55

G. How to Select Coolant

Antifreeze

Use genuine Detroit Diesel Power

Cool

or an equivalent fully formulated,

inhibited ethylene glycol (IEG)-base

coolant (low silicate formulation) that

meets or exceeds the standard of

either the GM 6038-M formulation (GM

1899-M performance), or ASTM D

4985 requirements.

A 50%

Power Cool

antifreeze/water

solution is normally used as a factory

fill. Concentrations over 67% are not

recommended because of poor heat

transfer capability, adverse freeze pro-

tection and possible silicate dropout.

Concentrations below 33% offer little

freeze, boilover or corrosion protection.

If Detroit Diesel Power Cool or

equivalent precharged inhibited ethy-

lene glycol (IEG) is not used, Detroit

Diesel Maintenance Product supple-

mental inhibitors must be added to

the coolant at initial fill. Inhibitor lev-

els in all coolants used must be

maintained at proper concentration

thereafter. Refer to “Proper SCA

Dosage for Initial Fill and Main-

tenance Requirements” chart in this

section. Refer to “Inhibitor Test

Procedures” (page 58) for required

inhibitor levels.

Antifreeze solution should be used

year-round to provide freeze and boil-

over protection as well as a stable envi-

ronment for seals and hoses.

In extremely hot environments, clean,

soft, properly inhibited water may be

used if Detroit Diesel Maintenance

Product supplemental corrosion

inhibitors are also added in the right con-

centration. If water is used, supplemen-

tal coolant additive levels should be

increased from 3% to 6% by volume

(refer to

Specifications

, pages 73-74).

Only non-chromate inhibitors

should be used with coolant solutions.

Coolant must be tested for required

inhibitor levels at the intervals shown

under “Coolant Test Intervals” in this

section. Adjust the concentration if not at

the proper protection level.

Mix coolant/water solution at the proper

concentration before adding to the cool-

ing system. This should prevent over- or

under-coolant concentration problems.

Methyl alcohol-based antifreeze is

not recommended for use in Detroit

Diesel engines because of its effect

on the non-metallic components of

the cooling system and its low boil-

ing point.

Methoxy propanol-based anti-

freeze is also not recommended

because it is not compatible with

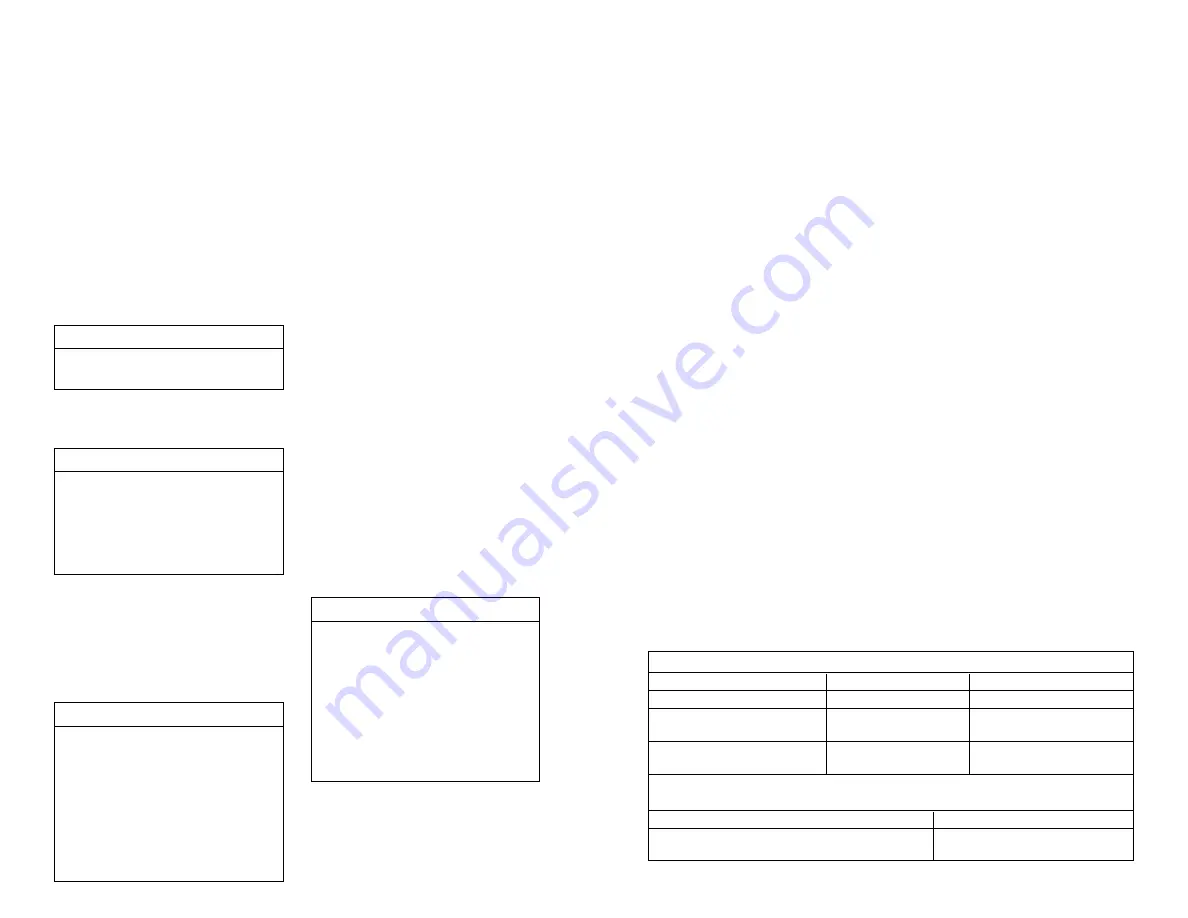

Initial Fill SCA Dosage

Coolant

Coolant Element

Liquid

Precharged IEG* & Water

NONE

NONE

IEG & Water

Select Element from

3% by Volume or 1 Pint

Specifications Page

per 4 Gallons

Water only

Select Element from

6% by Volume or 1 Quart

Specifications Page

per 4 Gallons

*Such as Detroit Diesel Power Cool

®

antifreeze, or equivalent.

Maintenance SCA Dosage

Coolant Element

Liquid

Select Element from

Specifications

Page

0.6% by Volume or 1 Pint

per 20 Gallons

Proper SCA Dosage for Initial Fill and Maintenance Requirements

state and/or federal (EPA) recom-

mendations.

2. Fill a new replacement cartridge

about two-thirds full with clean

fuel oil. Coat the seal gasket light-

ly with clean fuel oil.

3. Install the new cartridge and tighten

by hand until the gasket touches

the mounting adaptor head.

Tighten an additional one-half turn.

4. Start the engine and check for

leaks.

If the engine fails to start after re-

placement of the fuel strainer and/or

filter elements, the fuel system will

require priming with tool J 5956 (or

equivalent). Authorized Detroit Diesel

service outlets are properly equipped

to perform this service.

54

NOTICE:

Overtightening may distort or crack

the filter adaptor.

NOTICE:

To improve engine starting, have

replacement elements filled with

fuel and ready to install immediate-

ly after used elements are re-

moved. This will prevent possible

siphoning and fuel system aeration.

NOTICE:

Under no circumstances should the

starting motor and fuel pump be

used to prime the fuel filter and

strainer. Prolonged use of the start-

ing motor and fuel pump to prime

the fuel system can result in damage

to the starter, fuel pump, and injec-

tors and cause erratic running of the

engine due to the amount of air in

the lines and filters.

F. Engine Out of Fuel—

How to Restart

When an engine has run out of fuel,

there is a definite procedure to follow

when restarting it.

1. Fill the fuel tank with the recom-

mended grade of fuel. If only par-

tial filling is possible, add a

minimum of 10 gallons (38 liters)

of fuel to the tank.

2. Remove the fuel strainer/water

separator from its cover, fill it with

fuel, and reinstall it.

3. Remove the fuel filter from its

cover, fill it with fuel, and reinstall

it.

4. Start the engine, and check fuel fil-

ter and strainer for leaks.

If the engine fails to start after re-

placement of the fuel strainer and/or

filter, the fuel system will require

priming with tool J 5956 (or equiva-

lent). Authorized Detroit Diesel ser-

vice outlets are properly equipped to

perform this service.

NOTICE:

Under no circumstances should the

starting motor and fuel pump be

used to prime the fuel filter and

strainer. Prolonged use of the start-

ing motor and fuel pump to prime

the fuel system can result in dam-

age to the starter, fuel pump, and

injectors and cause erratic running

of the engine due to the amount of

air in the lines and filters.

Summary of Contents for 92 Series

Page 41: ...NOTES 77 NOTES 76 ...

Page 42: ...NOTES 78 ...