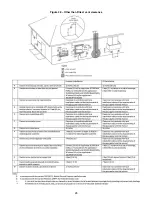

4.3.2

Side return

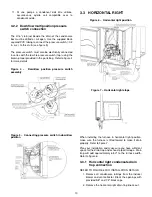

Remove 4 knock-outs on the side of the furnace of the

8 knock-outs available. Use table 3 for suggested return

size. Install the return air inlet as per local codes.

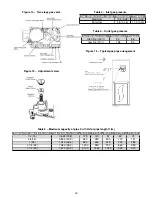

Table 3 – Suggested Filter size

Model

Filter size

15kBTU

16.00 x 20.00"

30kBTU

16.00 x 20.00"

45kBTU

16.00 x 20.00"

60kBTU

16.00 x 25.00"

75 kBTU

16.00 x 25.00"

105 kBTU

16.00 x 25.00"

120 kBTU

16.00 x 25.00"

4.4

SUPPLY AIR DUCTS

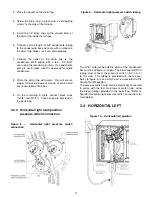

The supply air duct must be connected to the furnace

supply outlet air duct flanges.

DO NOT cut furnace

casing to attach supply air duct, humidifier, or other

accessories. All accessories must be connected to the

supply or return ductwork, external to furnace’s casing.

It is recommend that the outlet duct be provided with

a removable access panel.

This opening shall be

accessible when the furnace is installed and shall be

sized to allow the heat exchanger to be viewed or a probe

to be inserted for sampling the air stream. The cover

attachement should prevent leaks.

4.4.1

Ductwork acoutiscal treatment

Metal duct systems that do not have a 90 degree elbow

and 10 ft.

(3 M) of main duct to the first branch

take-off may require internal acoustical lining.

As an

alternative, fibrous ductwork may be used if constructed

and installed in accordance with the latest edition of

SMACNA construction standard on fibrous glass ducts.

Both acoustical lining and fibrous ductwork shall comply

with NFPA 90B as tested by UL Standard 181 for Class 1

Rigid air ducts.

5

GAS SUPPLY AND PIPING

5.1

GENERAL

WARNING

FIRE OR EXPLOSION HAZARD

Failure to follow the safety warnigns exactly could

result in serious injury, death or property damage.

Never test for gas leaks with an open flame.

Use a commercially available soap solution made

specifically for the detection of leaks to check

all connections. A fire or explosion may result

causing property damage, personal injury or loss

of life.

Gas piping must be installed in accordance with national

and local codes. Refer to current edition of NFGC in the

U.S.A.

Refer to current edition of CAN/CSA B149.1 in Canada.

Installations must be made in accordance with all

authorities having jurisdiction.

Use a back-up wrench on the inlet of the gas valve when

connecting the gas line to the gas valve.

Report to Table 6 for recommended gas pipe sizing.

Support all gas piping with appropriate straps and

hangers. Use a minimum of 1 hanger every 6 ft (1.8 m).

Joint compound (pipe dope) should be applied sparingly

and only to male threads of joints. Pipe dope must be

resistant to the action of propane gas.

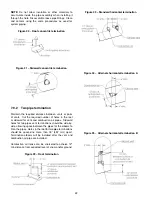

An accessible manual equipment shut off valve MUST

be installed external to furnace casing.

Install a sediment trap in riser leading to furnace as

shown in Figure 16 Typical gas pipe arrangement.

Connect a capped nipple into lower end of tee. Capped

nipple should extend below level of furnace gas controls.

Install a union between the manual shut off gas and the

gas valve in order to remove it easily.

Piping should be pressure and leak tested in accordance

with the current edition of the NFGC in the United States,

local, and national plumbing and gas codes before the

furnace has been connected. Refer to current edition of

NSCNGPIC in Canada.

The gas supply pressure shall be within the maximum

and minimum inlet supply pressures marked on the rating

plate and in Table 4.

The furnace gas valve inlet pressure tap connection is

suitable to use as test gauge connexion providing test

pressure.

5.2

PROPANE CONVERSION

To convert from natural to L.P. gas, installer should use

the appropriate conversion kit. Please refer to parts lists

in this manual.

Make sure the inlet gas pressure is as indicated in table

4.

The conversion kit consist of orifices, spring and stickers

to clearly identify conversion on the gas valve.

5.3

GAS PIPE GROMMET

For direct vent applications, the hole for the gas pipe on

the cabinet must be sealed to prevent air leakage. Install

the grommet in the hole, then insert the gas pipe.

5.4

SETTING GAS OUTLET

PRESSURE

NOTE : These furnace are high altitude certified,

elevations under 4500 ft doesn’t require orifice

change.

14

Summary of Contents for C105-1-D

Page 24: ...Figure 26 Alternate horizontal termination C Figure 27 Venting gasket 23...

Page 25: ...Figure 28 Direct vent clearance 24...

Page 26: ...Figure 29 Other than Direct vent clearance 25...

Page 34: ...Figure 32 Single Stage PSC Wiring diagram...

Page 35: ...Figure 33 Two Stage PSC Wiring diagram...

Page 36: ...Figure 34 Single Stage ECM Wiring diagram...

Page 39: ...Figure 35 Dimensions 38...

Page 40: ...Figure 36 Exploded view CXX 1 X part 1...

Page 41: ...Figure 37 Exploded view CXX 1 X part 2...

Page 43: ...Figure 38 Exploded view Cxx 1 D part 1...

Page 44: ...Figure 39 Exploded view Cxx 1 D part 2...

Page 46: ...Figure 40 Exploded view Cxx 2 D part 1...