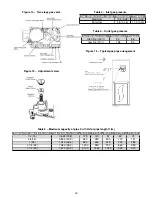

Table 17 – Error codes single stage

LED

Desription

1 flash, pause

System Lockout

2 flash, pause

Pressure switch stuck

close

3 flash, pause

Pressure switch stuck

open

4 flash, pause

Open limit switch

5 flash, pause

Open rollout switch

6 flash, pause

115VAC polarity

7 flash, pause

Low flame sense

continuous

flashing

Flame

has

been

sensed when no flame

should be present

10

SINGLE

STAGE

PSC

MOTOR

Furnaces with model number CXX-1-D are equipped

with a fixed speed motor. This motor provides ease in

adjusting the blower speeds in cooling or heating mode.

Blowers should be adjusted by the installer to match

the installation requirements so as to provide the correct

heating temperature rise and cooling load.

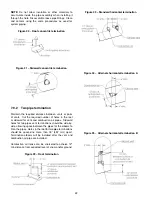

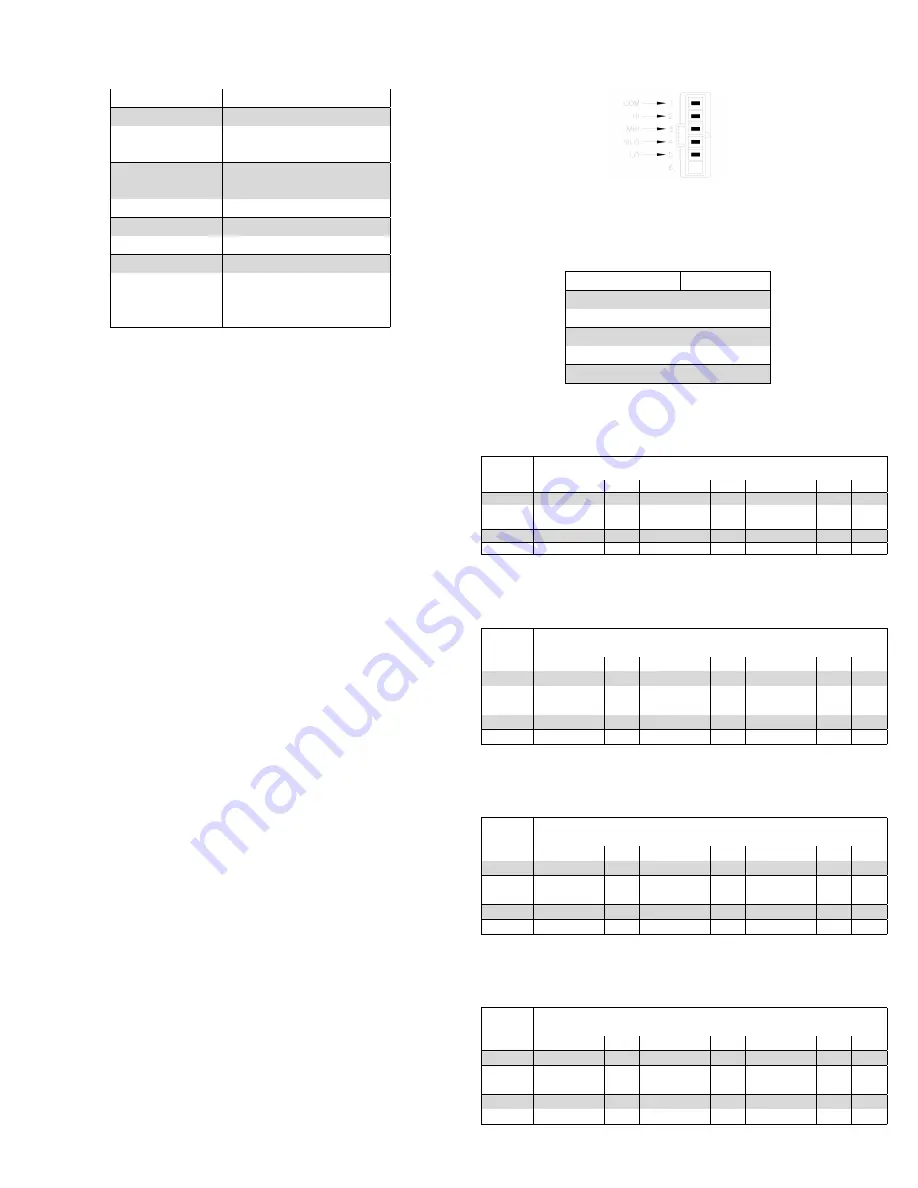

10.1

Selecting the blower speed on

PSC motor

These blower speeds are set for a temperature rise

of 55°F at normal static pressure.

Blowers should

be adjusted by the installer to match the installation

requirements so as to provide the correct heating

temperature rise and cooling load.

To adjust the

circulator blower speed, proceed as follow:

1. Turn off the power to the furnace

2. Select the heating and cooling blower speeds that

match the installation requirements.

3. Relocate the desired motor leads to the desired

speed on the motor. The red wire locate the heating

speed and the blue wire locate de cooling speed.

4. If heating and cooling speeds are the same, a

jumper wire must be used between the heat and

cool terminal on the control board. The unused

leads must be connected to the “PARK” terminal on

the control board.

5. Turn on power to the furnace.

6. Verify

proper

temperature

rise.

Excessive

temperature can cause limit switch tripping.

Figure 31 – PSC motor connections

Table 18 – Suggested heating fan speed on single

stage furnace

INPUT BTU/hr

SPEED

45 000

LOW

60 000

MED-LOW

75 000

MED-LOW

105 000

HIGH

120 000

HIGH

Table 19 – CFM C45-1-D/C45-2-D

MOTOR

SPEED

Static pressure

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

HIGH

1120

1095

1045

1020

970

915

845

780

710

640

MED-

HIGH

1047

1045

980

940

880

835

775

715

665

585

MED

935

950

910

865

820

780

730

670

600

565

LOW

930

925

875

835

800

760

710

660

605

545

Table 20 – CFM C60-1-D/C60-2-D

MOTOR

SPEED

Static pressure

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

HIGH

1374 1372 1370 1305 1230 1155 1085 1005 945

860

MED-

HIGH

1198 1195 1134 1085 1025 975

925

875

814

740

MED

1155 1150 1100 1050 1000 955

905

860

795

725

LOW

1026 1005 980

945

905

865

820

780

720

655

Table 21 – CFM C75-1-D/C75-2-D

MOTOR

SPEED

Static pressure

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

HIGH

1617 1615 1540 1440 1355 1280 1204 1182 1060 980

MED-

HIGH

1675 1670 1590 1480 1382 1300 1219 1192 1065 982

MED

1500 1496 1388 1289 1188 1133 1087 1083 1015 975

LOW

1272 1197 1148 1108 1042 967

913

824

777

749

Table 22 – CFM C105-1-D/C105-2-D

MOTOR

SPEED

Static pressure

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

HIGH

1748 1740 1615 1515 1430 1355 1285 1195 1110 1030

MED-

HIGH

1700 1655 1550 1435 1360 1285 1230 1150 1080 990

MED

1415 1405 1325 1240 1180 1135 1070 1005 930

845

LOW

1165 1130 1065 1025 975

935

870

830

775

705

28

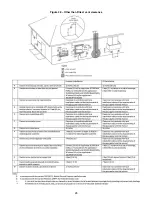

Summary of Contents for C105-1-D

Page 24: ...Figure 26 Alternate horizontal termination C Figure 27 Venting gasket 23...

Page 25: ...Figure 28 Direct vent clearance 24...

Page 26: ...Figure 29 Other than Direct vent clearance 25...

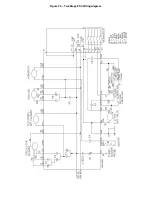

Page 34: ...Figure 32 Single Stage PSC Wiring diagram...

Page 35: ...Figure 33 Two Stage PSC Wiring diagram...

Page 36: ...Figure 34 Single Stage ECM Wiring diagram...

Page 39: ...Figure 35 Dimensions 38...

Page 40: ...Figure 36 Exploded view CXX 1 X part 1...

Page 41: ...Figure 37 Exploded view CXX 1 X part 2...

Page 43: ...Figure 38 Exploded view Cxx 1 D part 1...

Page 44: ...Figure 39 Exploded view Cxx 1 D part 2...

Page 46: ...Figure 40 Exploded view Cxx 2 D part 1...