NOTE

: Do not allow insulation or other materials to

accumulate inside the pipe assembly when installing it

through the hole. Disassemble loose pipe fittings. Clean

and cement using the same procedures as used for

system piping.

Figure 20 – Roof concentric termination

Figure 21 – Sidewall concentric termination

7.9.2

Two pipe termination

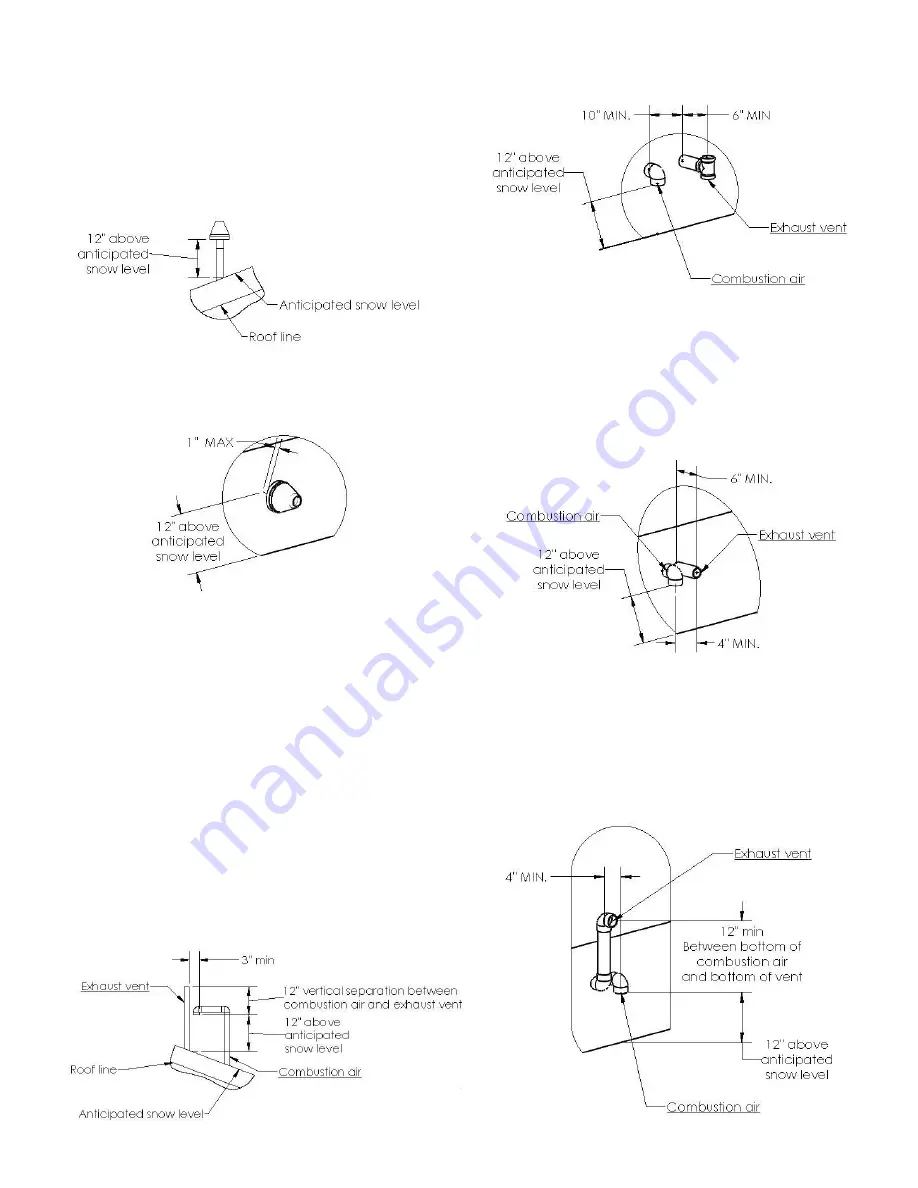

Maintain the required distance between vents or pairs

of vents. Cut the required number of holes in the roof

or sidewall for vent and combustion air pipes. Sidewall

holes for two pipes vent terminations should be side-by-

side, allowing space between the pipes for the elbows to

fit on the pipes. Holes in the roof for two pipe terminations

should be spaced no more than 18” (457 mm) apart.

Termination elbows will be installed after the vent and

combustion air pipe are installed.

Combustion air intake can be snorkeled to acheive 12"

min distance from expected level of snow and/or ground.

Figure 22 – Roof termination

Figure 23 – Standard horizontal termination

Figure 24 – Alternate horizontal termination A

Figure 25 – Alternate horizontal termination B

22

Summary of Contents for C105-1-D

Page 24: ...Figure 26 Alternate horizontal termination C Figure 27 Venting gasket 23...

Page 25: ...Figure 28 Direct vent clearance 24...

Page 26: ...Figure 29 Other than Direct vent clearance 25...

Page 34: ...Figure 32 Single Stage PSC Wiring diagram...

Page 35: ...Figure 33 Two Stage PSC Wiring diagram...

Page 36: ...Figure 34 Single Stage ECM Wiring diagram...

Page 39: ...Figure 35 Dimensions 38...

Page 40: ...Figure 36 Exploded view CXX 1 X part 1...

Page 41: ...Figure 37 Exploded view CXX 1 X part 2...

Page 43: ...Figure 38 Exploded view Cxx 1 D part 1...

Page 44: ...Figure 39 Exploded view Cxx 1 D part 2...

Page 46: ...Figure 40 Exploded view Cxx 2 D part 1...