The shorting plug, which attaches to the connector

board, must be in place at all times that the sensor is

operating.

The calibration cup can remain on the sensor after

calibration without interfering with normal operation.

By connecting a length of tubing from the calibration

cup back to the transmitter location, the operator can

make calibration adjustments and also control the

flow of calibration gas from the same location.

IMPORTANT

The operator must frequently inspect the filter on

the calibration cup. This filter must be kept

clean. If the filter should become clogged by

environmental contaminants such as dirt, oil,

paint, etc., the flow of gas to the sensing element

will be restricted. This can significantly reduce

the sensitivity and response time of the sensor,

thereby impairing the ability of the system to

respond to a hazardous condition. Problems of

this nature will not be detected by the system’s

diagnostic circuitry or during routine calibration.

If the filter becomes dirty and cannot be properly

cleaned, the calibration cup must be replaced.

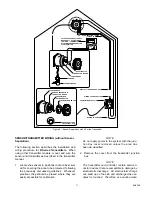

Sensor Installation

For proper operation, the sensor must be oriented

with the filter pointing down. Install the sensor in the

lower 3/4 inch NPT opening on the junction box.

Connect the conduit to the upper opening.

The sensor junction box can be mounted to a wall or

post, or it can be suspended by the conduit. The

junction boxes should be electrically connected to

earth ground.

Wiring Requirements

Three wire cable is used for connecting the sensor to

the transmitter and also for connecting the transmitter

to the controller. The use of shielded cable is

required for connecting the sensor and transmitter,

and is highly recommended for connecting the trans-

mitter and controller.

Three conductor cable with a

foil shield is recommended. The shield of the cable

connecting the sensor and transmitter should be

open at the sensor junction box and connected to

earth ground at the transmitter junction box. The

shield of the cable connecting the transmitter and

controller should be open at the transmitter junction

box and connected to earth ground at the controller.

The maximum distance between the sensor and

transmitter is limited by the resistance of the connect-

ing wiring, which is a function of the gauge of the wire

being used. Note that maximum wiring distances

also vary with the specific transmitter model being

used. Table 4 shows the maximum separation dis-

tance allowed for a given wire size when using K

Series Transmitters. For other transmitter models,

refer to the transmitter manual for specific instruc-

tions.

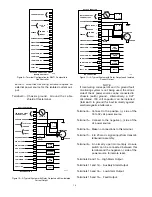

Sensor Voltage Adjustment (K Series Transmitters

only)

When using a sensor separation kit with a K Series

Transmitter, an adjustment to the sensor voltage is

required to assure proper operation. This adjustment

should be performed at the time of system startup,

before calibration is performed.

The combustible gas sensor is designed to operate at

3.3 volts dc. Greater voltages will shorten sensor life

and lower voltages will reduce sensitivity to certain

gases. The sensor supply voltage is factory adjusted.

However, re-adjustment is necessary if the sensor

and transmitter are separated.

CAUTION

Sensor voltage adjustment requires the removal

of the junction box cover at both the sensor and

transmitter locations. The area must be de-clas-

sified when removing the junction box cover with

power applied to the system.

To adjust sensor voltage, connect a digital voltmeter

WHT and –BLK on the connector board

inside the

sensor junction box

(see Figure 5). Install

the transmitter extender plug between the transmitter

module and the connector board in the

transmitter

junction box

to allow access to potentiometer R18 on

the transmitter module. Adjust R18 to obtain a read-

ing of 3.3 volts on the voltmeter.

10

Table 4—Maximum Separation Distances – Sensor to K Series

Transmitter

Shielded

Recommended Maximum

Wire Size

Transmitter to

(AWG)

Sensor Distance*

Feet

Meters

18

50

15

16

75

23

14

125

38

*Sensor voltage adjustment is required.