WIRING PROCEDURE

For systems using conduit, modules must be wired

using a short piece of suitable flexible conduit to allow

optical alignment of the modules. Ensure that all cables

are terminated properly. Open Path Eclipse screw

terminal torque range is 3.5–4.4 lb.-in. (0.4–0.5 N·m).

Cable shield, if used, should be properly terminated. If

not terminated, clip the shield wire off short and insulate

it within the detector housing to prevent the shield wire

from accidentally contacting the detector housing or

any other wire.

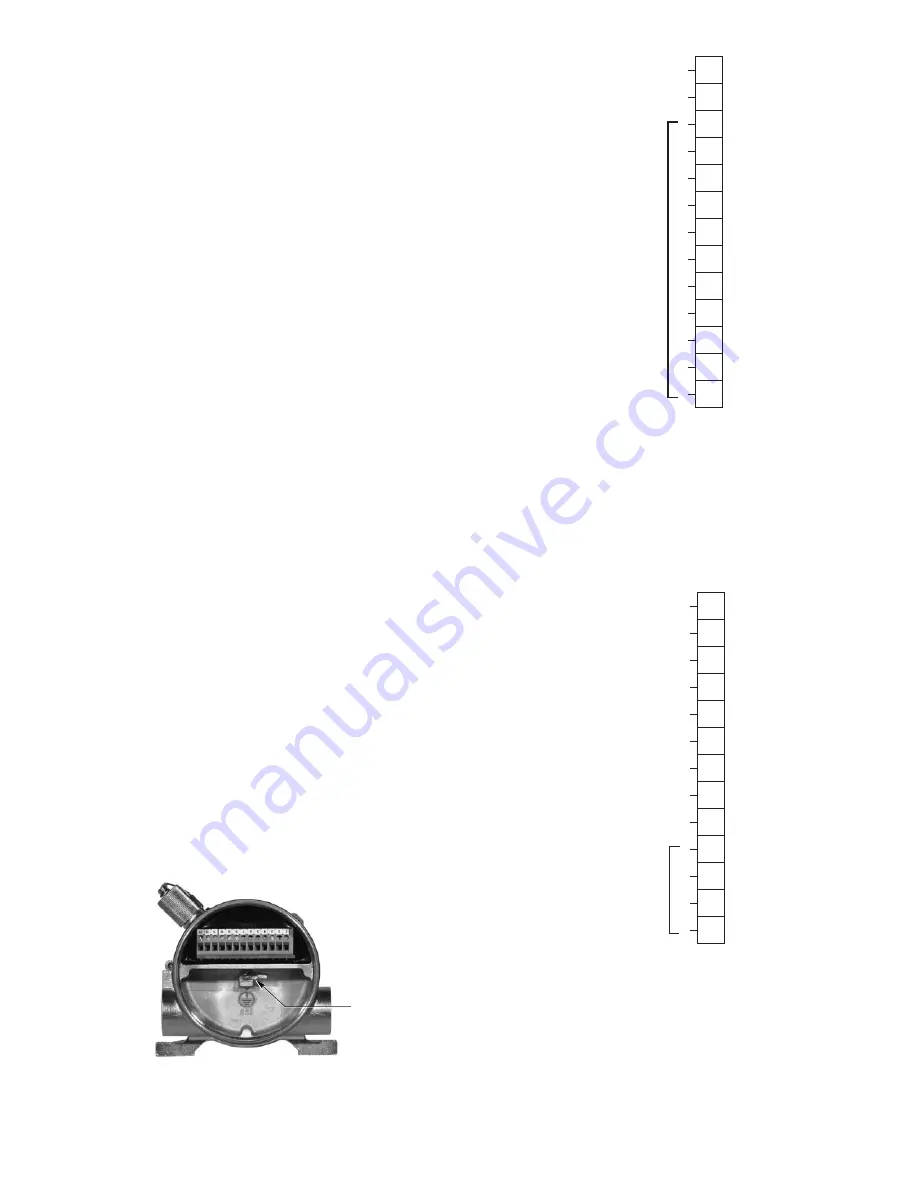

Figure 7 shows the wiring terminal strip located inside

the detector’s integral junction box.

Figure 8 shows the wiring terminal configuration for the

OPECL transmitter. (The transmitter requires only

operating power.)

Figure 9 shows the wiring terminal configuration for the

OPECL receiver without relays.

Figure 10 shows the wiring terminal configuration for the

OPECL receiver with relays.

Figures 11 through 14 show the 4 to 20 mA output of the

OPECL receiver in various wiring schemes.

Figure 15 shows the OPECL wired to a Model R8471J

Controller.

NOTE

The OPECL housing must be electrically

connected to earth ground. A dedicated earth

ground lug is provided for this purpose.

NOTE

For proper HART communication, it is required

that an analog signal loop resistance of 250 to 500

ohms be present at the receiver analog output

terminals. See Figure 16 for benchtop test wiring.

For OPECL systems using HART communication,

the maximum wiring distance is 2,000 feet.

13

95-8556

2.1

EARTH GND LUG

A2084

Figure 7—Terminal Strip Located Inside Wiring Compartment

–24 VDC

–24 VDC

+24 VDC

+24 VDC

CALIBRATE

+ 4-20 MA

– 4-20 MA

RS-485 A

RS-485 B

NO USER CONNECTION

1

2

3

4

5

6

7

8

9

10

11

12

13

A2196

Figure 9—Wiring Terminal Identification for OPECL Receiver

without Relays

–24 VDC

+24 VDC

NO USER CONNECTION

1

2

3

4

5

6

7

8

9

10

11

12

13

A2197

Figure 8—Transmitter Wiring Terminal Identification