efficient, satisfactory service.

However, the varied air

pollutants commonly found in most areas can affect

longevity and safety. Chemicals contained in everyday

household items such as laundry detergents, cleaning

sprays, hair sprays, deodorizers, and other products

which produce airborne residuals may have an adverse

effect upon the metals used to construct your appliance.

The cabinet of the furnace can be cleaned with soap and

water. Grease spots can be removed with a household

cleaning agent.

It is important that you conduct periodic physical

inspections of your appliance, paying special attention

to the gas burner and the flue outlet from the furnace.

These components are located at the front of the unit. A

flashlight will be useful for these inspections. Make one

inspection prior to the beginning of the heating season

and another during the middle.

Should you observe unusual amounts of any of the

following conditions, it is important that you call your

authorized dealer at once to obtain a qualified service

inspection:

• Rust, flakes, or other deposits

• Coatings

• Corrosion

Even if no unusual rust or other conditions are observed,

it is recommended that the furnace be inspected

and serviced at least once per year by a qualified

service technician.

Regular inspections and planned

maintenance will assure many years of economic

performance from your gas furnace.

14.1

CLEANING/REPLACING THE

FILTER

It is very important to clean or replace the air filter

regularly.

Dirty filters are the most common cause of inadequate

heating or cooling performance and can sharply increase

the operational costs of your unit. In some cases, they

can double the cost. The air filter should be inspected at

least every 6 weeks and cleaned or replaced as required.

Your furnace may use either a disposable filter or a

cleanable filter. The type of filter may be indicated on

a label attached to the filter.

If a disposable filter is

used, replace with the same type and size. To remove

excess dirt from a cleanable filter, shake filter and/or use

a vacuum cleaner. Wash filter in soap or detergent water

and replace after filter is dry.

Cleanable filters do not need to be oiled after washing.

Cleanable filters may be replaced with disposable filters.

If your air distribution system has a central return air filter-

grille, the furnace does not need a filter. Filter-grilles can

be maintained the same way as cleanable filters.

14.2

CONDENSATE COLLECTION

AND DISPOSAL SYSTEM

The condensate system must not be exposed to

temperatures under 32°F.

Make sure the condensate drain line does not become

blocked or plugged. Visual inspection of condensate flow

can easily be made while the furnace is operating. Use

a flashlight to illuminate discharge end of the condensate

drain that is placed in the sewer opening. The furnace will

not operate properly if condensate drain line becomes

blocked or plugged. If this event occurs, have the furnace

inspected by a qualified service technician.

14.3

ROLLOUT SWITCH

This unit is equipped with a manual reset high

temperature sensor or rollout switch.

In the unlikely

event of a sustained burner flame rollout, the rollout

switch will shut off the flow of gas by closing the gas

valve. The switch is located inside the gas burner area.

Flame rollout can be caused by blockage of the power

vent system, a blocked heat exchanger, or improper gas

pressure or adjustment. If this event occurs, the unit will

not operate properly. The gas supply to the unit should

be shut off and no attempt should be made to place it in

operation. The system should be inspected by a qualified

service technician.

14.4

SAFETY INTERLOCK SWITCH

The blower compartment door on your high efficiency gas

furnace is equipped with a safety interlock switch that will

automatically shut off your complete system (including

blower) once the door is removed.

This is for your

personal safety. Be sure to check your furnace for proper

operation once the door or panel has been replaced. If

the system does not operate once the panel has been

replaced, try removing and replacing it once again. If the

furnace still does not operate, call your dealer for service.

31

Summary of Contents for C105-1-D

Page 24: ...Figure 26 Alternate horizontal termination C Figure 27 Venting gasket 23...

Page 25: ...Figure 28 Direct vent clearance 24...

Page 26: ...Figure 29 Other than Direct vent clearance 25...

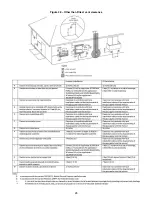

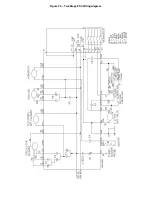

Page 34: ...Figure 32 Single Stage PSC Wiring diagram...

Page 35: ...Figure 33 Two Stage PSC Wiring diagram...

Page 36: ...Figure 34 Single Stage ECM Wiring diagram...

Page 39: ...Figure 35 Dimensions 38...

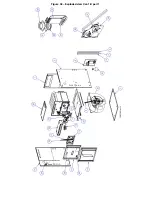

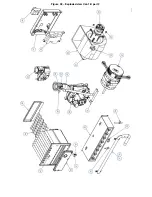

Page 40: ...Figure 36 Exploded view CXX 1 X part 1...

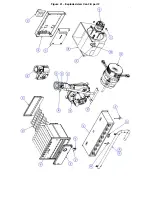

Page 41: ...Figure 37 Exploded view CXX 1 X part 2...

Page 43: ...Figure 38 Exploded view Cxx 1 D part 1...

Page 44: ...Figure 39 Exploded view Cxx 1 D part 2...

Page 46: ...Figure 40 Exploded view Cxx 2 D part 1...