For best overall performance, a coolant consisting of 50% concentration of antifreeze (50% antifreeze, 50% water) is

recommended. An antifreeze concentration of over 60% (60% antifreeze, 40% water) is

not recommended

due to poor heat

transfer, reduced freeze protection, and possible silicate dropout. An antifreeze concentration below 40% (40% antifreeze,

60% water) offers too little freeze and/or corrosion protection and is

not recommended

.

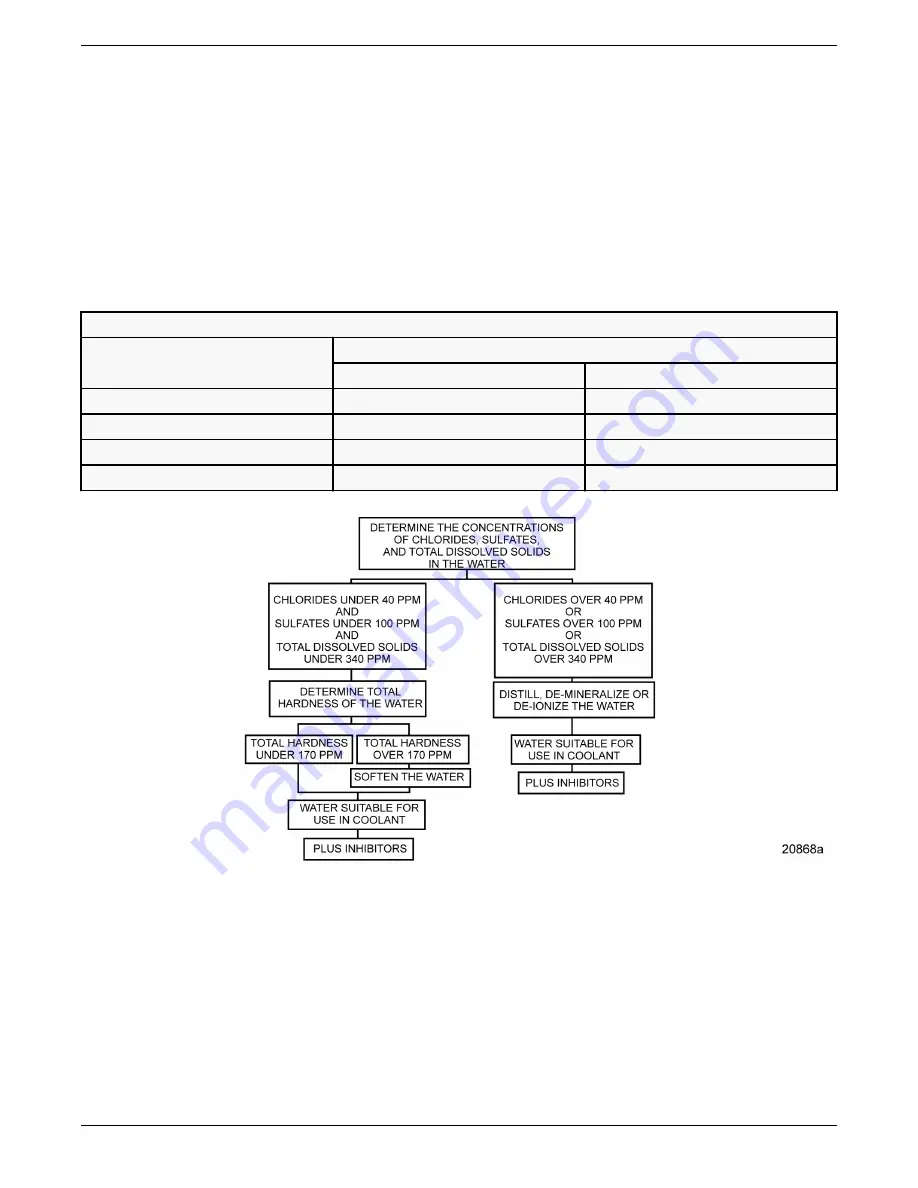

WATER REQUIREMENTS

Distilled or de-ionized water, which eliminates the adverse effects of minerals in tap water, is preferred. High levels of

dissolved chlorides, sulfates, magnesium, and calcium in some tap water causes scale deposits, sludge deposits and/or

corrosion. These deposits have been shown to result in water pump failures and poor heat transfer, resulting in overheating. If

tap water is used, the mineral content in the water must be below the maximum concentration listed in the table below.

Table 17.

Maximum Mineral Concentration in Water

Minerals

Maximum Concentration

Parts per Million

Grains per Gallon

Chlorides

40

2.5

Sulfates

100

5.8

Total Dissolved Solids

340

20

Mag Calcium Content

170

10

Figure 16. Procedure To Evaluate The Quality Of Water

Recycled Antifreeze

Antifreeze coolant made with ethylene or propylene glycol recycled by reverse osmosis, distillation, and ion exchange and

properly re-inhibited to meet ASTM D6471 or D6472 requirements has been demonstrated to provide service equivalent to

virgin antifreeze. Recycled antifreeze coolants of these types are preferred. However, suppliers of these recycled glycols must

provide evidence the product is free of contaminates listed below:

• Acetates

• Acetone

• Ammonia

• Boron

15 How to Procedures

58

All information subject to change without notice.

Copyright © 2019 DETROIT DIESEL CORPORATION

DDC-SVC-MAN-0207