7.4

SPECIAL VENTING

REQUIREMENTS FOR

INSTALLATION IN CANADA

In Canada, S636 certified primers and cements must

be used and be of the same manufacturer of the S636

venting system. Do not mix primers and cements from

one manufacturer with a vent system from a different

manufacturer. Follow the manufacturer’s instructions for

the use of primer and cement and never use primer or

cement beyond its expiration date.

All fire stop and roof flashing used with this system must

be UL listed material.

Acceptability under Canadian standard CAN/CSA B149

requires full compliance with all installation instructions.

The

authority

having

jurisdiction

(gas

inspection

authority, municipal building department, fire department,

etc.) should be consulted before installation to determine

the need to obtain a permit.

7.5

MATERIAL

USA:

Combustion air and vent pipe, fittings, primers and

solvents must conform to American National Standard

Institute (ANSI) and American Society for Testing and

Material (ASTM) and be of the same manufacturer. See

table 7

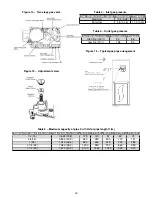

Table 7 – Approved Vent and Combustion air pipe

material USA installation

Material

Standards

PVC - DWV

ANSI/ASTM D2265

PVC schedule 40

ANSI/ASTM D1785

CPVC Schedule 40

ANSI/ASTM F441

SDR-21, SDR-26-26 PVC

ANSI/ASTM D2241

ABS-DWV Schedule 40

ANSI/ASTM D2661

Stainless steel (SS)

UL-1738

Polypropylene (PP)

UL-1738

and

ULC-

S636

All vent piping and combustion air piping MUST

conform to local and national codes.

Pipe cement must be PVC (ANSI/ASTM D2564) or

CPVC (ANSI/ASTM F493).

Primers must be PVC/CPVC (ANSI/ASTM F656).

CANADA:

Vent pipe installations in Canada must conform to

the requirements of CAN/CSA B149 code.

PVC and

CPVC vent systems must be composed of pipe, fittings,

cements, and primers listed to ULC S636 and must be of

the same manufacturer.

Combustion air pipe can use ABS material meeting the

ASTM standard D2661 / CSA B181.1.

All vent piping and combustion air piping MUST conform

to local and national codes.

7.6

SIZE THE VENT AND

COMBUSTION AIR PIPES

Furnace combustion air and vent pipe connections are

sized for 2” pipe. Any pipe diameter change should be

made outside furnace casing in a vertical section of the

pipe. Any change in diameter to the pipe must be made

as close to the furnace as reasonably possible.

The maximum allowable vent length for the vent and

combustion air pipe (when used) is listed in table 8 and

depends on the furnace input.

The maximum length

must include straight pipe and any fitting and termination.

Equivalent length of various fitting is list in table 9.

A minimum linear length of 5 ft must be respected.

To properly measure the Equivalent Vent Length :

1. Measure the linear pipe distance from the furnace

to the termination for each pipe.

2. Count the number of elbows for each pipe.

3. For each pipe, multiply the number of elbows by the

equivalent length for the type of elbow used (see

table 9). Record the equivalent length of all the

elbows for each pipe.

4. Record the equivalent length of the termination

used (see table 9 ).

5. Add the equivalent length of the elbows and

termination to the linear distance measured for

each pipe.

6. If the calculated vent length is greater than the

maximum allowed vent length (for either vent pipe

or combustion air pipe), consider modifying the

termination location or use a greater pipe diameter.

19

Summary of Contents for C105-1-D

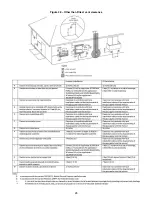

Page 24: ...Figure 26 Alternate horizontal termination C Figure 27 Venting gasket 23...

Page 25: ...Figure 28 Direct vent clearance 24...

Page 26: ...Figure 29 Other than Direct vent clearance 25...

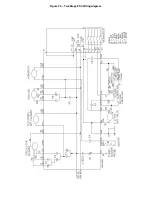

Page 34: ...Figure 32 Single Stage PSC Wiring diagram...

Page 35: ...Figure 33 Two Stage PSC Wiring diagram...

Page 36: ...Figure 34 Single Stage ECM Wiring diagram...

Page 39: ...Figure 35 Dimensions 38...

Page 40: ...Figure 36 Exploded view CXX 1 X part 1...

Page 41: ...Figure 37 Exploded view CXX 1 X part 2...

Page 43: ...Figure 38 Exploded view Cxx 1 D part 1...

Page 44: ...Figure 39 Exploded view Cxx 1 D part 2...

Page 46: ...Figure 40 Exploded view Cxx 2 D part 1...