SERIES 60 ENGINE OPERATOR'S GUIDE

OAT — Organic Acid Technology.

An inhibitor system based on

organic acid inhibitors, instead of

traditional North American inhibitor

formulations.

SCA — Supplemental Coolant

Additive. SCAs are used in a

preventive maintenance program to

prevent corrosion, cavitation, and the

formation of deposits.

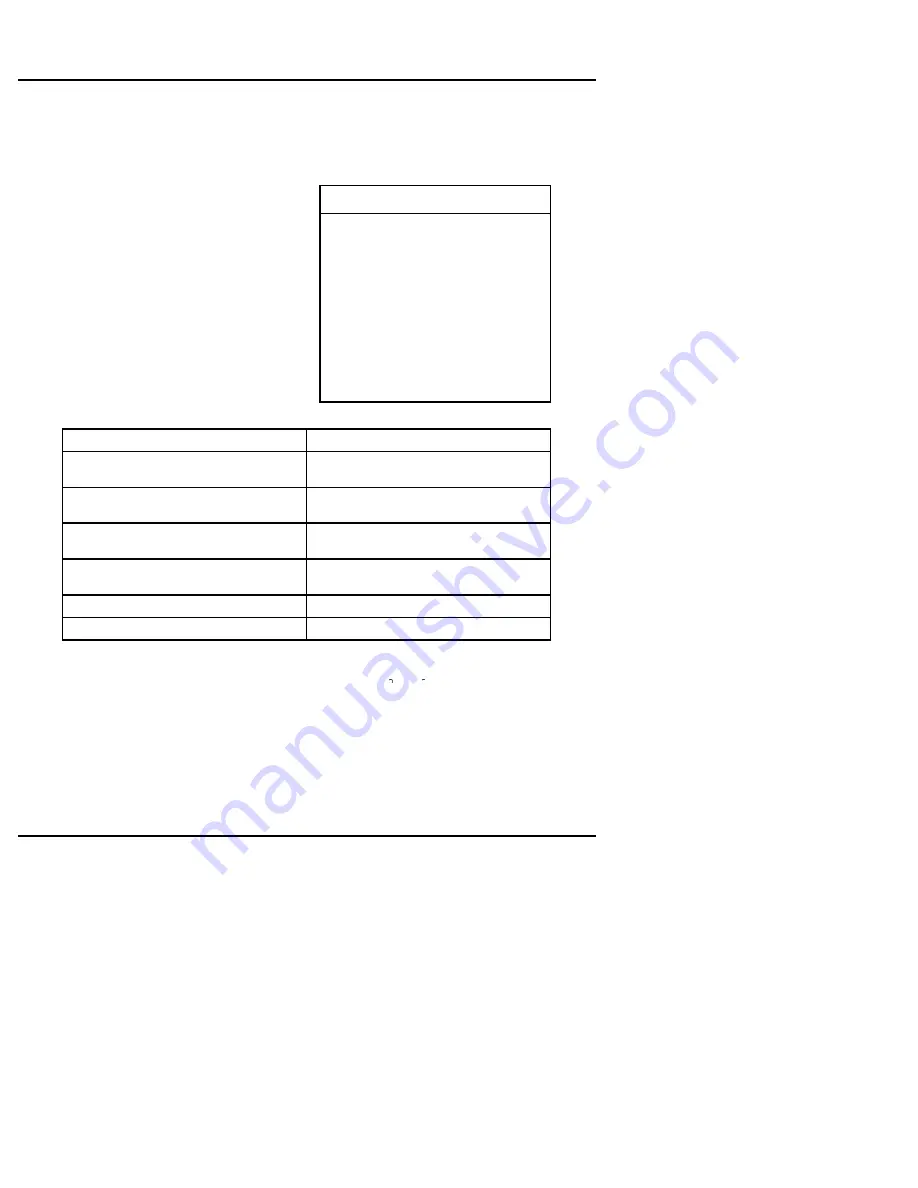

Approved Coolants

The approved and preferred

coolants for Series 60 engines

are listed in Table 21. Once installed,

these coolants should be maintained

according to the procedures discussed

under Maintenance in this section.

NOTICE:

Required specifications for water,

ethylene glycol, propylene glycol,

inhibitor packages and inhibitor

concentration are included in

this section. To avoid possible

engine damage from inadequate

or overconcentrated coolant,

this information should be read

thoroughly before the coolant is

replaced.

Coolant Fill Option

Product

Ethylene Glycol & Water + Corrosion

Inhibitors

1

DDC Power Cool

Commercial Equivalent of DDC Power

Cool

Fully Formulated TMC RP-329 Type A

Antifreeze & Water

Propylene Glycol & Water + Corrosion

Inhibitors

1

DDC Power Cool Plus

Ethylene Glycol & Water + OAT

Inhibitors

DDC Power Cool Plus

Water Only + Corrosion Inhibitors

2

Water + DDC Power Cool 3000

Water Only + OAT Inhibitors

2

Water + DDC Power Cool Plus 6000

1

Preferred Coolant

2

Water-only coolant systems offer no freeze protection and should not

be used where ambient temperatures can fall to 32 F (0 C).

Table 21

Initial Fill Coolant Options

All information subject to change without notice. (Rev. 01/04)

95

6SE484

0401

Copyright © 2004 DETROIT DIESEL CORPORATION