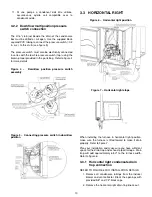

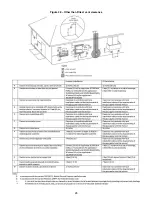

Figure 14 – Two stage gas valve

Figure 15 – Adjustment screw

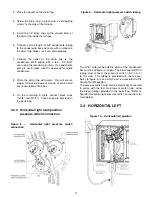

Table 4 – Inlet gas pressure

Gas Pressure in w.c. (psig)

Natural gas

Propane

Maximum

10.5 (0.38)

13.0 (0.47)

Minimum

4.5 (0.16)

11.0 (0.40)

Table 5 – Outlet gas pressure

Gas Pressure in w.c.

Natural Gas

Propane

High fire (100%)

3.0

8.6

Low fire (70%)

1.55

5.0

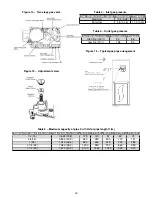

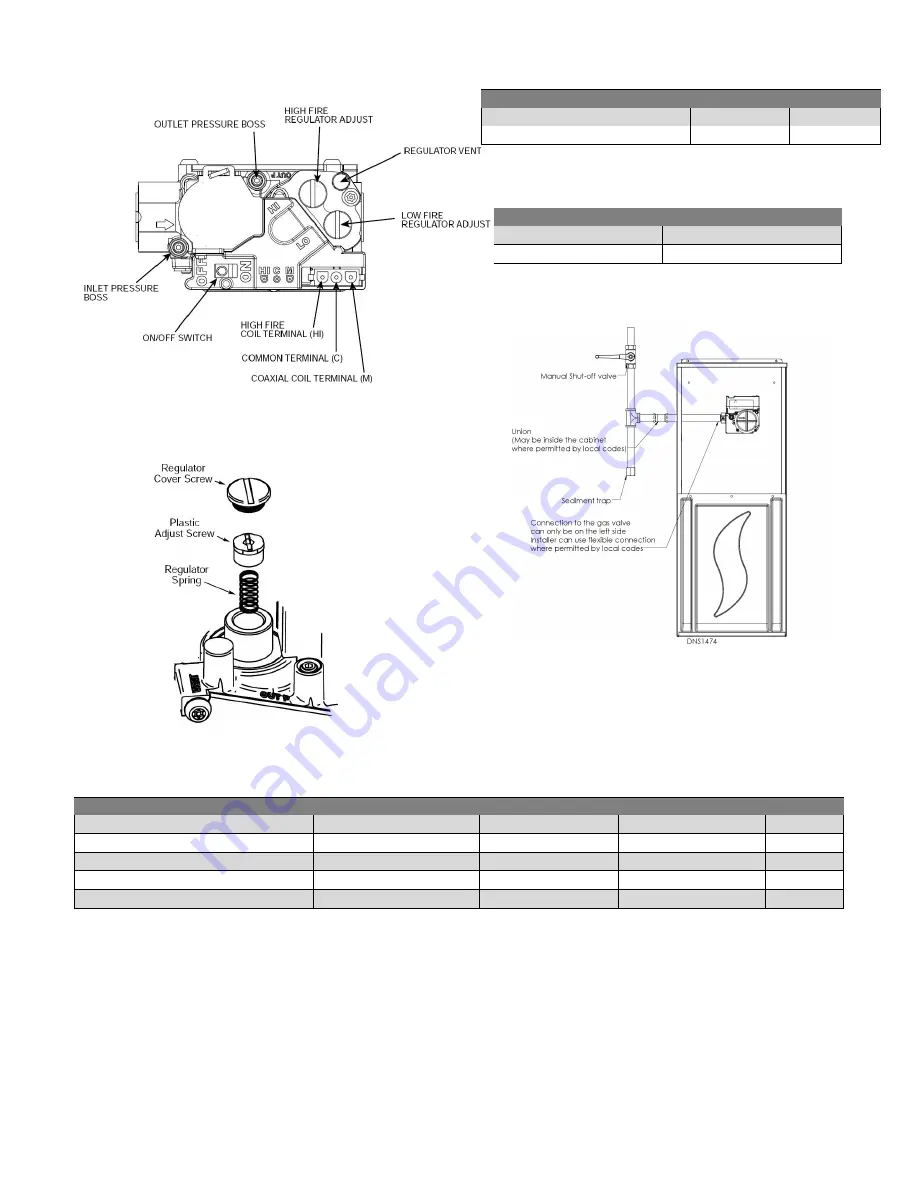

Figure 16 – Typical gas pipe arrangement

Table 6 – Maximum capacity of pipe Cu.ft./Hr for pipe length ft (m)

Nominal Iron pipe size in. (mm)

Internal dia. in. (mm)

10 (3.0)

20 (6.0)

30 (9.1)

40 (12.1)

50 (15.2)

1/2 (13)

0.622 (158)

175

120

97

82

73

3/4(19)

0.824 (20.9)

360

250

200

170

151

1 (25)

1.049 (26.6)

680

465

375

320

285

1-1/4 (32)

1.380 (35.0)

1400

950

770

660

580

1-1/2 (39)

1.610 (40.9)

2100

1460

1180

990

900

16

Summary of Contents for C105-1-D

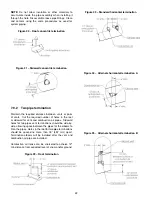

Page 24: ...Figure 26 Alternate horizontal termination C Figure 27 Venting gasket 23...

Page 25: ...Figure 28 Direct vent clearance 24...

Page 26: ...Figure 29 Other than Direct vent clearance 25...

Page 34: ...Figure 32 Single Stage PSC Wiring diagram...

Page 35: ...Figure 33 Two Stage PSC Wiring diagram...

Page 36: ...Figure 34 Single Stage ECM Wiring diagram...

Page 39: ...Figure 35 Dimensions 38...

Page 40: ...Figure 36 Exploded view CXX 1 X part 1...

Page 41: ...Figure 37 Exploded view CXX 1 X part 2...

Page 43: ...Figure 38 Exploded view Cxx 1 D part 1...

Page 44: ...Figure 39 Exploded view Cxx 1 D part 2...

Page 46: ...Figure 40 Exploded view Cxx 2 D part 1...