SECTION 4

DDFP

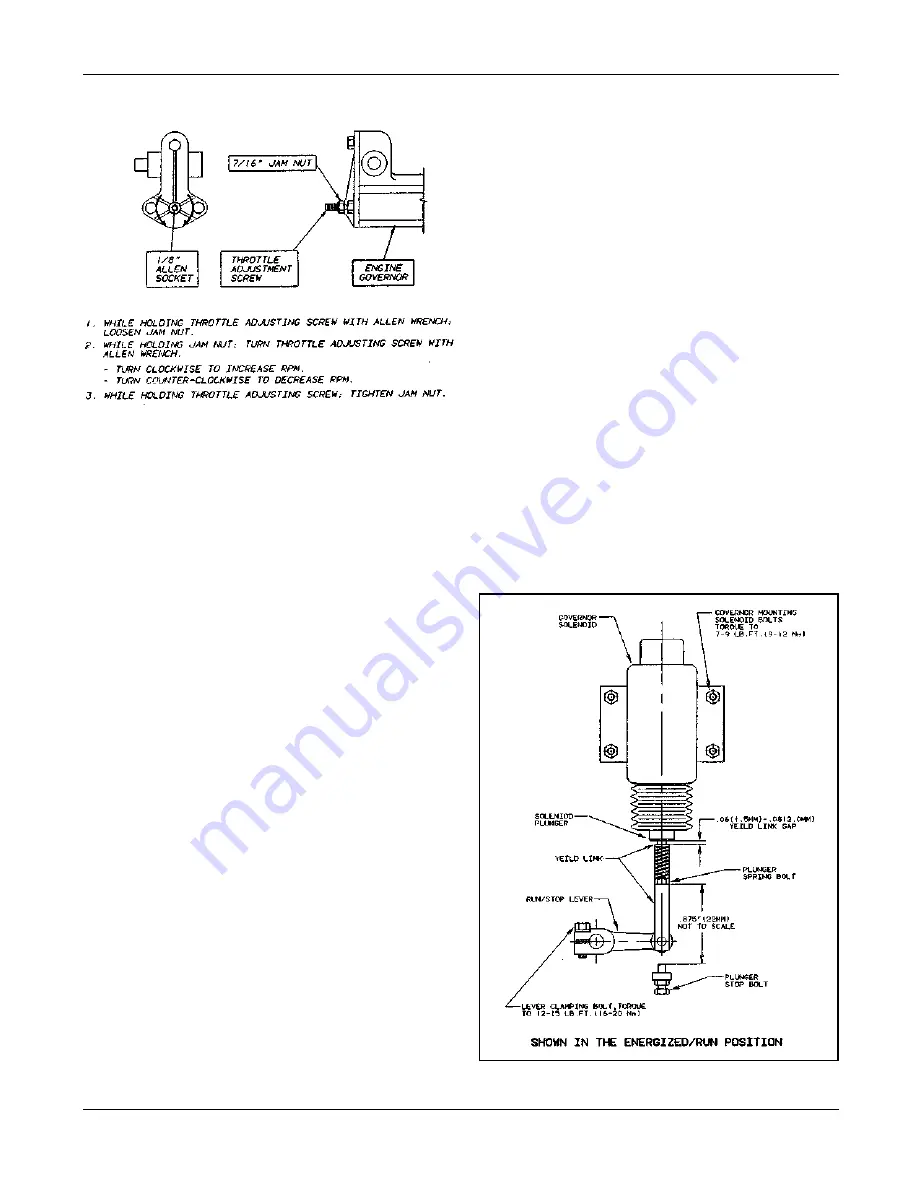

GOVERNOR SOLENOID-ADJUSTMENT

The mechanical governor is controlled by a DC solenoid. A

spring loaded yield link is included as part of the e xternal

linkage from the run/stop lever to governor solenoid.

IMPORTANT:

To insure the engine will produce rated

nameplate horsepo wer, the g ap be-

tween the yield link and the solenoid

plunger must be properly adjusted.

(Refer to Figure 3.)

YIELD LINK GAP CHECK

Position the mode selector switch on the instrument panel

(Fig. 3, Page 32), to the MANUAL position. Manually push

the solenoid plunger into the solenoid. When the plunger is

at full tra vel, the hold coil magnetic f ield will hold the

plunger, linkage and the run/stop le ver in the run position.

Push on the plunger spring bolt, not the linkage or the lever.

Check the gap at the narrowest point and adjust if necessary,

(Refer to Fig. 3). After the check is completed return the

mode selector switch to the AUTOMATIC position.

WARNING:

DO NOT lea ve the MODE SELECT OR

switch in the MANU AL R UN position

during AUTOMATIC operation. (The

controller will be una ble to stop the

engine and O VERHEAT D AMAGE

WILL RESULT)

Page 46-A

53 SERIES ENGINES

Adjust the Gap by loosening the Lever Clamping Bolt (Fig.

3), and rotating the Run/Stop Lever on the governor shaft to

the desired position and re-torque the clamping bolt. Re-

check the gap and repeat adjustments if necessary. After the

check is completed return the mode selector switch to the

AUTOMATIC position.

After the gap has been properly adjusted, and with the gov-

ernor solenoid de-ener gized, in the ST OP position, adjust

the Plunger Stop Bolt. Set at zero clearance with the Plunger

Spring Bolt, then turn one full turn clockwise and lock with

the Jam Nut.

WARNING:

DO NOT lea ve the MODE SELECT OR

switch in the MANU AL R UN position

during AUTOMATIC operation. (The

controller will be unable to stop the

engine and O VERHEAT D AMAGE

WILL RESULT)

When the adjustments have been completed, start the engine

from the ENGINE CONTROLLER (AEC), using the MAN-

UAL mode. Verify the Gap Dimension again, then stop the

engine. Return all controls to the AUTOMATIC mode.

Figure 3 - Shown in the Energized/Run Position

Figure 2 - Speed Adjustment 71 & 92 Series