WARNING

Corrosive or contaminated air may cause failure

of parts containing flue gas, which could leak into

the living space.

Air for combustion must not

be contaminated by halogen compounds, which

include fluoride, chloride, bromide and iodide.

These elements can corrode the heat exchanger

and burner cabinet component. This conditions

would shorten the furnace life. Air contaminants

are found in aerosol sprays, detergents, bleaches,

cleaning solvents, salts, air fresheners, and other

household products. Do not install the furnace

in a corrosive or contaminated atmosphere.

Make sure all combustion and circulating air

requirements are met, in addition to all local codes

and ordinances.

7.1

GENERAL

These furnaces are certified as either direct vent (two

pipe) or non-direct vent (single pipe).

If this furnace replaces a furnace that was connected to

a vent system or chimney, the vent may need to be re-

sized.

An abandoned masonry chimney may be used as a

raceway for properly insulated and supported combustion

air (when applicable) and vent pipes.

If more than

one furnace is installed, they must have their own set

of combustion air and vent pipes and be terminated

individually. Other gas appliances with their own venting

system may also use the abandoned chimney as a

raceway providing it is permitted by local code, the

current edition of the National Fuel Gas Code and the

vent or liner manufacturer’s installation instructions. Care

must be taken to prevent the exhaust gases of one

appliance from contaminating the combustion air of other

gas appliances. Do not take combustion air from inside

the chimney when using ventilated combustion air or

single pipe vent option.

For Canadian Installations, field supplied PVC venting

materials must be UL S636 listed. This requirement does

not apply to the combustion air pipe.

Below are important information that needs to be

considered when installing the venting system:

• The vent pipe and combustion air pipe must of be

the same diameter.

• Slope horizontal vent piping upward a minimum

of 1/4" per foot of run so that condensate drains

toward the furnace.

• Support horizontal vent piping at least every five

feet. No sags or dips are permitted.

• The vent pipe and combustion air pipe must

terminate on the same building side.

• Provide the space with sufficient air for proper

combustion using permanent pipe (direct-vent)

or opening(s) directly communicating with the

outdoors (non directe vent).

• Insulate all vent runs through unconditioned

spaces where below-freezing temperatures are

expected with 1" thick medium-density, foil-faced

fiberglass. (In Canada, per the vent manufacturer’s

instructions)

• For runs where condensate could accumulate and

freeze (including vent termination), wrap the vent

pipe with self-regulating 5 Watt heat tape. The heat

tape must be U.L./CSA. listed and installed per the

manufacturer’s instructions.

• The combustion air and exhaust terminations must

be at least 12” above grade/expected level of snow.

• Ensure the location of the combustion air inlet with

respect to the exhaust vent terminal complies with

Figure 28 and local codes.

7.2

DIRECT VENT

When this furnace is installed as a direct vent (2 pipes)

furnace, no special provisions for combustion air are

required.

Direct vent installations require a dedicated combustion

air and exhaust vent piping. The system is only using

outside air for combution.

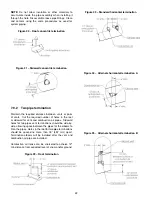

The vent and combustion air pipe can terminate vertically,

through the roof or horizontaly through and outside wall.

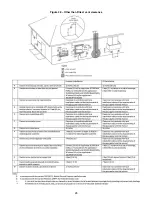

Refer to figures for approved termination.

Penetration throught a roof requires appropriate sealing

and proper flashing.

In Canada

, refer to manufacturer’s instructions for

supporting ULC S636 venting. ABS can be used for the

combustion air pipe.

7.3

NON DIRECT VENT

All air for combustion comes directly to the furnace from a

space that is well ventilated with outdoor air (such as an

attic or crawlspace). In addition, other gas appliances

installed in the space with the furnace may require

outside air for combustion.

The combustion air pipe

cannot be terminated in attics or crawlspaces that uses

ventilation fans designed to operate during the heating

season. If ventilation fans are present in these areas, the

combustion pipe must terminate outdoors as a direct vent

(2 pipe) system.

18

Summary of Contents for C105-1-D

Page 24: ...Figure 26 Alternate horizontal termination C Figure 27 Venting gasket 23...

Page 25: ...Figure 28 Direct vent clearance 24...

Page 26: ...Figure 29 Other than Direct vent clearance 25...

Page 34: ...Figure 32 Single Stage PSC Wiring diagram...

Page 35: ...Figure 33 Two Stage PSC Wiring diagram...

Page 36: ...Figure 34 Single Stage ECM Wiring diagram...

Page 39: ...Figure 35 Dimensions 38...

Page 40: ...Figure 36 Exploded view CXX 1 X part 1...

Page 41: ...Figure 37 Exploded view CXX 1 X part 2...

Page 43: ...Figure 38 Exploded view Cxx 1 D part 1...

Page 44: ...Figure 39 Exploded view Cxx 1 D part 2...

Page 46: ...Figure 40 Exploded view Cxx 2 D part 1...