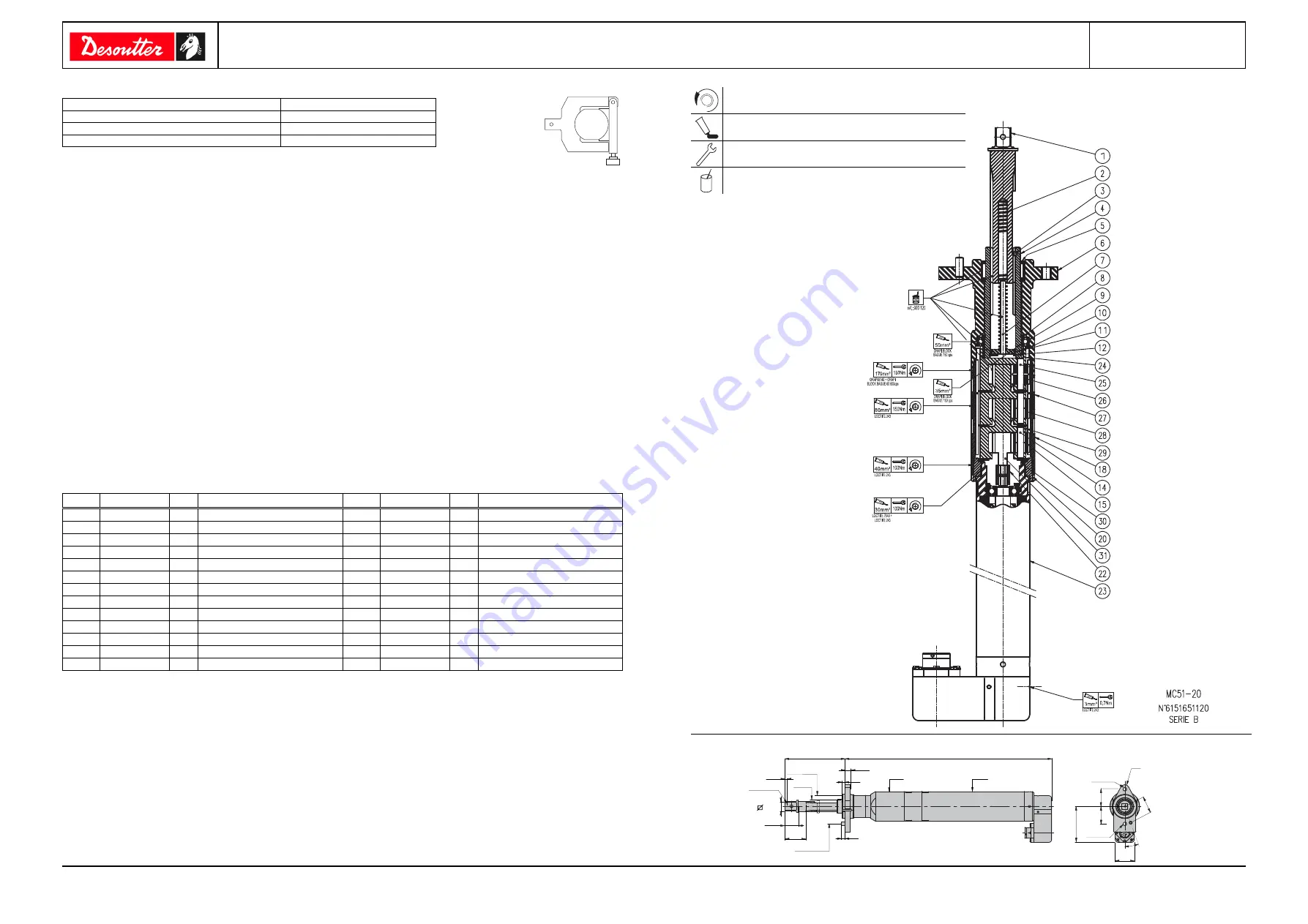

It is important to follow all the indications which are provided, in the form of pictograms, on the drawing opposite.

Part list:

Item

PT N°

Qty

Description

Item

PT N°

Qty

Description

1

6155210720

1

Output shaft 1/2''

2

6156811000

1

Spindle spring

3

6157901390

1

Pin

4

6152250490

1

Bit holding cap

5

6157850670

1

Needle socket

6

6155704360

1

Flange

7

6155952330

1

Spring guide

8

6156890350

1

Circlip

9

6157580570

1

Bearing

10

687.52

1

Circlip

11

6156581630

1

O-ring

12

6156870350

1

Circlip

14

6157900520

6

Pin

15

6157880160

12

Needle bearing

18

6154760620

1

Gear ring

20

6155664830

1

Connecting casing

22

6155751020

1

Coupling sleeve

23

6153941640

1

Motor

24

6154751360

1

Planet cage

25

6157901200

3

Pin

26

6154701010

3

Planet wheel

27

6154760640

1

Gear ring

28

6154700940

6

Planet wheel

29

6154751140

2

Planet cage

30

6156420650

3

Washer

31

6155800920

1

Drive pinion

Meaning of the pictograms

Left-hand thread

When reassembling, apply the recommended glue

When reassembling, tighten to the required torque

When reassembling, lubricate with the required grease