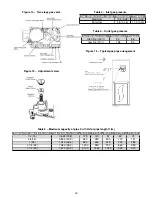

Table 23 – CFM C120-1-D/C120-2-D

MOTOR

SPEED

Static pressure

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

HIGH

1917 1915 1910 1830 1750 1675 1600 1520 1440 1350

MED-

HIGH

1893 1890 1885 1800 1735 1670 1600 1520 1430 1350

MED

1746 1745 1675 1605 1540 1470 1390 1335 1275 1210

LOW

1608 1600 1555 1500 1445 1390 1350 1310 1250 1210

10.2

Dipswitch options

Please refer to section 9.2.

10.3

Cool mode

Please refer to section 9.3.

10.4

Manual fan ON mode

Please refer to section 9.4.

10.5

Twinning Interface

Twinning furnaces is NOT recommended.

10.6

Error codes

Please refer to section 9.6 and table 17.

11

2 STAGE PSC MOTOR

11.1

Selecting the blower speed

Furnaces with model number CXX-2-D are equipped

with a multi-speed circulator blower.

This blower

provides ease in adjusting blower speeds. The heating

blower speed are shipped with the suggested fan speed

describe in Table 24. These blower speeds are set for

a temperature rise of 55°F at normal static pressure.

Blowers should be adjusted by the installer to match

the installation requirements so as to provide the correct

heating temperature rise and cooling load. To adjust the

circulator blower speed, proceed as follow:

1. Turn off the power to the furnace

2. Select the heating and cooling blower speeds that

match the installation requirements from the airflow

tables in annexe.

3. Relocate the desired motor leads to the desire

speed on the motor. The red wire locate the 2nd

stage heating speed, the black wire locate the 1st

stage heating and the blue wire locate de cooling

speed.

4. If heating and cooling speeds are the same, a

jumper wire must be used between the heat and

cool terminal on the control board. The unused

leads must be connected to the “PARK” terminal on

the control board.

5. Turn on power to the furnace.

6. Verify

proper

temperature

rise.

Excessive

temperature rise can cause limit switch tripping.

Table 24 – Suggested heating fan speed on 2 stage

furnace

INPUT

BTU/hr

HEATING

1ST

STAGE

HEATING

2ND

STAGE

45 000

LOW

MED-LOW

60 000

LOW

MED-LOW

75 000

LOW

MED-LOW

105 000

LOW

MED-HIGH

120 000

MED-LOW

HIGH

11.2

Dipswitch options

Dipswitches are used to determine :

1. Delay-to-fan-off periods. Refer to table 25

2. Second stage delay when using a single stage

thermostat. Refer to table 26

Table 25 – Heat delay-to-fan-off

DELAY

S1-3

S1-4

90 sec

OFF

OFF

120 sec

OFF

ON

150 sec

ON

OFF

180 sec

ON

ON

Table 26 – 2nd stage delay for single stage

thermostat

DELAY

S1-1

S1-2

OFF

OFF

OFF

10 min

ON

OFF

Auto

OFF

ON

20 min

ON

ON

11.3

Cool mode

In a typical single stage cooling system (Y connection), a

call for cool is initiated by closing the thermostat contacts.

This energizes the compressor and the electronic air

cleaner (optional).

The circulator will be energized at cool speed after the

COOL delay-to-fan-on period.

After the thermostat is

satisfied, the compressor is de-energized and the COOL

delay-to-fan-off period begins. After the COOL delay-to-

fan-off period ends, the circulator and the electronic air

cleaner are de-energized.

11.4

Manual fan ON mode

If the thermostat fan switch is moved to the ON position,

the circulator fan (low heat speed) and the electronic air

29

Summary of Contents for C105-1-D

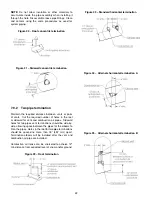

Page 24: ...Figure 26 Alternate horizontal termination C Figure 27 Venting gasket 23...

Page 25: ...Figure 28 Direct vent clearance 24...

Page 26: ...Figure 29 Other than Direct vent clearance 25...

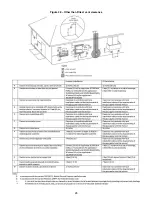

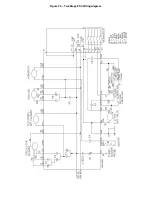

Page 34: ...Figure 32 Single Stage PSC Wiring diagram...

Page 35: ...Figure 33 Two Stage PSC Wiring diagram...

Page 36: ...Figure 34 Single Stage ECM Wiring diagram...

Page 39: ...Figure 35 Dimensions 38...

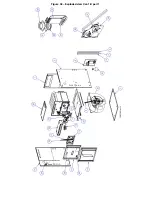

Page 40: ...Figure 36 Exploded view CXX 1 X part 1...

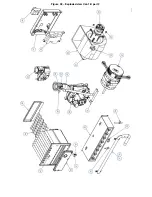

Page 41: ...Figure 37 Exploded view CXX 1 X part 2...

Page 43: ...Figure 38 Exploded view Cxx 1 D part 1...

Page 44: ...Figure 39 Exploded view Cxx 1 D part 2...

Page 46: ...Figure 40 Exploded view Cxx 2 D part 1...